Troubleshooting the End Trimmer on an Edgebander

Tips for adjusting an edgebander for accurate trimming of the banding material. February 17, 2014

Question

WOODWEB Member:

I am having trouble with the lead trimmer on my machine. It seems the PVC material is curling up, causing my trimmer to fold the edge rather than trimming the excess off.

Forum Responses

(Laminate and Solid Surface Forum)

From contributor J:

For whatever reason you most likely have too much material being left at the lead edge of your panel. When the banding is cut from the roll after a piece is run, does the machine pull the tape back to a set position to receive the next panel?

On our bander there is a relay that we can adjust to leave the leading edge amount of overhang less or more. Usually there is about 1/2'' to 5/8'' of overhang, when a new roll is put in and the operator pushes the band in too far, we get the same thing on the first piece. But after that the bander pulls the tape to the correct location.

From the original questioner:

Thanks! That is what I figured out as well after I wrote that message. My manual doesn't give me any information on how to adjust that distance. As of right now, the tape on the lead edge is well over 5/8. I guess I will have to talk to my rep to see where I can get a book to show where all these adjustments need to be made.

From contributor P:

End trim systems work by having a shoe contact the edge before the saw comes into the cut area. If the too-long edging does not cure the problem, you may want to look at the timing of the shoe against the panel edge before the saw comes in. If the shoe has not yet arrived to the panel edge when the saw comes in, then you are folding the excess over with the side of the blade rather than trimming it off. The solution would be to increase the air pressure slightly so the shoe gets to the edge faster.

From contributor H:

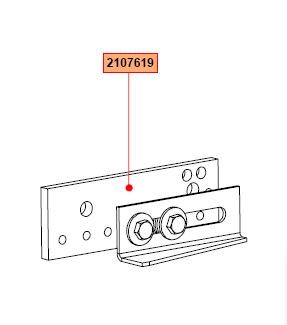

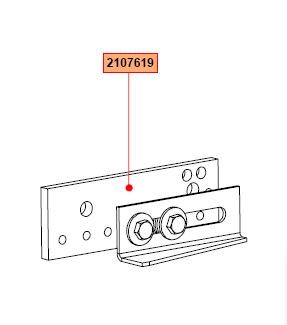

You need to adjust the tape guide mounted along the pressure hold-down beam, near the front end trim trace shoe.