Question

I am looking for some help with a problem that Iím having and I can give some background on my setup first. I am using Fhure 350 HV for the finish and mixing their universal stain as a toner, with a ratio 16 oz of finish to 2 oz of stain.

I sand to 180, spray one coat of sanding sealer Fhure 360, sand to 220, and put on the tone finish. I am spraying with an Asturo BBS with a 1.7 tip at 20 PSI with the gun. Wet mill is between 3-5 mill for sure. I have an inline air and water filter before the regulator. The gun is clean and the pattern is good.

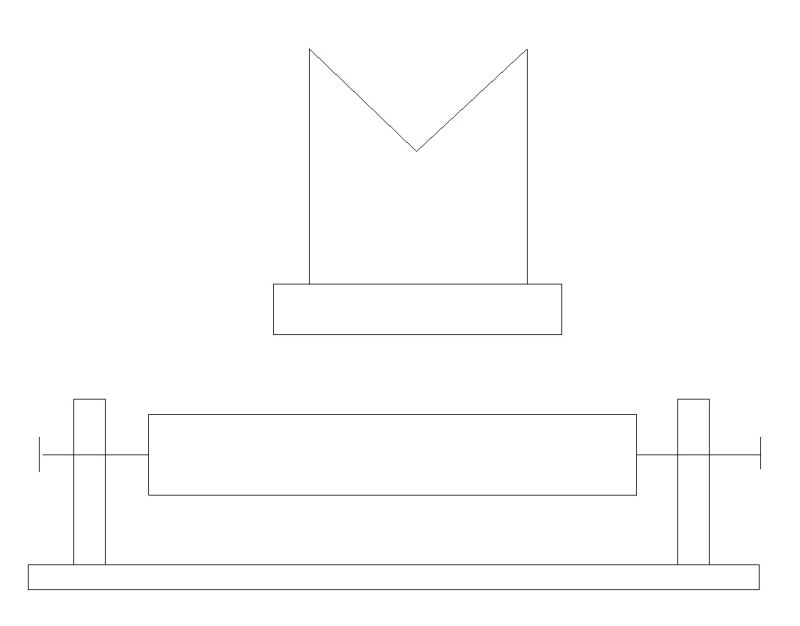

Now for the problem: With the first coat of toned finish I have a lot of that have water or wax left on the surface. I donít use serrated sandpaper, and the filter captures the water. Any ideas would be greatly appreciated. Iíve included a picture if it helps.

Forum Responses

(Finishing Forum)

From Paul Snyder, forum technical advisor:

I can tell you how to avoid the problem. Kick up the air a little (23-25 PSI), turn down the fluid, back the spray gun away from the surface an extra inch or two, and spray as thin a wet coat as you can. It may also help to reduce the stain by half (I'd normally use 2 ounces of stain per quart).

Spraying a normal full wet coat allows the finish to pool and puddle as well as penetrate any pin-holes in the sealer, and the color in the toner shows those imperfections drastically. By spraying as thin a coat as possible, the toner/color will not pool or puddle or seep into pin holes. If needed, spray more than one coat of toner to build the color you want (I always try to stick with one toner coat to make life easier).

Contributor M - The spots do not have any texture to them. When I put my finger over them you could not tell that there was anything there. I do mix well and strain my finish/toner with a 190-micron filter from Gerson. The stain that I am using is a dye base and mixes well, so I have not been double straining. When I try another batch I will defiantly strain twice.

By moving faster, you're basically doing the same thing as turning the fluid down; getting less fluid on the surface. If you can control it well, it'll speed up the process and achieve the same result. Basically, your goal is to just "fog" the toner on enough to wet the surface evenly. Don't sand the toner and apply a coat or two of clear over it for protection.