Tool Diameter Measurement Precision

What tolerances are involved in mating a shaft to a cutting tool? January 12, 2015

Question

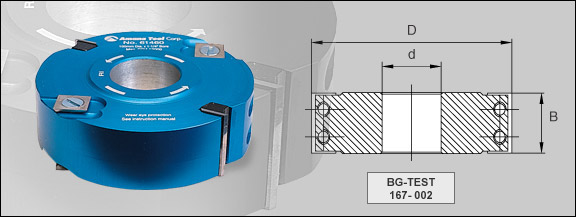

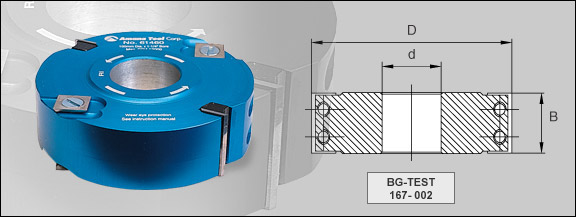

I'm having an arbor made to fit the type of rabbeting cutter shown in the attached photo. When the tool is labeled as having a 1.1/4" bore does that mean that a tool holder/arbor needs to be slightly less than 1.1/4" diameter to fit tightly as opposed to not fitting at all? If I had the arbor made with a 1.1/4" diameter would it fit? Obviously I want to choose a diameter that would be the perfect fit. The tool I'm talking about is a AMANA 61460 100x30mm insert rabbeting cutter.

Click here for higher quality, full size image

Forum Responses

(CNC Forum)

From Contributor D:

I measured a 1.25" arbor I have and it is 1.2492, so less than one thousandths undersize. I measured a couple of shaper cutters and they seem to be .0005 to .001 oversize.

From Contributor H:

You have to have a least a .001 tolerance somewhere, most of the time it is on the cutter. If you make it too tight of a fit and you get some heat in the cutter, you may not be able to get it off.

From contributor R:

I'd be nervous about having a custom arbor made. Who chose the steel alloy and the heat treat? Shapers scare me more than any machine in the shop for some reason, and a machine shop made arbor won't give me more confidence. Maybe you are using a shop that does this all the time, then no worry. I'd wait till the tooling is in your hands before they design the fit.

From contributor S:

Tolerance on your arbor should be +.0000" -.0002" or basically right on size. Most tooling manufacturers will make the bore of the cutter slightly larger, I can't speak for anyone else but our tolerance would be +.002/-.000 for 1.250" straight bore.

From contributor V:

Arbors are available off the shelf for ISO or HSK spindles in 1-1/4" and 40mm shafts, I use them all the time for shaper heads. If you're planing on making an arbor to go into a collet to spin that tool i would not consider that a wise idea.