RTA Fittings for Fat Shelves

Suggestions for "ready-to-assemble" hardware suitable for thick shelving material in a built-in project. March 13, 2014

Question (WOODWEB Member) :

I need a recommendation for some RTA connectors for some display shelving. The material is 1 1/2 thick and Iím hoping not to have to do any end drilling.

Forum Responses

(Cabinetmaking Forum)

From contributor N:

I know Lamello makes some biscuit type RTA's.

From contributor D:

Hafele has several types of connectors that do not require edge drilling. The one I have the most experience with is the solo 32 clip connector. This is sturdy, but clunky looking, and requires only face drilling.

From Contributor B:

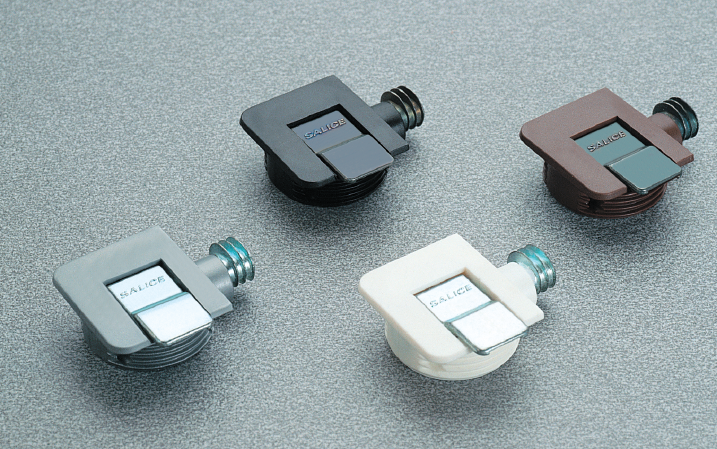

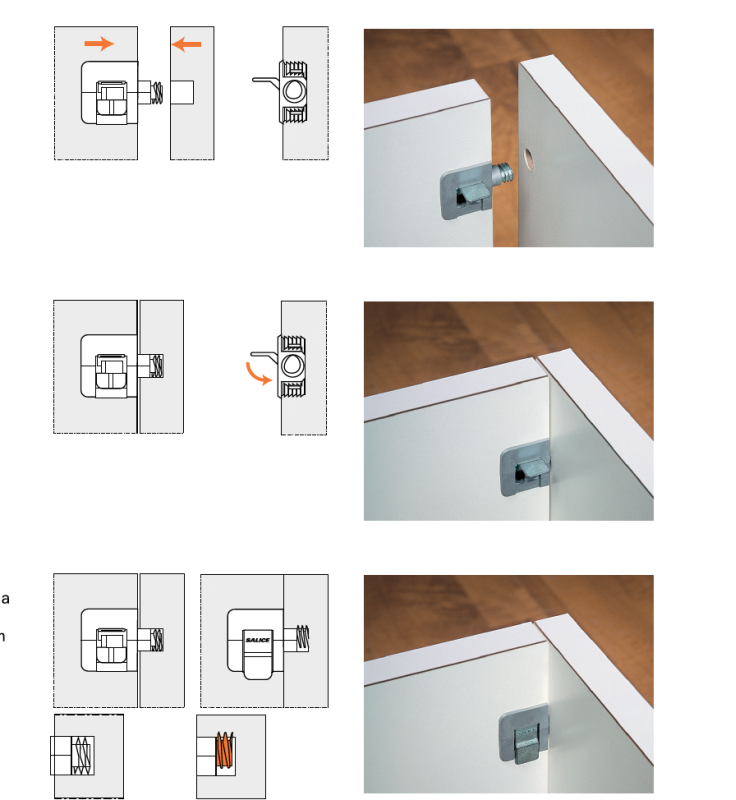

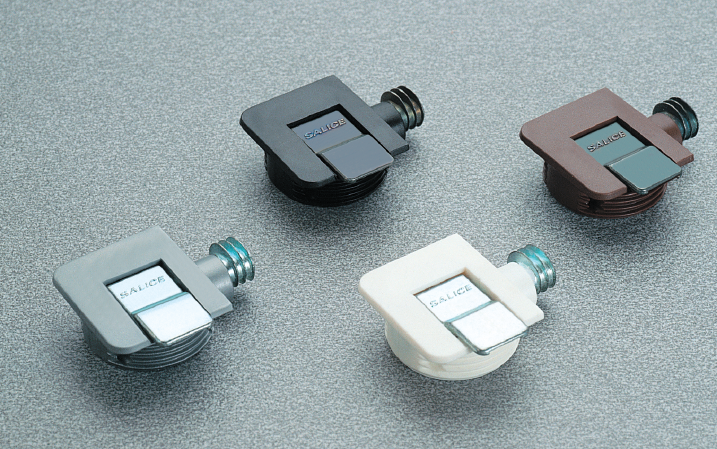

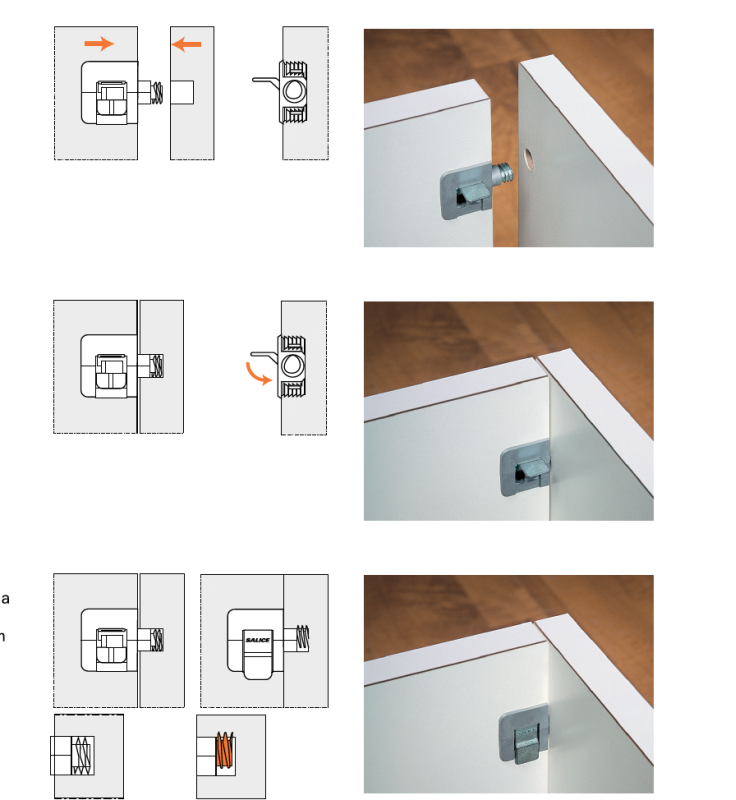

Here is a suggestion: These fittings do not require edge drilling and offer a tool-free assembly. The only limitation is that the horizontal members (shelves) need to be installed to one side first then match up the second side. They cannot be installed or removed between two fixed sides.

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor A:

Hafele's Rafix connectors would be a simple easy method for doing this with no edge boring.

From contributor V:

I'd want to be a heck of a lot closer to the center of those 1-1/2" panels than anything suggested so far. Tab 18 (for lightweight panels) and Minifix (end bore required) would get your screw/bolt 14.5mm (7/16") up from the bottom face.

From Contributor B:

I missed that 1-1/2" detail. Better clean the old glasses. I would agree with you, Contributor V. It is still a very effective fitting for 3/4" panels.

From Contributor Y:

Lamello's "Clamex-P" connector system using either a CNC router or hand held "Zeta P2" P-system biscuit joiner is great for shelves to divider partition panels. They are almost entirely invisible, they are strong, they are simple and fast to use. You don't need to end drill, however with the Zeta P2 you make a slot cut easily and precisely in the end of the shelf. Similar as the

Salice hardware mentioned, you will also need to assembled one side, then match up the second side.

Click here for higher quality, full size image

From contributor A:

If you are looking to connect horizontal shelves to verticals I would think that Rafix would provide the method of supporting the shelves and pulling in the verticals. Not sure why the bolt needs to hit the center of the shelves.