Quartersawing on a Wood-Mizer

A discussion of the best techniques for quartering logs on a bandmill, with photos of the operation in progress. January 16, 2002

Question

A friend of mine makes chairs. For the back frame structure, he needs a perfect quarter saw on each board. Presently he splits logs into wedges and then squares them up on a table saw. I am looking for a way to hold the log into place so I can saw it on a Wood-Mizer. The way it's being done now is very wasteful.

Forum Responses

One method is to take wedges and attach them to a flattened side of the log to get it to tilt. I use Bondo for this job, as it hardens quickly. But that is only good for one or two cuts and then you have to prop up under the wedges to get the log to turn some more. With perfectly sawn quarter sawn lumber you are going to have to accept the waste problem, but it is worth it.

I do a bit of quarter sawing with high-grade white oak logs on a

Wood-Mizer (hydraulic) bandsaw. I prefer to start with an octagon, making all slab cuts parallel to the pith. This ensures that the pith will be parallel to the saw bed at all times. The critical thing is to produce enough flat surfaces so that each quarter can easily be turned and clamped. This method produces boards with parallel sides, which I find easier to edge and to stack. Below are some illustrations of the method I use.

Pictures and captions by Woody Green

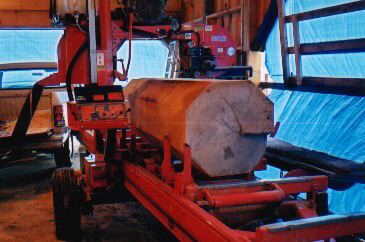

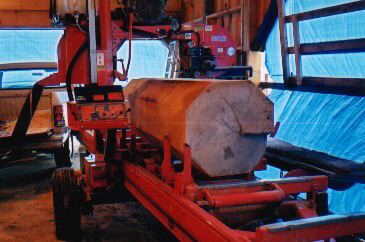

Step 1: Slab eight sides.

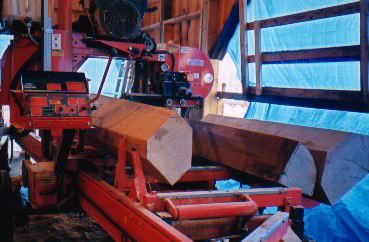

Step 2: Cut the log into quarters.

Step 3: Remove pith from first quarter.

Step 4: Rotate 90 deg.& saw halfway.

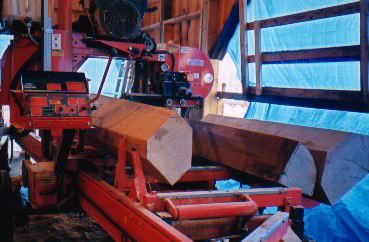

Step 5: Rotate 180 deg. & lower the 'dogs'.

Step 6: The last boards are the best!

Why not buy backing boards from a veneer mill? They are perfectly quarter sawn and of high grade.

From the original questioner:

The guy I'm sawing for wants this, and I'm just trying to accommodate him. He has to have this green, I think.

The

Wood-Mizer handbook describes a method of modified quarter sawing that is very easy to do and which provides a good amount of true quartered from the right logs. I find it works with larger logs. The log is positioned with the best possible face up and the levelers are used to center the pith (that is, the center of the log is brought to the same height on both ends). Roughly the top third of the log is severed and put aside. Flip and remove the other third and set aside. Set the center third on its side and box out the heart, leaving two pieces that will provide true quartered boards, and one center cant. The outside thirds are placed on the mill on edge giving boards that range from flat through rift, then quartered and back through rift to flat. Waste is minimized and edging is easier, since most of the flitches have one flat edge.