Supporting Framework for a Built-In Concrete Countertop

Cabinetmakers share their structural intuition concerning a light built-in-place framework designed to support a concrete countertop.March 13, 2014

Question (WOODWEB Member) :

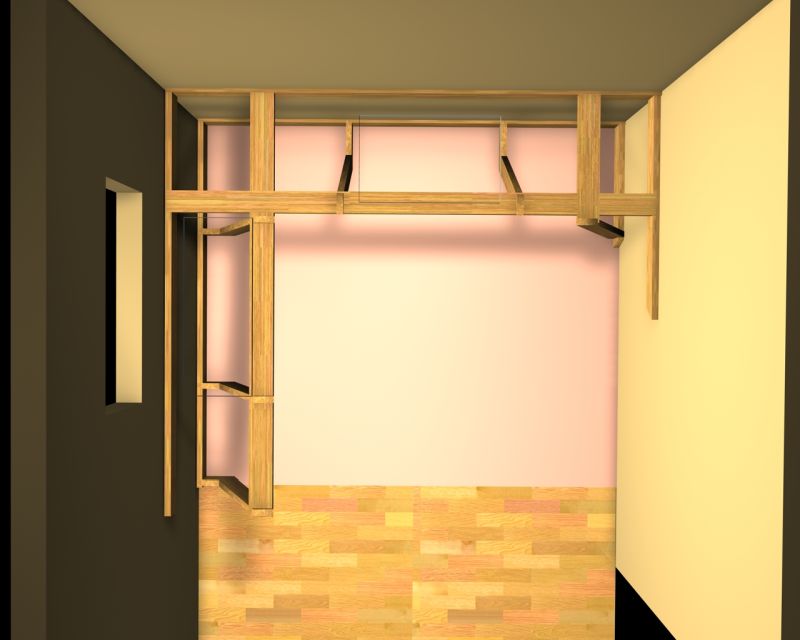

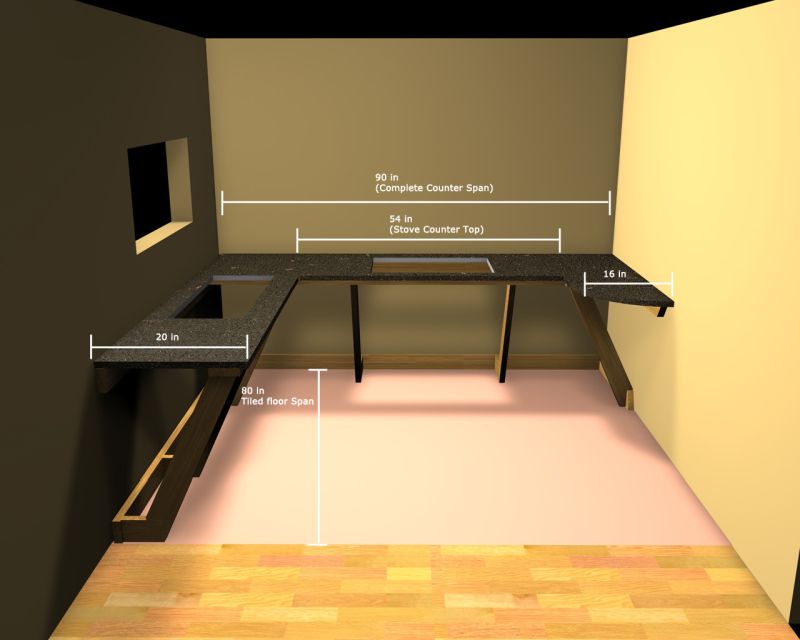

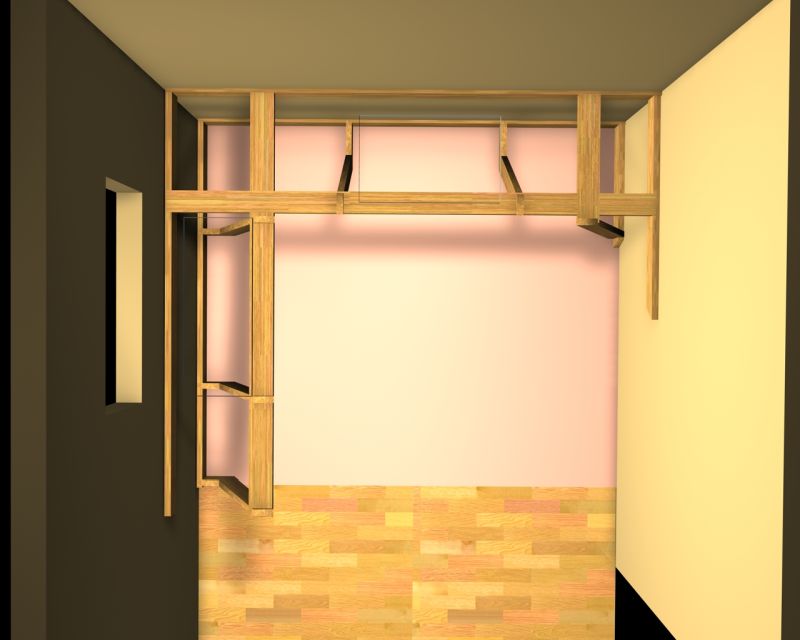

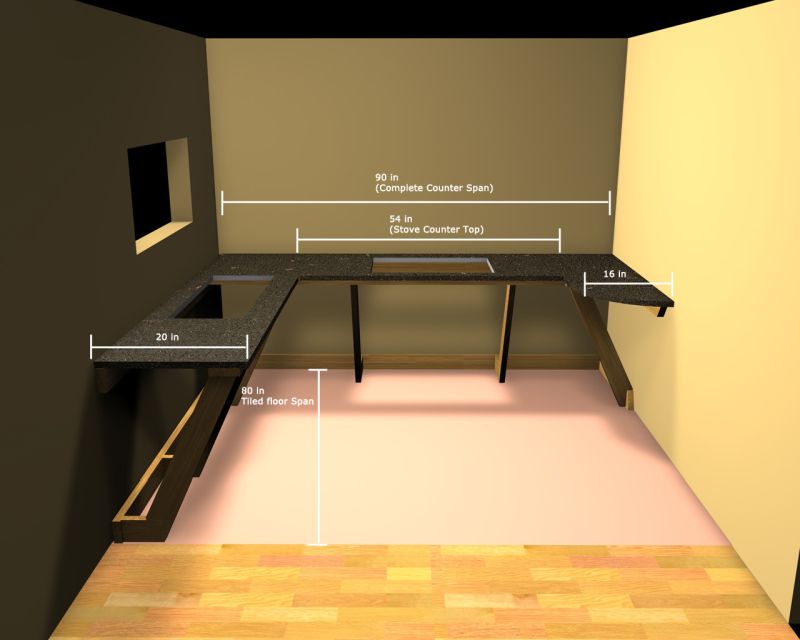

I'm a boxmaker and I'm making the bracing system below. Itís 1.75 x 4" hard maple as shown in this rendering for a 1.5" thick concrete countertop, with a small sink on the left and cooktop in back. My concern is whether trouble will result if I don't strip back the sheetrock where the top rear cleats attach to the wall, (maybe the bottom rear cleats too) and also whether I need to remove tile beneath the braces, or will this load be supported adequately without these precautions?

Click here for higher quality, full size image

Click here for higher quality, full size image

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor J:

Not what you asked, but I'd be more concerned about the absence of horizontal ties from the wall to the front/near edge of the countertop, especially at the end left of the sink. The weight of the countertop on those angled supports will make the countertop want to tilt inward, away from the walls. The ledgers along the wall have very little surface area on top so there's not a lot of room for glue there.

From contributor F:

I agree with Contributor J. I know that you are trying to keep the outside perimeter of the top clear for esthetic reasons, but completing the triangle/truss at both ends will provide a lot more strength; run a piece vertically, and tie the top stretcher back to the wall cleat. If your triangle/trusses are well-joined, the whole assembly has to pull away from the wall and tip forward. This means that the connection to the wall studs will provide strength. Lag bolts of the correct size, accurately positioned in the center of the studs will be strong enough, and you shouldn't have to rely on glue or drywall. In the end, no one is really going to notice the extra lumber at the ends of the counter.

From the original questioner:

That sounds like a good suggestion. I was planning on a horizontal piece at the sink counter end, but adding the vertical, making it a full triangular assembly, well joined. By doing this do you think Iím ok not stripping away the drywall, assuming I use something like 1/4 " lag bolts for the fasteners through the drywall into the studs? Is there a danger of the tiles cracking?

