Two Hands Safety Control

Reprinted with permission of the Wood Machining Institute and Ryszard Szymani.

According to a recent article by John Drengerberg (2003), Manager of Consumer Affairs for Underwriter Laboratories (UL), “Power saws make any home fix-it job easier, but be careful - contact with saw blades spinning at 5000 revolutions per minute sends more than 84,000 people to emergency rooms every year.” www.ul.com/seasonal/spring/saws.html

Safe Operation Requires Two Hands on the Saw

The experts in woodworking have recognized for over half the century that safe operation of a power circular saw requires both hands to be on the saw while the saw is running. Examples of statements to this effect are: (1) National Safety Council, Accident Prevention Manual for Industrial Operations (1946), p. 406, with respect to “Power driven hand saws”: “Safe practices to be required of the operator are listed below: 1. Hold the saw with both hands;” (2) Particular Requirements for Circular Saws and Circular Knives, UL Standard 745-2-5, published March 23, 1995 ”If both hands are holding the saw, they cannot be cut by the blade” and (3) The OSH Answers, Safety Hazards, Powered Hand Tools, Saws –Circular, published by Canadian Centre for Occupational Health and Safety, Last Updated on March 28, 1998: “Use two hands to operate saws-one on a trigger switch and the other on a front knob handle.”

Unfortunately, most users of circular saws are unaware that they should always hold the saw with both hands, in order to prevent injury to their “free hand”. The common and unsafe practice is to hold a circular saw with one hand, while holding the material being cut with the other hand. A possible source of this unsafe procedure can be found in illustrations, even those distributed by safety organizations that show circular saw users holding the material to be cut with one hand and the saw with the other hand. For example, the National Safety Council’s Data Sheet I-675 Rev. 86, published in 1986, entitled “Electric Hand Saws, Circular Blade Type” shows on its first page a photo of a user cutting wood while holding the circular saw in his right hand and holding the wood with his left hand. The current OSHA website under a section titled “Handheld Saws” also displays a similar illustration.

See www.osha.gov/SLTC/etools/machineguarding/saws/handheld_saws.html, page 2 of 4.

Power Saw Design Modification: Two Hand Operating Feature

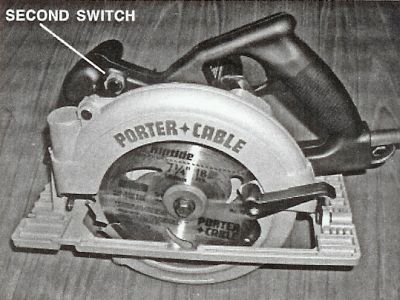

Using the two hands safety control in devices that can seriously injure users’ hands if one of them is “free” is a traditional safety measure. A simple and inexpensive way to ensure that the user must keep both hands on the power saw is to add a second switch and to wire it so that the saw will not operate unless both hands are on both switches simultaneously. I have modified the Porter-Cable Saw Model 743K that I purchased in January 2004. Specifically, I had a second switch installed on the front knob handle of the power saw (See illustration below). The modified Porter Cable Model 743K power saw, left handed with a second switch installed by the Wood Machining Institute on the LHS of the front knob handle.

The saw operates efficiently and requires both hands to run it. For this case the cost of installing this second switch on the front knob handle would be no more than $5.00 per saw for the saw manufacturers. The other safety feature that is not used or required in the USA is the riving knife as described in Wood Machining News, November-December 2001 and July-August 1996.

Reprinted with permission of the Wood Machining Institute and Ryszard Szymani.