Understanding "Blind Dado" Cabinet Construction

These illustrations and explanations help to visualize how blind dado details work to hold cabinets together. July 29, 2007

Question

Could someone please explain blind dado construction for face frame cabinet construction?

Forum Responses

(CNC Forum)

From contributor R:

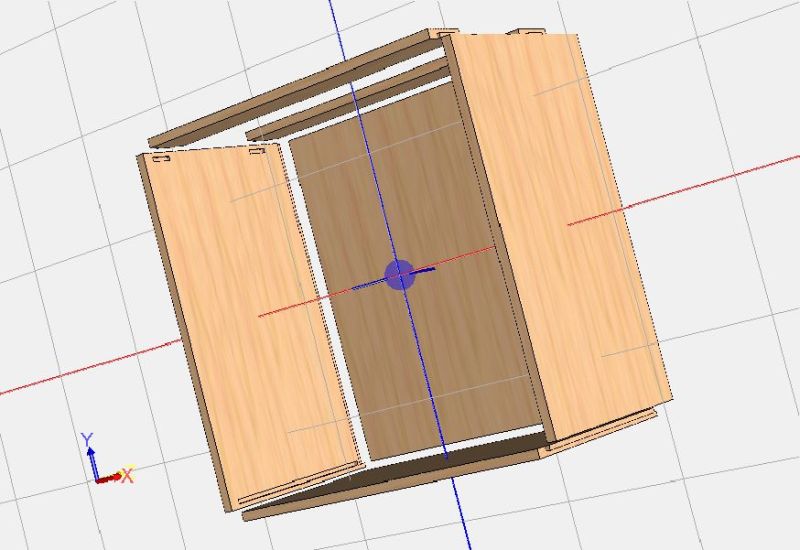

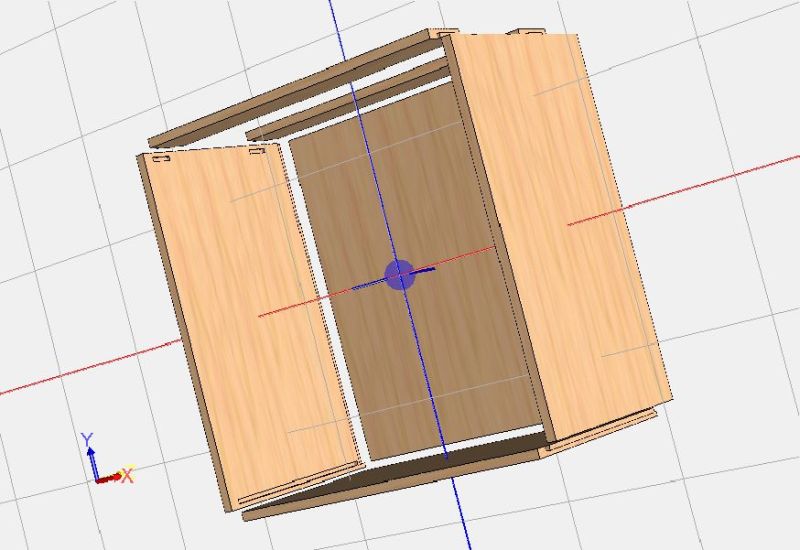

Blind dado is a box style whether using face frames or not. If you look closely at the drawing you see that the dado is stopped before the panel edge and is half the width of the material. Usually used with CNC production or sometimes vertical panel routers. Very strong and easy to assemble.

Click here for higher quality, full size image

From the original questioner:

Thank you. How are you attaching the box to the frame? I currently pocket screw.

From contributor T:

I have read all the numerous posts on blind dado construction and since this is the first time anyone has posted a visual, I have a key question. How is the back held in? We currently use confirmats and we fully house all the edges of our 3/4" backs which really helps hold the case square. With the method shown above, how do you house the back edge on the bottom and the top rail? If I machine the blind tongue as shown, I will have to be flipping the part to machine the dado for the bottom/top rail. I understand the parts should be ready to assemble and it has been stated that the parts will hold themselves together, but how?

From contributor R:

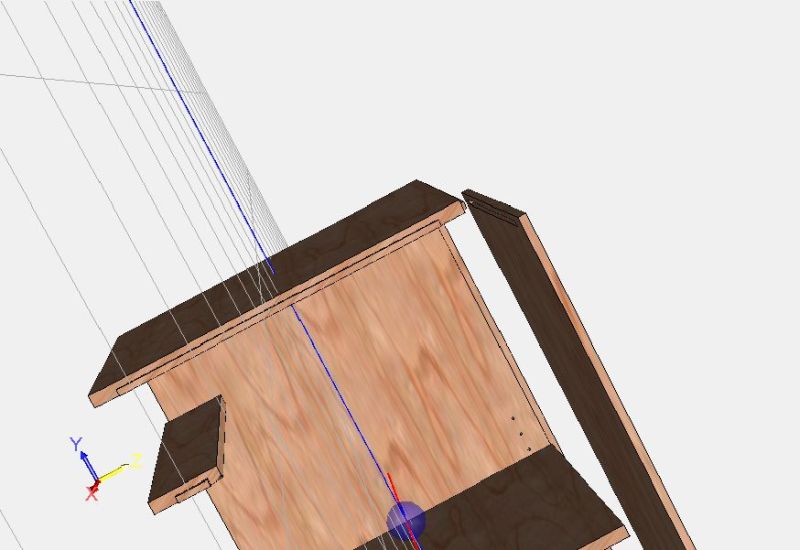

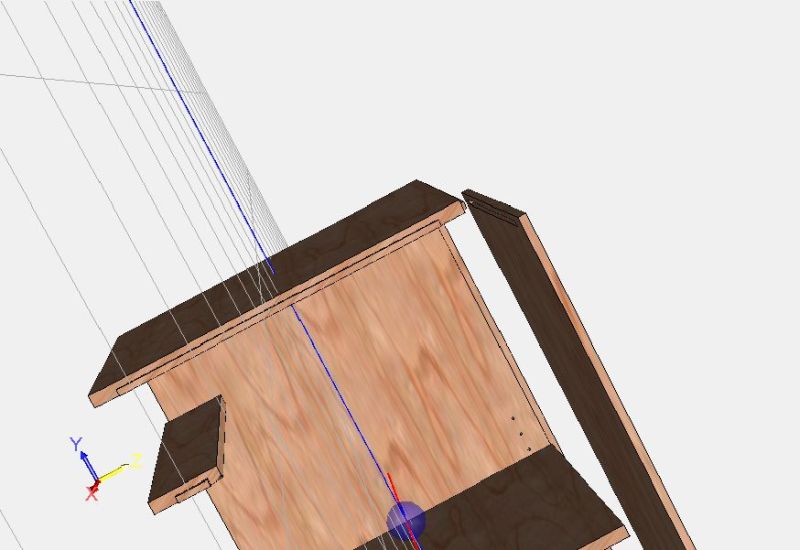

In this sample I use blind dado top and bottom with full along the sides. Often times I use a full dado with 1/2" back 3/4" inset (the back is fully captured). The only way to avoid flip ops is to designate material "A side up" or "A side down" and then run your batches accordingly.

Click here for higher quality, full size image

From contributor A:

You can capture the back in a groove on the sides and then nail it as a plant-on back for the bottom and top.