From contributor J:

I think that plan sounds fine. I assume you're talking about floor tiles. I don't think there's anything to worry about there, unless the tile installation itself is faulty. Our rendering makes it look like the concrete is fairly thin, and with the sink and cooktop cutouts you really aren't dealing with all that much weight.

From contributor R:

Based on your drawing and using Portland cement as an example you would have about 350lbs spread over the entire area. Unless you are going to pour it in place the already mentioned improvements it should be fine. I am not sure how it would hold up if someone (200lbs) sat or jumped up on it but the likelihood of that should be a fairly low risk.

From Contributor Z:

I agree that the thickness of the concrete top could be an issue and should be heavily reinforced or use a diamond mesh in lieu of welded wire fabric to ensure solid reinforcement in the concrete. It will also tend to crack at the narrowest sections near the sink and stovetop cutouts so the mesh should be one piece in these areas. The drywall should be fine provided the cleats are very tight and fastened at every stud. The tile is questionable as your supports are creating point loads to distribute the weight at those areas if there is a solid backer board, good thinset or mastic that creates a solid sandwich of tile and backer then this shouldn't be an issue, however if there is a ditra mat under the tile it could flex and crack the tile. If youíre not familiar with ditra mat itís an orange plastic mat with square raised sections that permit the subfloor to flex and not crack the tile under normal foot traffic. Keep in mind the load created are dead loads so if the tile does not crack once the top is installed then you should be ok provided nobody places a larger load on top of the counter or an impact load such as dropping or jumping on the counter.

From contributor S:

You'd be better off having your triangle supports meet the bottom of the walls a few inches above the floor rather than land on the floor. The way you have it pictured you're creating a nightmare as far as floor cleaning goes. You don't have to strip the drywall to mount your top cleats to the studs. Just put some glue on the back of the cleats when you mount them.