Troubleshooting Mixing Issues with an AAA Pump

A finisher tries to figure out why his CAT 2k pump is producing streaky results from the gun. July 29, 2014

Question (WOODWEB Member) :

Several months ago I purchased a 2k pump by CAT (Catalyzer is their name) and have been having problems with how it mixes the two products together - catalyst and base/lacquer. Just wondering who else has this pump, and what your experience has been with it. I have been working with CAT to resolve the issue, and they have been helpful, but after two months of replacing parts and cleaning pump internals, the problem remains. Basically the pump appears to spray random streaks (like a dirty/defective tip), but only when catalyst side is on. Currently we have to hot pot the finish and spray through base side only and have excellent results. Below is what the paint looks like with the air off, and reduced to manufacturer’s spec.

Click here for higher quality, full size image

Click here for higher quality, full size image

Forum Responses

(Finishing Forum)

From Contributor B:

It appears that the spray pattern on the un-catalzyed product appears to be decent, do you agree? I think it's related to the coating, not the pump. Is it possible that you have used the wrong catalyst, or the wrong amount? Did you thin the material before catalyzing? Some manufacturers recommend thinning after catalyzing. Is the material/catalyst/thinner cold? Most coatings will not flow well unless they are above 65 degrees F and do not tolerate cold thinners (makes them stringy).

From the original questioner:

Where we are at now with CAT is they want me to ship the complete pump back to them (at my cost), from Canada for them to check out. I have had the catalyst pump and quad valve apart and cleaned thoroughly (with ultrasonic cleaner). Currently I am using the pump to pump off and catalyze material into a pail, manually agitate it, then pump pack through using just base side (catalyst is recirculating back to holding tank).

I have used several products regarding 2K, including Chemcraft's Plastifix and Danspeed sealers, their post-cat colour PlastiColour I think, as well as Becker Acroma's Amerivar. The streaking is less apparent when the base is reduced to spray consistency (15% - approximately 30 sec Ford 4), worse when spraying right from pail unreduced. All paints/catalysts exhibit the streaking issue.

Once catalyzed through pump and manually agitated it sprays excellent using just the base pump. I have tested all the valve seats using their methods and with their techs over the phone, both pumps stall correctly on the up and down strokes. I have removed and cleaned the mix element (which is integrated into quad valve), even replaced with a new one (at my cost). To me this problem really seems to be a mixing issue and possibly a problem with the design of internal mix chamber/element. I am considering purchasing an external static mixer and using that as pump appears to be dosing catalyst correctly. I should also mention that I purchased a second fluid hose to try out but made no difference (first one had some paint buildup in it and was releasing debris).

Click here for higher quality, full size image

From contributor C:

I am spraying a 2K urethane from Ilva through a Graco promix system. One thing I have to watch for is that the catalyst attracts water and crystallizes. I had to get a moisture proof pump for it. I was not able to use a basicAAA pump but had to shell out about $4000 for a specific pump. Could it be that your catalyst is doing the same?

From Contributor B:

I think your trouble is isolated to the quad valve. From what I understand you can bypass this valve and it appears to work fine, but when you use the valve your coating pressure appears to drop to a point where you aren't getting a good pattern. Your coatings are not your problem, so let's focus on the equipment. Since I think it's a pressure related issue, the fluid hose you replaced was it the same diameter as the factory hose? I'd think that you could increase your fluid pressure and eliminate this problem, but it may not be that simple. Can you place a pressure gauge after the valve and before the fluid hose? You need to get a pressure reading from using the valve and bypassing the valve. I'll bet there is a difference. If there is no difference, you might try using a smaller diameter fluid hose to increase your fluid pressure to the gun.

From the original questioner:

The post-cat lacquer's catalyst doesn't appear to have ever crystallized not sure if that is something specific to urethane perhaps? The fluid hose is 1/8" but I did purchase a larger 3/16" hose thinking it would be easier for the pump to push thicker, unreduced product right from the pail (just switched from a pressure pot). I haven't installed the 3/16" hose, but you are saying that the larger hose would have the opposite effect and actually cause more pressure drop to tip?

Couple of other observations:

1. Normally if the pressure drops the fan width is affected - narrows, width is the same. Also, have tried this at higher pressures - normally 500 but have gone up to 1000 even at reduced viscosity and that helps a bit, but doesn't resolve the streaks.

