Question

Iím wondering if any of you out there would be willing to give me a ball park (casting a wide net) on what I would be looking at dollars wise and machine wise for an entry level profile grinder for a small shop. I would mainly be grinding W and H and corrugated knives for in-house use only. I am really on the fence with regards to doing this in house but it would be nice to be able to sharpen mid-run if needed. I would love some input on machines and what I could expect to have to invest on the used market.

Forum Responses

(Architectural Woodworking Forum)

From contributor L:

How much money depends on a lot but $6K to start. We started with a Weinig 925, their entry level at the time. It worked but I donít recommend buying a used one. I sold it and bought a used Weinig 950, a newer entry level grinder. Itís been OK. SCMI and Foley have grinders that seem like they would be ok for entry level. Iíve only been around one Wadkin. It didnít work very well but it may have been the user. Some machines wonít have enough adjustments, especially when using diamond profile wheels for carbide.

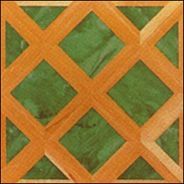

Because of the conditions grinders have to work in they can become worn and have stuck parts. Keeping it clean is a must for continued good results. Things to look for when evaluating a used grinder: smooth movement of the arbor, all adjustments work freely, the arbor diameter that your heads will fit, they are expensive. You will need to have some training in order to do a good job. Weinig offers training at their facility. Normal wear items include the grinding wheels, tracing pins of three different patterns, diamond wheel dresser, grinding fluid, filter sheets, a stone wheel dresser, template material and a means of avoiding inhalation of the fluid mist. Other items normally needed: a precision balance, abrasive cutoff saw, several widths of molder steel, a bench grinder to use in getting exact balance. We balance to 1/10th gram. You see a lot of Weinig grinders in molding shops, even when they are running a different brand of molder. Being able to make a set of knives or precision sharpen them is a great asset. We grind for the molder, shapers, arch molding shaper, rosette cutter and will soon also for the CNC router. You can make templates by hand in sheet steel (the traditional material), in plastic by hand or by CNC. Since plastic wears quickly being able to make another from the stored program is a good deal. The template has to be very smooth since the tracing pin will follow every little scratch and that will be in your knives and therefore in you molding. Being able to grind your own adds an entirely new dimension to you ability. One that weíve had fun and sales with is using two contrasting woods with one laid into the other as a separate molding.

The Viel grinder is a finesse machine that is capable of making a decent set of knives if you take your time. Loading the original template you can re-sharpen the knives quickly. The first job I did with the machine involved replicating a base cap, 5" casing with band mold, and some 8" base, (about 1500' total). I paid for the machine with that job. Personally I cannot afford a $6000 investment so I make do with what I can afford. Viel also makes a pretty good lathe duplicator for the price ($450) that saved me on a large oak mantelpiece.