Question

I need to build a solar kiln and I need to be able to increase the turnaround time on lumber, kill the mesquite and pecan borer’s, and be able to dry small cedar logs (mostly just the bark). I would like to find someone in the central Texas area that has built a solar kiln to know just how well it works for them.

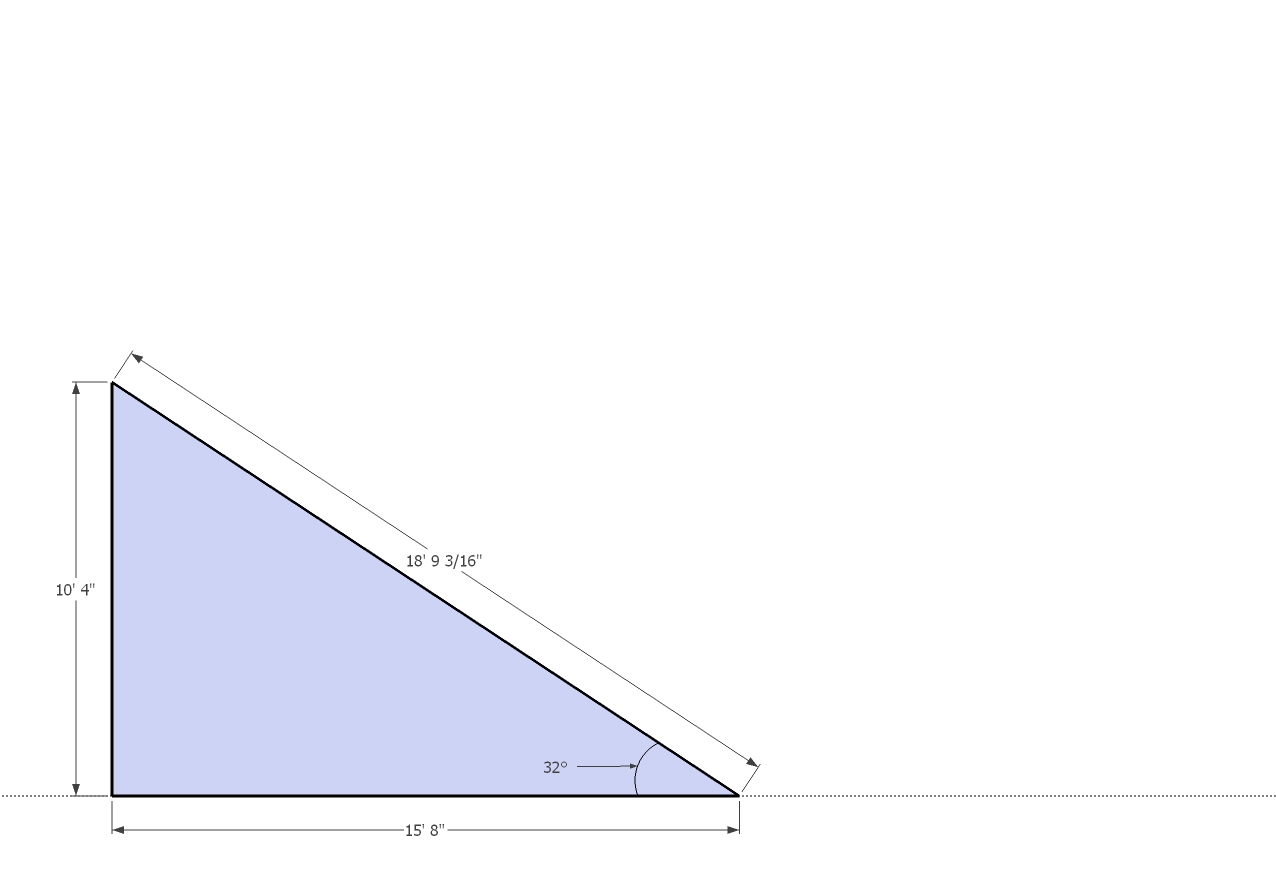

I already have an abundance of stickers that are 1 ½” thick and 32” long, so I am kind of planning the kiln around them (should I?). I am also figuring on accommodating 10 foot lumber. With my latitude at 32°, my roof angle should be 32 ° correct? Therefore, in order to get a charge of approximately 1250 bd ft (5’t x 64”w x 10’l ) into it, it would need to be 15’ 8” wide by 10’ 4” tall (north wall) by 12’ long. With the roof essentially being the south wall and ending at the ground. This would give me a total of approximately 1.5 ft²/10 bd ft if I ever did use 1” stickers, and 1.3 ft²/10 bd ft using the 1 ½” stickers. All of this is assuming a very tightly stacked charge though. If the layers are not a full 32” wide due to gaps in the lumber, then the total charge is going to be less giving a slightly higher ratio of ft²/bd ft.

1. Can I use the thicker, 1 ½” stickers, or do I need to use 1”?

2. Am I shooting for a ratio of roof area to charge that is just too high?

3. Do I need to increase the roof angle to say 38° or maybe 42° to increase the winter performance, and possibly decrease the summer-time performance? Stretches of 100° days are common here.

Thanks in advance for all of the help. Any “recommended reading” would be greatly appreciated as well. I have already reviewed “Drying Hardwood Lumber”, “Drying and Control of Moisture Content and Dimensional Changes”, “Processing Trees to Lumber for the Hobbyist and Small Business”, and “The Appalachian Solar Lumber Kiln”(which is the basic design that I am considering) plus many other smaller posts and such on the web.

Forum Responses

(Sawing and Drying Forum)

From contributor O:

Wood-Mizer sells a kit complete with detailed plans, and the roof is at 45. I think the exact angle is important with solar panels but with a kiln the light just has to pass inside to be absorbed by the black interior and the angle isn't as critical as just being open and unobstructed. Be sure you’re facing south. I use 1" stickers. 1.5 isn't necessary and would waste a lot of kiln space in my opinion. Even with 100 degree days you will probably need supplemental heat to kill borers.

Of course, all solar designs require solar input, so on cloudy days or in the wintertime when daylight is short and outside temperatures are low (what little heat you get from solar is used to heat the kiln rather than do any drying), there is a strong case for using a DH kiln or similar to provide dry lumber year-round. Remember that in all common drying systems (solar, air, DH, steam, etc except vacuum) the wood dries because of the heat, humidity and velocity. So, if there is a good combination of heat, RH and velocity that can provide superior quality, then a DH or other kiln can be operated to provide the same conditions to achieve the same drying results. The lumber does not know the source of the heat, RH or air flow.

Of course, sometimes the equipment is not operated in a good manner and then quality loss can occur. It is well to remember that prior to the recent decline in wood manufacturing we were drying about 5 billion BF of oak and other furniture grade hardwoods every year and making excellent furniture. The quality loss with proper operation was minimal and the wood processed without major problems (except for inherent , non-drying issues such as crossgrain, bacterial infections, etc.).

Be careful of claims made with any system. Make sure that they have the same species, thickness, MC, etc. and that you see it yourself. Remember, some people claim that a Dodge Ram is better than a Ford F-350; it is not true of course; those who claim so are biased and refuse to admit that they made a mistake.