2. When the product is sprayed with base lever down and catalyst up (recirculated) the pattern is fine, but when I flip down the catalyst lever (adding it to mix), the pattern remains fine for 5-10 seconds until the catalyst arrives at the gun and then it starts streaking again. The spray width remains same. I have tried different width tips (same .013" orifice) with similar results.

3. When spraying regularly (catalyze on the fly) the internal pressure guard does not activate unless there is a pressure drop on either side (run out of either product/air bubbles). This has been working fine. (I am still using the pump on the 2K mix just not on the final coats - hot pot those ones and use the base side only). Could this be inadequate mixing? Perhaps the internal static mixer is not sufficient and a second external one would ensure complete product mix?

I was unable to get any referrals from CAT for others who have and use this pump, and very little info online by way of reviews (wasted a couple weeks waiting for them to deliver promised contacts). I did talk to one company in Ontario that uses theirs only for clear only and they said it seemed to work ok. So I'm not sure if I have a lemon or it is just not designed correctly.

From Contributor B:

If I remember correctly the larger the hose the more pressure it takes to reach the desired effect. From what you said in your last post - "the pattern remains fine for 5-10 seconds until catalyst arrives at gun then it starts streaking again" - this means that when you are just spraying paint, no catalyst, the pump appears to perform fine, but when you add the catalyst the pattern goes crazy. This to me indicates an issue within the valve body itself, possibly causing a drop in fluid pressure that you can't really see unless you have a fluid pressure gauge mounted where the fluid hose would ordinarily be connected to the valve body. The gauge is not cheap (CAT should send you one for testing) but should give you a firm idea of if you are having a pressure issue or not. The stall test doesn't always give you definitive information, it just tells you if the pump can hold pressure, which it can if you don't pull the trigger.

From the original questioner:

