Tooth setter

Other Versions

Spanish

Photos and descriptions of home-built tooth setters for band blades. March 5, 2003

Question

I know some of you have made your own tooth setters for your band blades. Can anybody help me with pictures, plans, drawings, specs?

Forum Responses

(From WOODWEB's Sawing and Drying Forum)

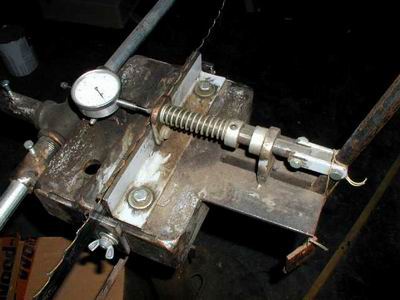

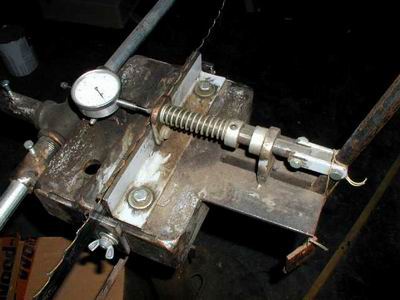

I just made my setter from a picture of one in a magazine about 8 years ago. I think it is better than most commercial ones I have seen, though. The thumb screws on the side control the height of blade so I can set anything from 3/4" up to 1 1/2". It can also be adjusted for different thickness of bands. I got the dial indicator from Enco. It was an import model, not very expensive and has done a good job. The ram that bends the tooth is curved a little to push the tooth over. The emt pipe on the back is just to hold the band up so it doesn't flop around. I put the setter on a 3" pipe that I welded to an old round tractor wheel weight. It works as good as the commercial models and the only expense was the dial indicator.

How long to set a band (1"pitch x 19'L)? Do you position the teeth to the setting ram by hand? Could a ratcheting advance leaver/pusher be added that might be faster and more accurate? I am thinking seriously of building something just like pictured above. Any detailed help would be greatly appreciated. I have the dial indicator already.

I made one with ratcheting action and it does speed up a lot. Every time you move the lever, it goes forward three steps right on the next time to be setted.

My philosophy on sharpening is this... I'm in the lumber cutting business. Buy a good auto sharpener, dual tooth setter. I don't worry about dull blades, sharpening cost, shipping. I can run blades with an overall average of much sharper (more profit). Sharpening/setting time is minimal (time is money) and blade after blade the inefficiency/time difference adds up. If you have good quality sharpening equipment, you also have the option of sharpening blades for a few customers. This diversifies your business and generates income.