Straight-Line Ripping on a Bandmill or Table Saw

Techiques for resawing crowned boards straight. November 28, 2006

Question

What is the best way to get an accurate straight line on a board that has a bow from left to right? The equipment that I have is a bandmill, kiln and planer with dual re-saw attachment. Is there any way you can get an 8 inch board out of a 10 inch board with a bow and have it accurate?

Forum Responses

(Sawing and Drying Forum)

From contributor R:

I would suggest that you just put it on the bandmill to get a straight edge.

From contributor A:

I get a piece of melamine then clamp the bent board down and run it through the table saw. It produces a perfectly straight edge. However this does not work as well if the board is cupped and twisted as well as bowed. It’s not any different then the old straight 2x6 and screw the bent board down and run through the saw trick.

From contributor J:

It depends: long boards, short boards, and thickness. And so I shall assume this, of which I'm sure will be clear as mud. If the board is long and can be set on bandmill, to remove the hump get a visual, use the chalk line and snap a straight line - from low end to low end. Set it on the bandmill with both ends or ears of the board setting on log bunks against a 4x4 cant. This gets a straight line and to ensure the ends of board are of equal width. Cut the hump, flip and give the ears a whack Take your slice, remove and joint one straight side. Skip plane then run through the dual resaw planer/molder.

I say skip plane as my planer/molder/resaw has a limited depth of cut. Or snap a line and use circular saw free hand or with a straight line jig. I prefer to remove the hump or top of the bow with the saw first. One could now make a pass on the tablesaw for a rough cut to width removing the ears. If there’s a very slight bow and short boards I use my jointer removing the ears first.

From contributor N:

It depends how bowed the lumber is. Use your circular saw with a sheet of plywood or something straight.

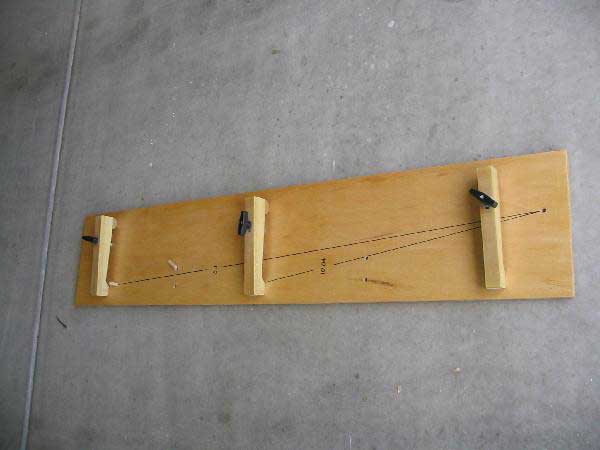

Click here for full size image

From contributor F:

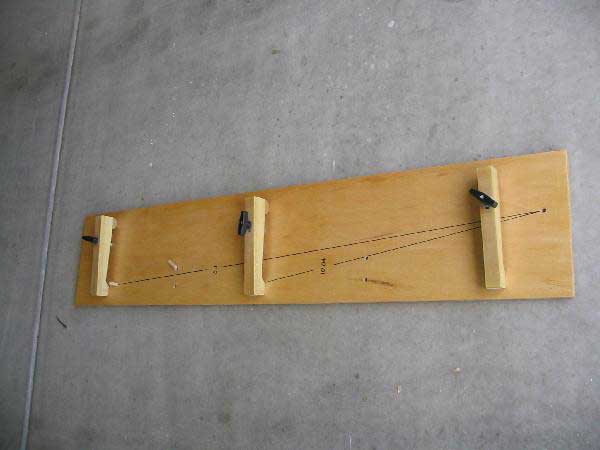

This straight line jig for a cabinet saw can be made in a length that you can handle. The jig needs to be very close in length to the longest boards you would straight line. The pictured jig is 68" and works well on up to 6' planks or boards. This jig can handle up to 9" wide boards but could be made wider. The jig is trimmed to provide zero clearance cutting. The bottom of the jig has a UHMW strip to fit the miter gage slot on my Unisaw.

Click here for full size image

"Photo by Fred Heenie".