Setting Glass into Flush Panel Doors

Attachment options for setting small pieces of glass into cabinet doors. May 24, 2010

Question

I'm doing a large kitchen - very contemporary with flush doors of MDF laid up in anigre. Many of the doors have a small 4x4 piece of 1/4" glass located in the center. I'm thinking of cutting the doors to size, machining the opening and applying an anigre edgeband to the inside, then sending them to my local panel fabricator. My problem is I don't know the cleanest way to secure the glass. The doors are all A2. Rabbet the back and silicone?

Forum Responses

(Architectural Woodworking Forum)

From contributor J:

Rabbet and silicone is quite common. Better option is to rabbet then use a slot cutter for a groove and then use glass panel retainer molding.

From contributor P:

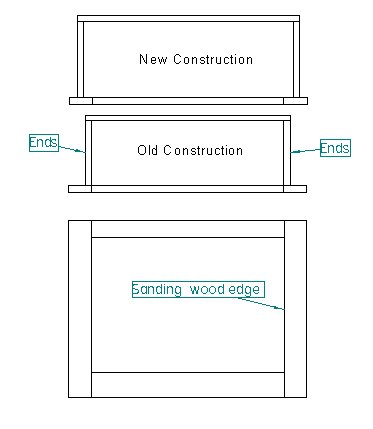

Silicone is the quick and cheap - the standard (like no one is ever going to see the other side of the door?). The plastic mold is nearly as quick and cheap, and still looks bad. The better way is to lay in a little rabbeted frame before veneering, and then stop the glass in with nice little wood stops.

It depends where you want to be on the spectrum. Remember, most people have never really seen good work, so they won't know if you don't give it to them. Give it to them, then point out what it is, and why it is better, and they will associate better quality with you, and perhaps show others.

From contributor D:

I've done it all of the above ways and maybe a few more that I can't remember. As far as quality goes, I don't really think this detail is gonna win you any friends or lose you any. Do what's clean and profitable for you. Us woodworkers get hung up on little crap like this too often, thinking it's going make or break the whole project, when in the end no one even notices. How you attach the glass is likely not going to be a bragging point to the owner (unless it falls out).

From contributor C:

All of the above methods will yield very acceptable results when executed with good workmanship and neat, clean, tight tolerances. You could spend hours pondering the right way to do something and you cannot add these hours to the job's yield. This is a very small element of the project and small items often take a disproportionate amount of labor to execute when compared to what the sales rep added for them. We try to cater to the upper few percent of woodworking consumers and it is always a challenge to get all the details into the estimate sheet prior to sale. So when an odd element shows up for the first time, give it to an efficient worker and have some confidence in his work.

From contributor V:

You can always just run a dado down the center of each rail and put the glass inside the door frame before you finish it, then finish after it is all assembled. I have done things like that before and the only thing I can say is to make sure you leave the opening for the glass wide enough. But not too wide, or it will be sloppy. Then use some glue balls (from the edge bander) and place them in there before you put the glass in. That will keep the glass from making any noise.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor S:

ďThe better way is to lay in a little rabbeted frame before veneering, and then stop the glass in with nice little wood stops." I agree with this method as the preferred option. Use a headless pinner to hold your stops in place and you've got a truly professional job.

A water based caulking would be my vote for option two. Unless you guys do a lot of caulking the ability to wipe off the overage with a damp cloth will let you do a nice job first time out. I have a glass shop nearby that will take cabinet doors and glaze them for me. Colored glazing putty if you prefer. These guys do a great job. Maybe you have a local option too. Most importantly donít lock the glass into a rabbet as you build the doors. Someday itís very likely someone will need to replace that glass and you will have left them with a major project.