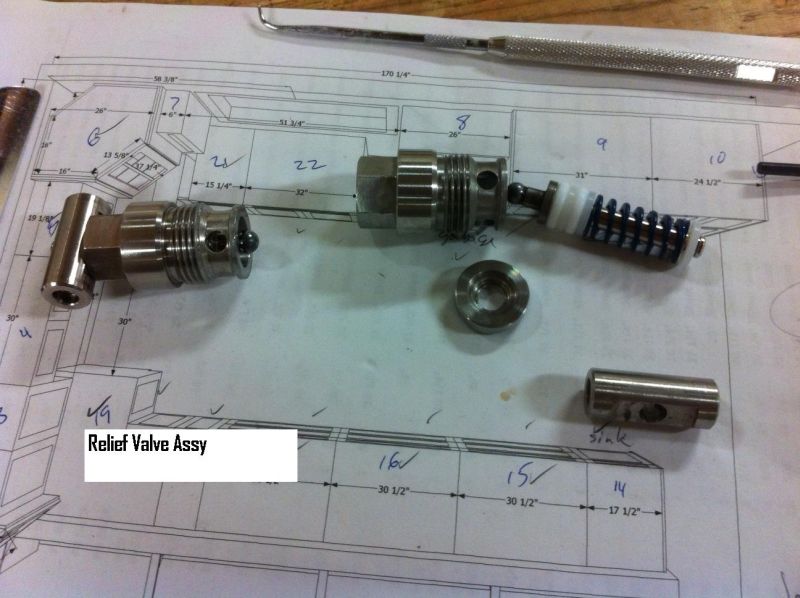

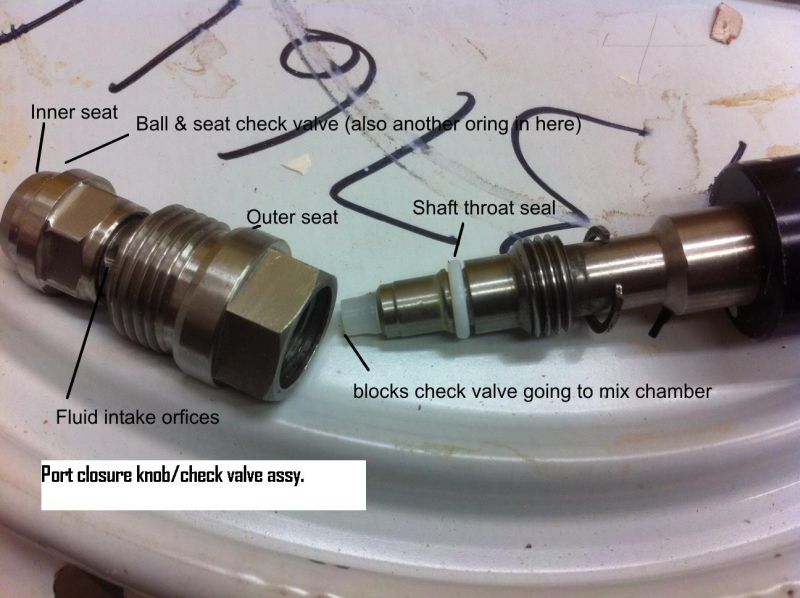

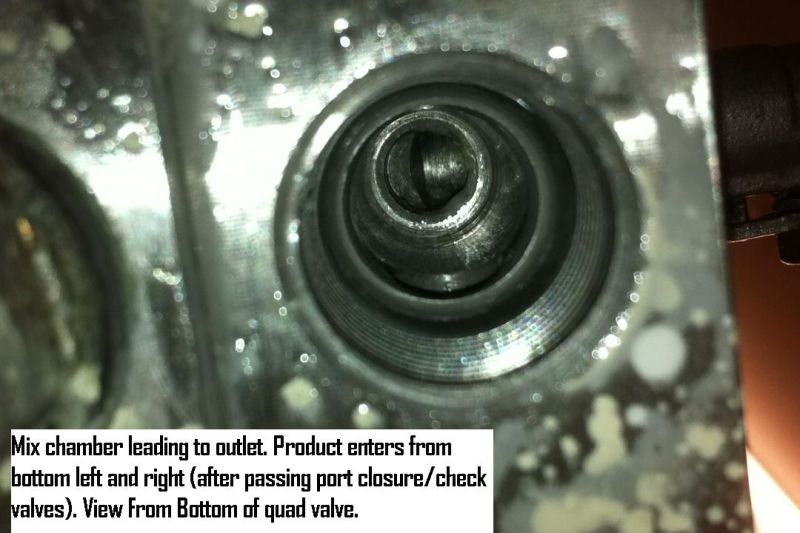

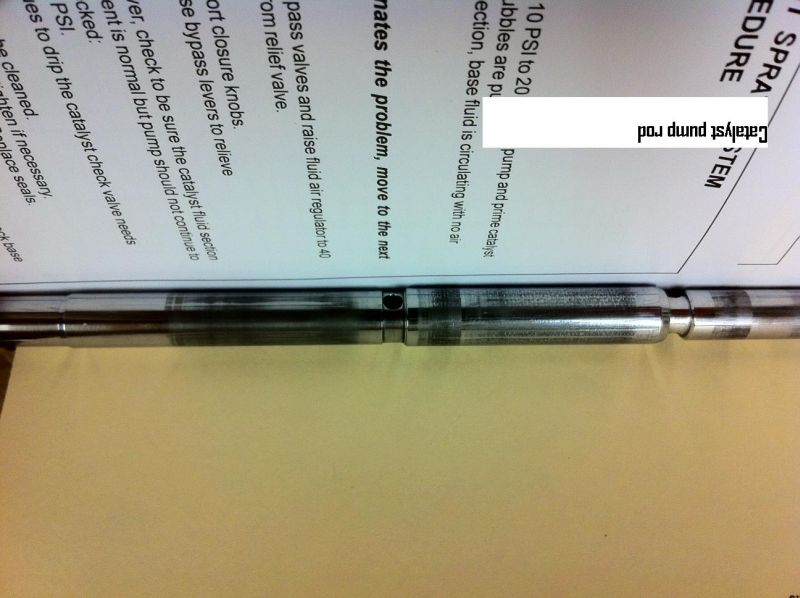

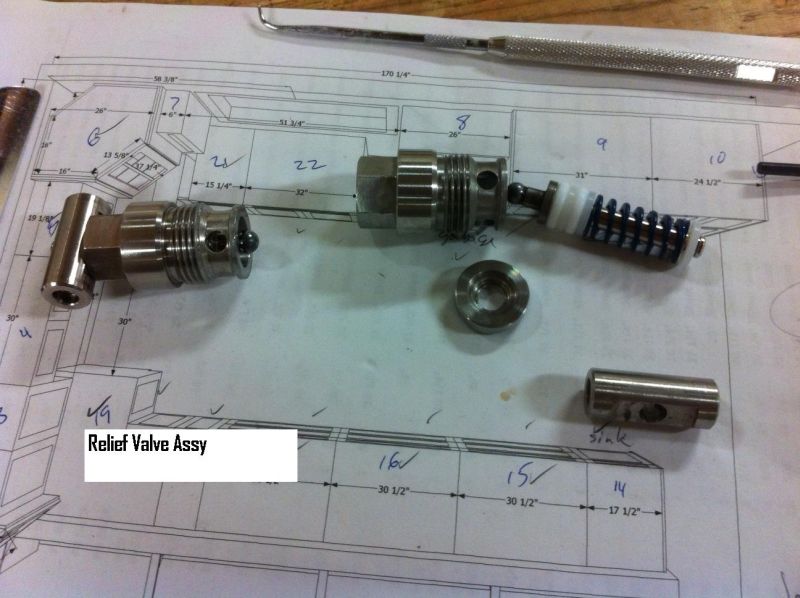

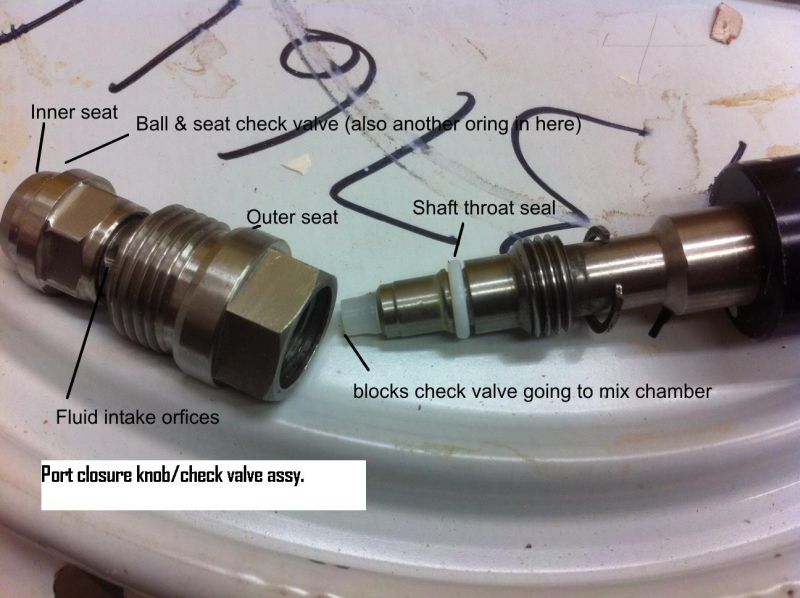

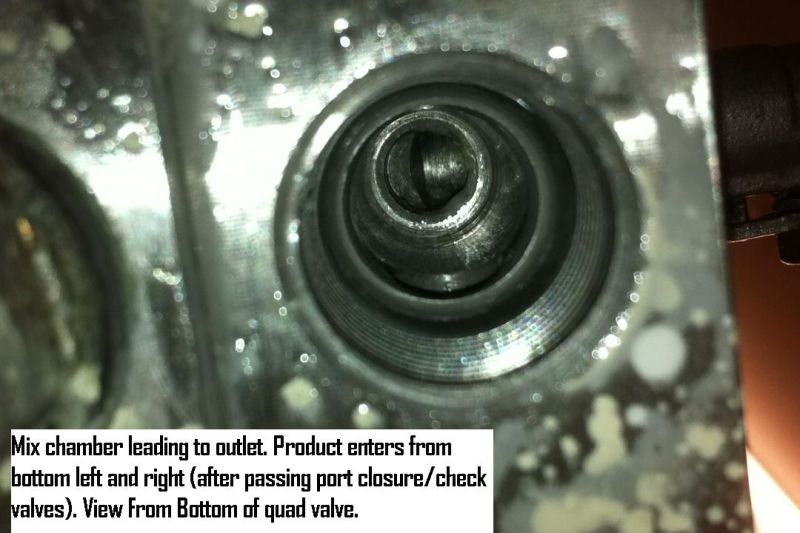

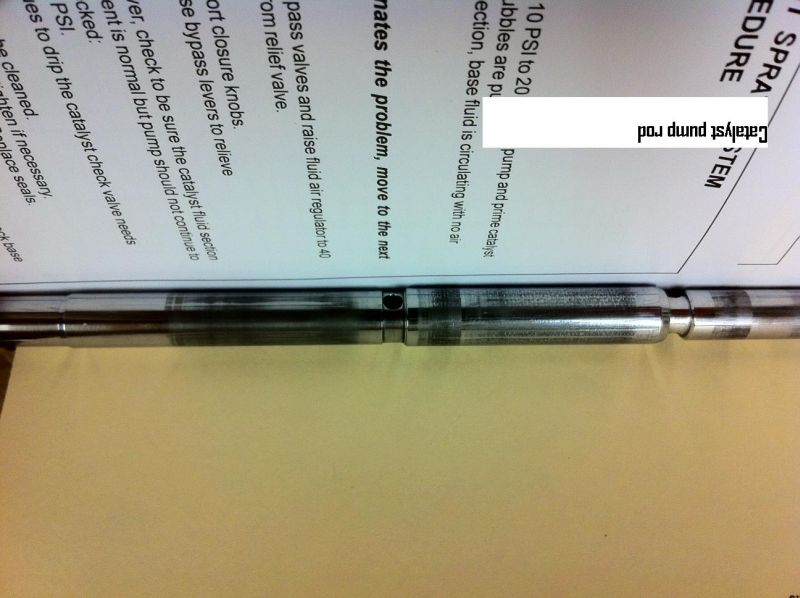

To contributor B: Are you suggesting a problem with pump pressure, as it enters the quad valve assembly? Or a problem in the check valves? I have included some of the pics I took when I disassembled and cleaned the fluid section of the quad valve. Also, the pump rod appears to be discolored but C.A.Tech assures me this is fine. I did not disassemble the rod, but I guess there is some specific setting it has to be tested for when assembled (there is an internal ball that rattles). I don't have access to a fluid pressure gauge, but do you have any other suggestions for me to inspect or test?

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

From Contributor B:

