Question

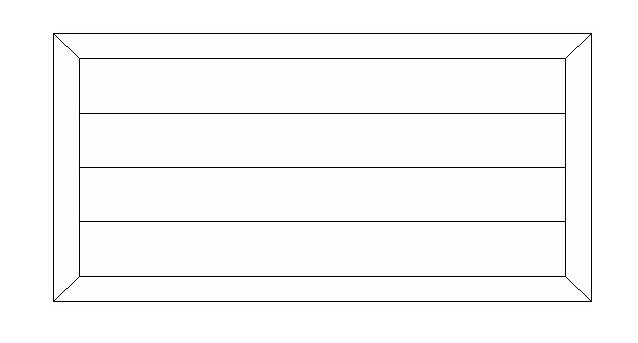

The company that I work for makes custom tables. One of the designs they want to introduce is a framed table top (see picture). It would be easy enough using some plywood or particle board, but they want to use solid wood. The obvious problem is that when the center boards expand and contract, the mitres will blow apart, or the center boards will split. Can anyone make any suggestions on how to make this work? I have suggested leaving the two center boards floating, but this may compromise strength since these tables are up to 10’ long x 50” wide.

Forum Responses

(Furniture Making Forum)

From contributor A:

The question that you should be asking is not how you can best do this. You should be asking those who want to make it this way why they would want to take on the risk and headaches that follow making a big solid top this way. Those miters are not worth having to deal with a dissatisfied customer in the future. My advice is to try to talk them out of it. If they insist on a miter, then I would insist on using a veneer.

I mean no disrespect, but for your company to ask the question shows a disregard for some of the most ancient technical information developed on this planet. No finish, no species, no magic tricks will avoid the obvious. Veneer of some sort on a stable substrate, or solids with enough room to move.

So-called primitive people 5,000 years ago used the inevitable expansion of wood to slab off 4 ton chunks of stone in quarries to build whatever they wanted. Lots of small wood wedges, dried down by fire, placed in shallow holes in the stone, water is then dripped on the wedges, they swell and exert tremendous, even pressure along the line of holes, and crack the stone. Primitive.

Cut "planks" of baltic birch or MDF, laminate your veneer onto them. Be sure to laminate BOTH sides with your "shop veneer". Now glue your "shop veneered" planks together to form your table top.

1/8" thick solid wood will not force the 1/2 or 3/4" substrate to move, i.e. it will be dimensionally stable. Also, 1/8" thick wood veneer will withstand a lifetime of refinishing, as well as most burns, gouges, and dings. I built a very large dining room table this way using Pao Ferro over birch plywood about 25 years ago. I had a chance to visit it about 4 years ago. Not a hint of movement or separation in any of the boards.