Stabilizing a Flimsy Cabinet

Ideas for reinforcing and/or anchoring a topheavy cabinet design with inadequate bracing. January 11, 2008

Question

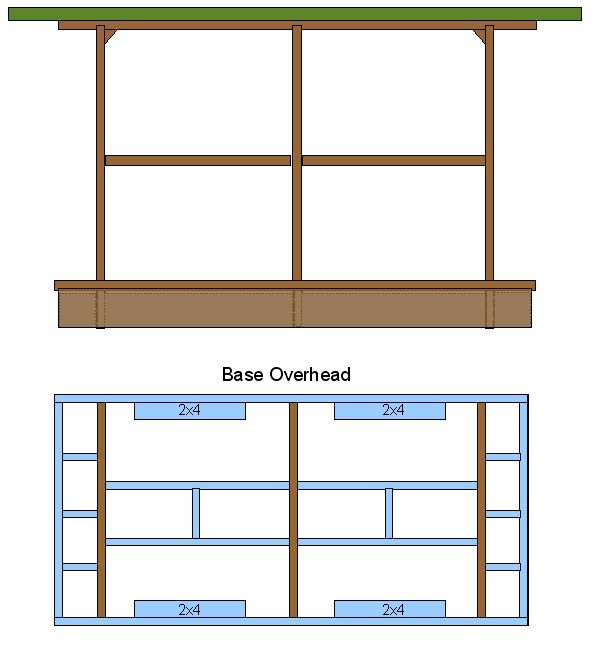

I have a customer who has sent me a design for a store fixture that is totally unstable, and I can not seem to get the customer to understand. It is a free standing store shelf unit with 3 vertical panels, a top and bottom, and adjustable shelves (shelves not shown in drawing). There is no back because the store wants to be able to see through the unit, for some reason. It really needs a back panel of some sort to make it sturdy. To make matters even worse, they want to put granite on top of the unit to use as a table top. I have offered to build a small prototype to show him how unstable it is, but I hate to take the time to build this like the customer wants me to, knowing that it will not work.

Click here for higher quality, full size image

Forum Responses

(Cabinetmaking Forum)

From contributor R:

Tell the customer that if you can make the shelves fixed (dadoed, screwed, and glued), then you can guarantee the product. If he insists on his own design, then he must take any responsibility for any flaws that the cabinet has structurally due to that design.

From contributor P:

A foot of granite overhang on a 3' base won't work on this box. If it's a laminate top and it's used for displaying sweaters or something, then you could make it work by using good 3/4" ply and fixing those middle shelves. If this is for a retail clothing store, they tend to go through displays on a regular basis, so I'd do it as drawn, with the middle shelves fixed. I'd also attach the top and use it as a stressed member. But no granite, not on that design with that much overhang.

From contributor E:

I would certainly walk away, because as drawn, you'll hear from somebody's lawyer one day.

From contributor I:

Put a face frame on the front and back - that will sturdy it up.

From contributor D:

It seems to me that since there is an equal amount of cantilevered granite on both ends, the issue is not about whether the granite will topple the piece due to an unbalance load. I would be concerned with a high center of gravity. If the center shelves could be fixed and the unit could be bolted to the floor, maybe it would work. The rotational affects of shear may need to be addressed with a face frame or a back.

From contributor K:

Two different ways I would approach this...

