Staining Mahogany Plywood

Tips on bringing out the grain in mahogany. October 19, 2005

Question

I recently cut some shelves from two plywood sheets of mahogany and veneered the edges. On a test sample I used a brushing and wipe-off stain, however I lost all of the subtle grain-like highlights and large grain colors. They all turned to the same color and the only darker parts of the wood show the speckled surface grains. I have read the Knowledge Base entry for mahogany, however I have not found a solution. I am thinking of using a spray stain. Can someone please advise what prep process I should take to preserve the highlights and larger wood grain colors? Also what stain would be best for this application?

Forum Responses

(Finishing Forum)

From contributor A:

Water based dye stains are what you are looking for. They will highlight the figure in your mahogany.

From contributor B:

What brand of stain did you use? Stains hide grain detail when they are really heavy in low grade pigments. Are you trying to achieve a dark color? Try Mohawk penetrating oil stain available in three colors: BR mahogany, RD mahogany and walnut. It is a dye stain designed for wiping applications. My finishers achieve wonderful clarity with rich color. Dye stains of any kind generally have better clarity in my experience.

From the original questioner:

The color I am trying to achieve for the shelves is a dark espresso with a reddish tinge, with the figure of the wood nearly black. The figure is what I am trying to retain. Prior to using a water based stain do I need to prep it any more than 180-220 grit?

From contributor B:

Perhaps you could try some combination of Burnt Umber, Burnt Sienna wiping stains or dye stains with a little red tint if necessary. Follow with a wash coat and some black or Vandyke brown glaze to help with the grain. Thin the glaze with naptha and if you don’t like it immediately you can easily wipe it off with more naptha. Most colors can be achieved using burnt umber, raw umber, and burnt sienna and the primaries. Everyone here knows the value of samples.

From contributor A:

180 grit is fine for prep. Start with a base of something from Lockwood’s oak line for a base color, mix in as much red as you like with standard mahogany #54 and add pinches of black to obtain the espresso you are trying to achieve. Oil based stains and dyes have their place, but if you really want to get that translucent look, water based dye stains are the only way to go.

From contributor B:

In my experience, the quality of a finish depends on the finisher. Whether you use water based or oil based, you will need practice.

From contributor C:

The key to getting good clarity with pigmented stains is wiping or spraying the stain on, and then wiping it dry.

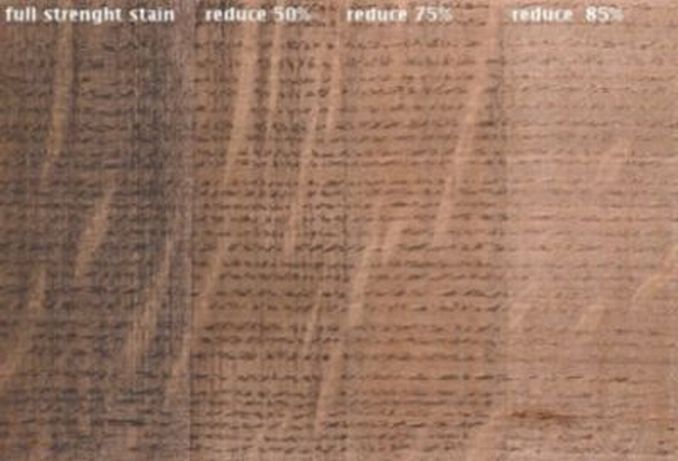

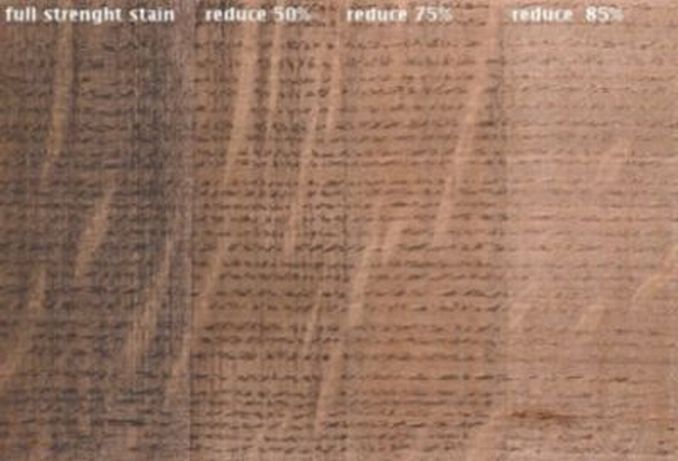

You need to start, by making up a complete coated sample to see the true color. Depending on the stain you use, and the final color you want to achieve, you may have to dilute the stain. These dilutions will give you other colors.

Manufacturers use this same process to make up their colored stains.

View full size image

From contributor D:

It sounds like you are looking for a lot of contrast between the grain and the rest of the wood. One way to accomplish this is to lightly stain with a water or alcohol based dye, then seal with a clear seal. Then, stain with a dark pigmented stain or glaze and wipe off completely so the pigment stays in the grain but is wiped off everywhere else. Pigment will accent the grain as long as it is mostly wiped off everywhere else.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor E:

Even some Honduras mahogany will take stain unevenly. First dye the bare wood to an undercolor lighter than the desired tone. Lightly sand off the raised grain and then seal with seal coat shellac (seal coat/alcohol 1:1). Then apply wiping stain of your desired color or darker as need be. Wipe off only enough to achieve the desired color and then finish with finish of choice.