Question

In the near future I will install a cabinet job in an older home. The homeowner has asked me to recoat the existing interior passage doors. I saw them once and I think they are probably varnished 50 years ago. I can brush them with a coat of decent varnish but we know that is slow to apply and slow to dry, collecting any dust we raise while the other work is happening.

What if I coat (spray) them with precat lacquer? I can truck them back to the shop, coat them and reinstall with probably no dust and a near perfect finish just like the cabinets. Will the recoat work? Will it lift the old finish and if so what can I do to prevent that? If I take them to my shop and spray varnish (no lifting or incompatibility problems), they will take forever to dry and be right in the way for days before I dare flip them and start all over with the slow dry. If I need to use varnish then I feel I may as well brush them in place. Any ideas?

Forum Responses

(Finishing Forum)

From contributor R:

To simply add a coat or two of new varnish to a coating that you say is nearly 50 years old won’t do any justice to the brand new cabinets you’re installing. A lacquer coating be it a post or pre catalyst will more than likely lift the varnish or what’s left of it. Do what you feel is right but if it were me I would explain the pros and cons to the homeowner of just re-coating it without the proper prep work. Who knows, once they see how beautiful their cabinets are they just might have you varnish the doors in the proper manner.

It won't look like your cabinets, but could save a lot of money and they may be pleased with the results. Do a sample for them on an existing portion, so you and they have real answers as to the results.

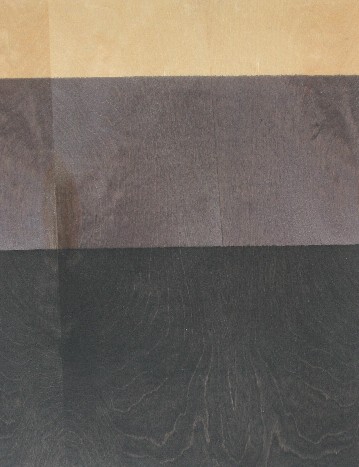

Dewaxed shellac can be sprayed on with a #1-2 cut, it dries quick, sands easily, and then can be recoated with your lacquer schedule. Some hardware stores sell it all ready mixed with denatured alcohol and the shellac.

You should also wipe door down with naphtha or minerals spirits to get rid of dirt and grime, then with 1/2 gal. water and cap full of Dawn before you start scuff sanding and re coating. If your door is in bad shape, you will still get better results by having it professionally stripped.

I bet if you cleaned and scuffed them a vinyl sealer with pre-cat top coat would be fine.

I just re-finished/painted a dresser and used shellac as the initial sealer. For me this was a mistake as the resulting surface was too slippery for the brushed on wall paint. It took three-four coats instead of two and didn't really stick well.