Step-Stool Strength Issues

Furnituremakers consider the stresses on a two-step stool. January 23, 2012

Question

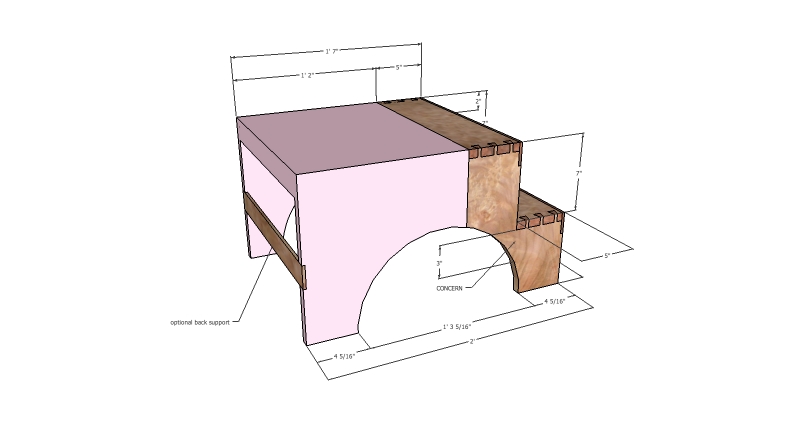

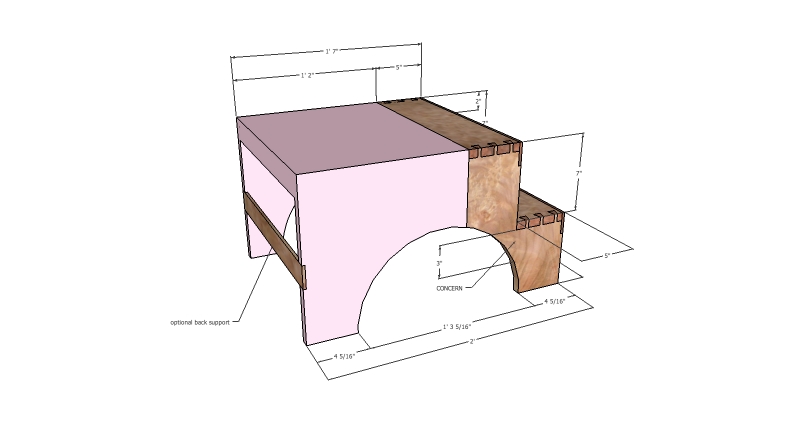

I've designed a stool for a client and am concerned about the strength of the wood legs. The stool is made from solid maple. I have hemi-spherical cutout along the sides shown in the drawing below. I just want to make sure that the piece isn't going to fail at that point. The side of the steps can be either one piece or a glue-up. The back support piece is also optional. Iím not sure if it is necessary to keep the box square.

Click here for higher quality, full size image

Forum Responses

(Furniture Making Forum)

From contributor Y:

Be careful about the material you use for the piece. Run the grain a bit on an angle so that you have the long grain on a bias to the top. Or just change the radius or centerline of the cutout so that you have continuous long grain to the floor.

From contributor J:

I think you're right to be concerned on both counts. The semicircular cutout, as drawn, creates a serious weak spot, and you do need some sort of reinforcement similar to your "back support piece" to prevent wracking. If you're going to do this from solid wood then the grain of the side pieces must run vertically so that the parts all move together. That means the likely break will be a vertical split extending straight down from the back of the first tread to the cutout. Make the cutout smaller and/or move it towards the back so that it's away from that area.

From contributor O:

You seem to have no diagonal bracing to speak of. It will collapse to the right or left as a person ascends if (when) they shift their weight to either side. It needs either diagonal struts or a substantial vertical transverse diaphragm. The tiny amount of diagonal bracing shown at the front of each step, at the back edge and as offered by the back crossbrace appears way too little.

From the original questioner:

An alternative that I was working on had the back extend down to the floor. This would certainly help with racking and diagonal forces. I think that based on the opinions, I will decrease the radius of the circle and may move it towards the back of the stool.

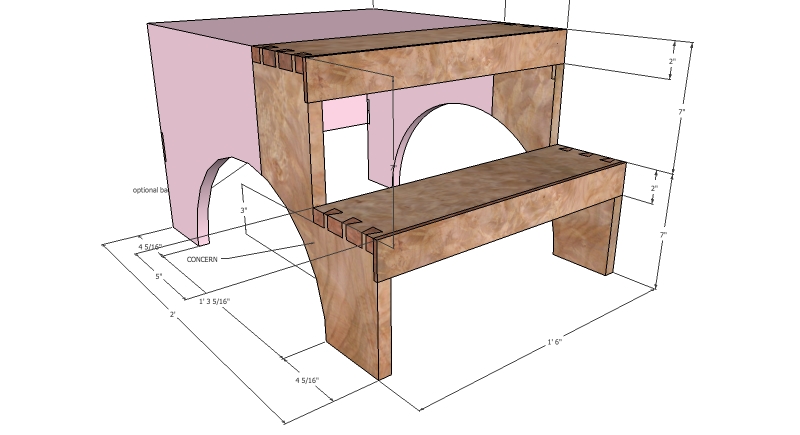

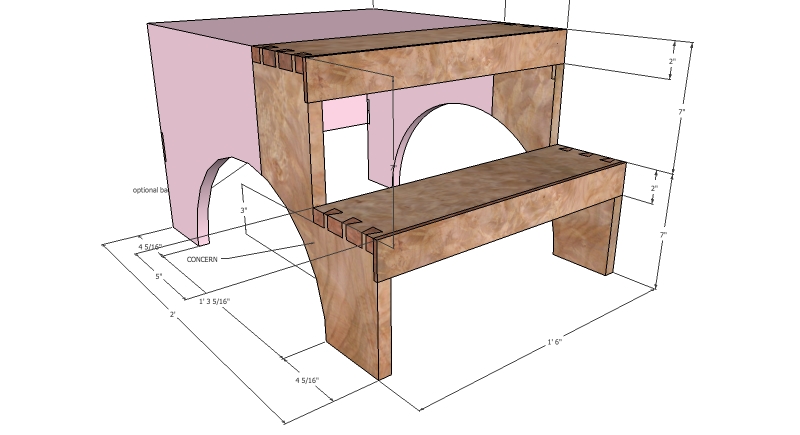

From the original questioner:

This is the front view of the stool. Joinery for the steps is dovetail. Front edge supports are glued in, with dowels if necessary. Below is an image for a traditional shaker stool that I used as reference.

Click here for higher quality, full size image

From contributor C:

I made one of these for a client as a good will gift after a large commission. They look and work well. Do an MDF mock up, if you are unsure of the exact dimensions use screws. If itís too big you can simply take it apart and cut a little off till you get something like what you want.