Shop-Made Fence Stops for a Line Boring Machine

Here's a look at a shop-rigged adjustable stop system for a Ritter R-46, with brass bolts for fine adjustment. April 29, 2012

Question

I need to line drill some closet panels, but I don't have much faith in the older fence/indexing pins on my machine. I checked with Ritter and I can mount their newer fence on my machine, but it's north of $1600. I have the space for a fence system, but it would definitely take some usable space away.

1) What's a good fence/stop system?

2) Am I better off with indexing pins or stops?

3) Any shop made solutions?

Most of the time I'm just boring uppers and bases, so this setup would not need to be in use every day.

Forum Responses

(Cabinetmaking Forum)

From contributor J:

I had one of the early flat belt drive Ritter R46s with the pneumatic pins, and they allow for a lot of slop to creep in. The fence and stops on the Gannomat are definitely better in every way, especially on longer panels.

Check out 8020.net. Also they have a store on eBay selling seconds and overruns. Great product and the same stuff most newer machines use from the factory.

From contributor B:

I've got an older (late '80s) R-46 with an old style (flat aluminum) fence and pneumatic indexing pins. With proper setup and good air pressure, it's plenty accurate for closet panels. I don't have room for an extended fence anyhow; if one was needed, 80/20's the way to go.

From contributor D:

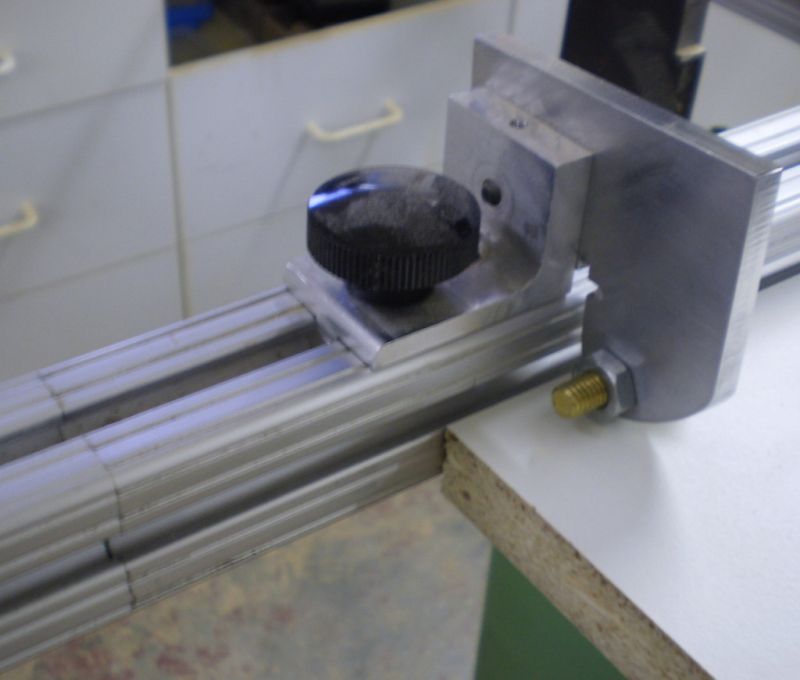

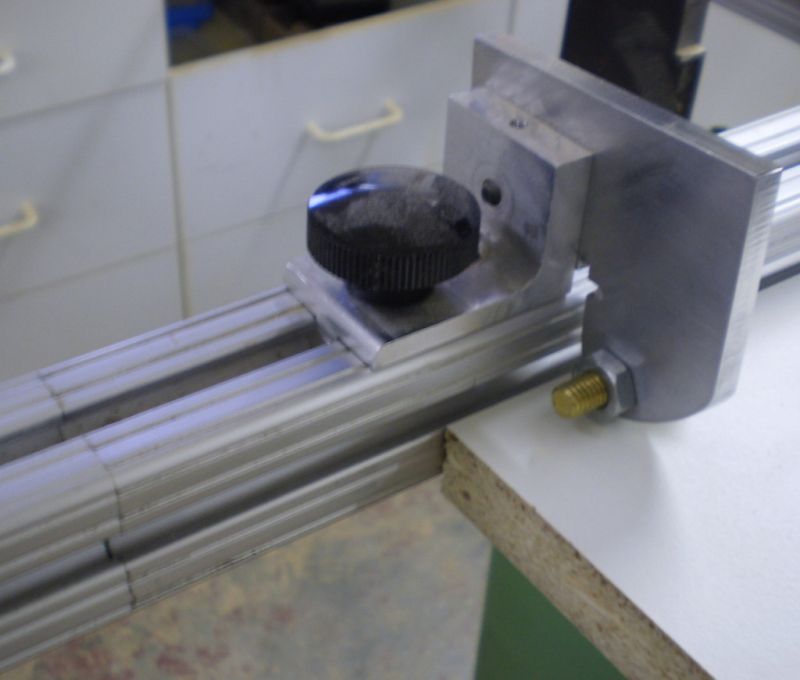

Many T-slot extrusions can be tapped and joined with a threaded stud. There's a fence extension seam visible on the left side of the images. I prefer push type stops for line boring because they're more rigid and precise than indexing pins. The brass bolts on the pictured stops make fine tuning easy (~.2mm per facet).

Click here for higher quality, full size image

Click here for higher quality, full size image

From the original questioner:

That's exactly what I'd like to do with mine. I checked out 80/20 and it was a bit overwhelming… So many piece parts. What size extrusion did you use for the fence? Were your stops off the shelf or did you have them made? Can you explain how you joined the section together so they matched up so well? I'd love to be able to remove the sections when I'm not drilling closet panels or pantry panels.

From contributor D:

I use the 1515 (1.5 x 1.5") from 8020. The lightweight is fine, but I think I'd use the regular for long unsupported fences. I just threaded the center hole on each piece (5/16-16 tap) to get the alignment you see. I was fully expecting to have to shave bits off one of the ends to get the pieces to align when screwed tight. The stops are made from cut and milled (e.g. tongue to fit the slot) 2 x 3/8" angle and 3 x 1/4" flat stock. While quality is a lot better with a milling machine, I made my first ones with a table saw, chop saw and drill press.