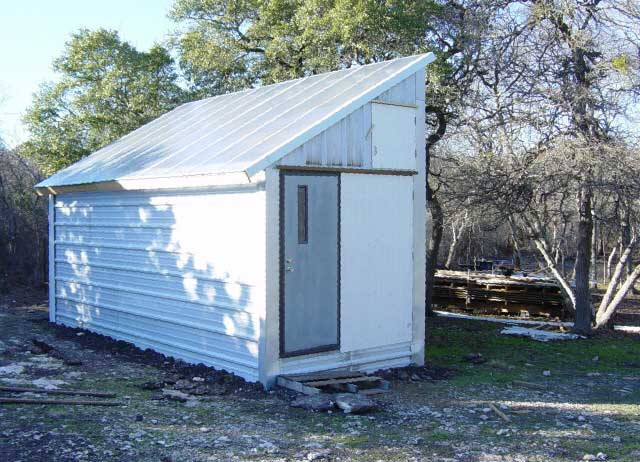

Solar Kiln Show and Tell

Photos and descriptions of small solar kilns. August 31, 2005

Question

Here are some pictures of my kiln project. Does anyone know of a company who sells a corrugated plastic ridge cap that will match the 45 degree angle of my roof below? Any help is appreciated.

Click here for full size image

(Sawing and Drying Forum)

Forum Responses

From contributor J:

Great job on the kiln - are you going to insulate it? What color are you going to paint it? What type of wood is that made of, and is that a finish on that wood? You can order a piece of flashing from a roofing supply that will bend nicely to the angle of your roof. Are you going to double glaze the top?

From the original questioner:

I plan on insulating the walls with paper backed fiberglass insulation then cover the inside with 1/4 inch Luan and paint it flat black. The roof will be corrugated plastic and the second layer of glazing will be polyethylene .The wood siding is eastern red cedar we milled, surfaced, and tongue and grooved. The finish on the cedar is clear deck finish.

From contributor K:

I agree with Contributor J. Sixteen feet of copper or aluminum flashing bent to create the angle by clamping half of the metal between two boards and fold over the material to create your angle would work well. The kiln looks good. Did you run all that wood through a planer?

From the original questioner:

All of the cedar was planed both sides and jointed one edge and ripped out random widths and tongue and grooved using the dado blade on the tablesaw. I haven’t decided what material I will use for the roof. Does anyone have any suggestions?

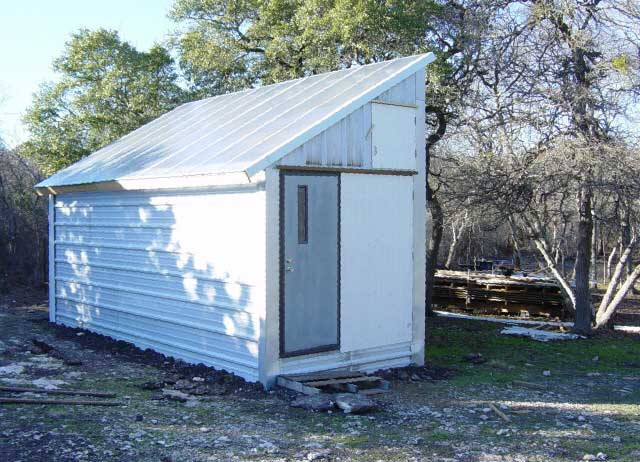

From contributor B:

I used double wall polycarb. The sheets were 4'x10'x1/4" and worked real well. I am reaching 150+ degrees now on all days that are not cloudy. Here is a site you can check some out - I found this then found a local supplier and saved on shipping. Also below is a picture of my kiln.

https://www.sundancesupply.com/index2.html

Click here for full size image

From the original questioner:

Is polycarbonate similar to plexiglass?

From contributor B:

No. It is lexan - what they make the bullet proof windows out of. My roof is made similar to corrugated cardboard with two lexan sheets about as thick as a regular sheet of paper 1/4" apart and ribbed together with ribs about every 1/4". It will last the longest of any roof except maybe glass. It is double wall for added insulation.

From contributor J:

You can see how I did mine here below. I used uv resistant greenhouse plastic underneath the fiberglass panels to get my "ouble walled roof.

http://www.geocities.com/dualsprings/ducktangpage1.html