I think that your pressure is dropping when you activate the catalyst side of the Quad Valve. It's like the valve itself is allowing fluid to leak somewhere, or there is a restriction. It may be a manufacturing defect in the valve body itself. I'd ask CAT to send a new valve and see what that does.

From contributor U:

The products you are attempting to spray (and have the unit catalyze), do they call for the 10:1 product to catalyst ratio? Or is your unit calibrated to catalyze at a different ratio?

From the original questioner:

Yes the Chemcraft products are 10:1, but Becker Acroma's are 12:1. I have to reduce base for the additional 2%. Either way, when reducing base catalyst also has to be reduced by same percentage - once you get them to a 10:1 spray ratio anyway.

From contributor M:

I know this doesn't help you now but I had the same problem spraying pigmented CV when I had the CATalyzer in for a demo. The reason I can't help is we didn't end up buying it because of this and other issues we had. The only thing I can say is you are not the only one who has experienced this problem. The system we went with requires the catalyst to be sprayed at 10-15% higher fluid pressure to force it into the mixture preventing the base side from overpowering and pushing the catalyst back into the wrong direction. I wonder if this collision of materials is reducing your pressure after the mixing occurs. It could be verified using the method of a pressure valve after the mixing is done as stated above in another post.

From the original questioner:

The unit we purchased was from CAT's Canadian distributor and was actually their demo unit. So yes probably sending back to them will be the best bet, assuming it is defective and doesn't get returned with same issue. I am trying to determine if it is a defect or design flaw (no point sending back if this is how it is designed and even a new pump does this). My assumption now is that the pump does not completely mix the catalyst and base, and I may have to purchase a secondary mixer to go inline with the paint hose (probably an additional $200). As for shipping my costs will approach $450 including brokerage fees. I should note that this problem exists for pigments and clears alike (although less apparent on clears, and with enough atomizing air it is marginally usable).