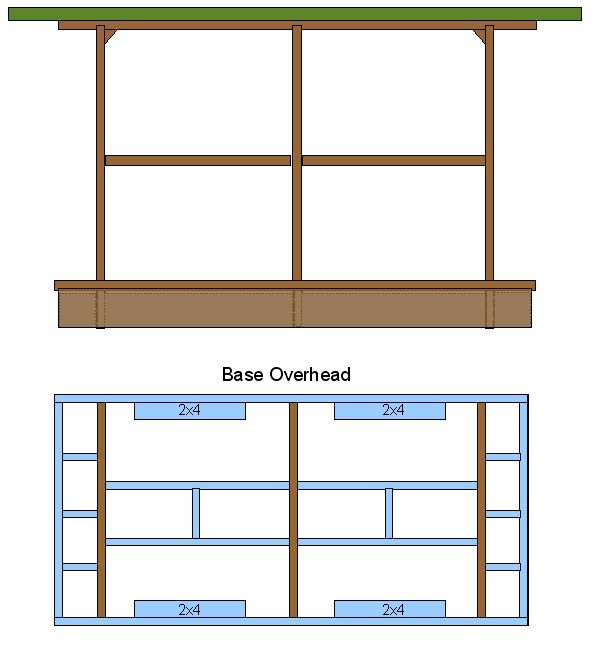

1. Add a base with counterweight in the bottom, with the sides and center panel going down into and attached to the base, which is a torsion box, which can be counterweighted, as well as attached to the floor via 2x4's. Floor of the shelf unit will slide over top of three panels and then be secured from underneath, and the three panels (left, right, center) will be dadoed into the top of the unit, then screwed and glued from the top. You can add a counterweight by adding a bottom piece to the torsion box. Corner blocks on the upper section (where it can't be seen) will add to the support. Corbels should also be used to support the granite at 12" out.

2. If he doesn't want corbels, still make it with the base, and reduce the overhang to at least 8". Otherwise, get him to sign a waiver for the granite.

Click here for higher quality, full size image

By the way, doing it this ways allows you to have adjustable shelves...

From contributor S:

It seems like you have a large overhang on both ends. Could you add a diagonal gusset from the counter down the outside of the unit? It would take care of the side to side racking problem. They would still be able to see through then. If you build something like this, glued and screwed, dadoed, etc., it will still give you problems down the road. When people move display units around, they grab hold and drag it over the floor. Guess what that does. Common sense dictates you should get several people to lift and carry, but with a granite top, then what?

From contributor K:

The above assumes this will be a fixed unit (i.e. - attached to floor). If it is a movable unit, the original design must change. My guess is that if it is a movable unit, the clerks would lift it by the top. Please specify if it is movable and that will determine if there are any changes...

From contributor F:

Great solution running the verticals down into a weighted base, contributor K!

From contributor L:

If you make it, you are responsible. You can have them sign anything you like but it won't take the responsibility from you in court (when the granite top falls on someone as the entire unit folds after having been drug across the carpet ten times). I like the outside gusset idea, but the granite top would still bother me on this size base. Are you incorporated with little value in your corporation and a good lawyer?

From contributor O:

I think you are worried about it folding up. Some little corner blocks on a 45 degree, in all top corners, will be fine, and the FF on both sides is a good idea. It will take solid concrete to make a weighted base that actually helps. I say attach it to floor. Let me guess - they want it on wheels.

From contributor K:

As laid out above, it assumes it is stationary and not going to be moved (hence the 2x4's attaching it to floor). If it is to be movable, I agree, it needs to be changed, and since we haven't heard back from the questioner on this point, we have to assume it's not movable.

A 30" x 60" granite top is going to weigh in at approximately 185-210lbs, depending on the granite, which can be easily offset in the base with standard weights, along with the fact that it is going to be attached to the floors with screws, which can negate a third of the weight necessary.

After adding a base, we are only talking about 2' of exposed vertical panel, which each panel supported on each side at the base by the torsion box, as well as the bottom of the unit. One other thing I would probably add is a horizontal support in the middle of the top section, from sides to middle. It is at the top, and you would have to bend over to see it, and being that it would be in the middle, you can still add whatever they are going to hold from each side and still see through. If you did add a face-frame, this should be overkill at this point.

One thing we can all agree on is that as originally designed by the customer, it won't work. Only way that design would work and still be movable is with a steel frame encased in ply. Even if it was movable, it would still need to be attached to the floor. If he wasn't willing to reduce the overhang to 8", or not use corbels for support, I would still have him sign a waiver.

P.S. Thanks, contributor F - glad you like it. Coming from you, that means something.