Solid Wood Octagon Table Top Failure

Wood movement dooms a solid wood "sunburst" table top, and we learn why that will always happen. February 12, 2007

Question

I am building an octagon end table for a customer and have it totally built and ready to go. There was about a week of time where I had moved the table from my shop (unheated insulated building) to a basement. The top is 8 pie-shaped pieces glued together with biscuits. The base is enclosed with frame and panels. Well, the project kind of stalled and everything was fine while sitting in my shop... Then I moved it to the basement away from the dust where it sat again for a week or so until I could finish it. When I went back, the top was like a shallow bowl. I don't know what to do. I need to get it flat again. What can I do to prevent this in the future? The whole problem (I think) is that it's an octagon and I wasn't sure what wood movement was going to do. It's made of solid maple. And I don't want to start from scratch or cut it up again if at all possible.

Forum Responses

(Furniture Making Forum)

From contributor T:

Which way does the grain run? Is the maple 1/4 sawn or flat sawn? How thick is the top? How is the top fastened to the base? What was the moisture content of the maple? Many things to consider when building a piece like this.

From contributor W:

Are you saying that the top is basically a sunburst, but made out of solid wood? If so, and the grain runs radially (from the center out toward the edges), I would expect each pie wedge to expand and contract across its width, with more expansion/contraction happening out toward the edges of the table where the wedges are wider. If the top is built as described above, I'm not sure you can avoid this bowl shape phenomenon. This is why sunbursts are typically done using veneer on a stable substrate. I've never heard of anyone doing a sunburst in solid wood, but I could just be ignorant, too. Do you have the capability to do a veneered top? I know it sucks to do it over, but... If it's not basically a sunburst out of solid wood, please describe it for us.

From the original questioner:

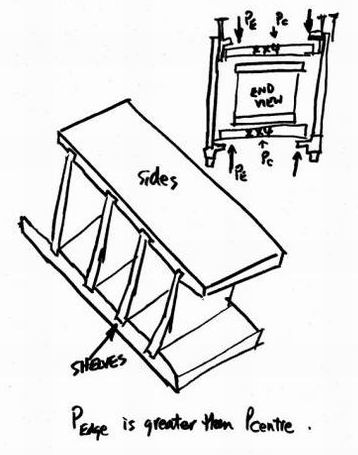

You nailed it... The grain runs radially, it's a 3/4 inch thick top, flat sawn. Right now it is fastened to the top via Z shaped clips. Unfortunately, I don't know the moisture content and I also don't have the equipment to do a veneer top. I knew I was going to be in trouble when I started this top but had to try.

From contributor J:

About 6 years back, the widow of a friend of mine gave me the pieces of a solid cherry 60" octagonal dining table that he designed the same as yours. Half of the 1" thick top was glued together already, so I figured I could glue the rest together and use it at our place. She had suggested we sell it, but I could tell by the design that it would self-destruct. Sure enough, the first time a Santa Ana wind came through, the moisture dropped and there was a 1/2" opening ripped in the top. When the humidity goes up, it closes. Sorry, but the only way you are going to accomplish this design is by using veneer on a stable substrate. The bowl shape is bad enough, but just wait until the solid wood decides to tear itself apart. It's good that you discovered this problem in your shop and not at your client's place.

From contributor B:

Interesting! Would it work if the grain was to run side to side? It probably wouldn't technically be a sunburst pattern, but would it be stable? I'm talking about using solid wood again.

From contributor P:

It won't work if made of solid in 8 pieces no matter what direction the grain runs. It would be easy to make it out of solid with all the boards edge glued parallel and simply cut to an octagonal shape, although not as interesting looking. This would work as long as you accommodated movement across the grain when you fastened it to the base.

From the original questioner:

I would like to thank you all for your responses. I have decided to rebuild the top with straight boards. I see the problem now. I love the look but couldn't see the physics part of it. Veneer next time, once I learn how. Thanks to all of you. I love WOODWEB.