Hi Guys,

I've been asked to price out a job where I'd be providing kitchen cabinet doors made from Corian.

Obviously, the weight is a major concern. None of the doors are overly wide and I'd have the latitude to alter the layout if need be.

I was thinking I could just go for 1/2" material and leave it at that but I'd rather shoot for 3/4". I was considering using the CNC and hogging out 1/2" from the back of the doors, leaving a 1" border around the perimeter. I'd also leave a few "islands" of material where the cut would only be 1/4" deep. Then I'd fill in the cut out back with a piece of 1/4" Corian. This would give me a "hollow" 3/4" door. This technique would help with the drawer fronts as well, except I'd just use 1/2" plywood as an insert, which would be used to attach the drawer front to the drawer.

Any advice is welcome, but I'd really love to hear from someone who has actually done this before. BTW, the client has pretty deep pockets, so I'm not overly concerned with the time/labor involved. I just want to deliver the most weight efficient product I can that also looks great.

Thanks in advance!

From contributor mi

guess you could use 1/4" material and build up edge using 1/4 or 1/2 material.

From contributor Ri

Heavy!!! what kind of hinges are you using...if a blum or eq. you will need more than a 1" border . I would like a customer who could afford solid surface doors!

From contributor Je

No experience, but I think Mike's idea is on the money. Make the core up with mdf and glue skins and edging to it. Should be considerably lighter than solid Corian.

good luck,

JeffD

From contributor JJ

Michael, I just did a cabinet using 1/2" Corian and I am familiar with the techniques used in this application. I've only seen this used in a few high-end European lines that I've researched. Each has a somewhat different approach although the process you described is not one of them. Along with technique there are things to consider with each such as brands (Corian's patent has run out so there are alternatives) sizes per brand, substrates, weight, hinging and surface treatment.

From contributor De

We are seeing solid surface material specified for cabinet doors and entire casework, particularly in hospital and laboratory environments. Solid phenolics are also being specified.

You are correct in being concerned with the weight of the material. For this reason, it is a very common practice to use ½” material for the doors.

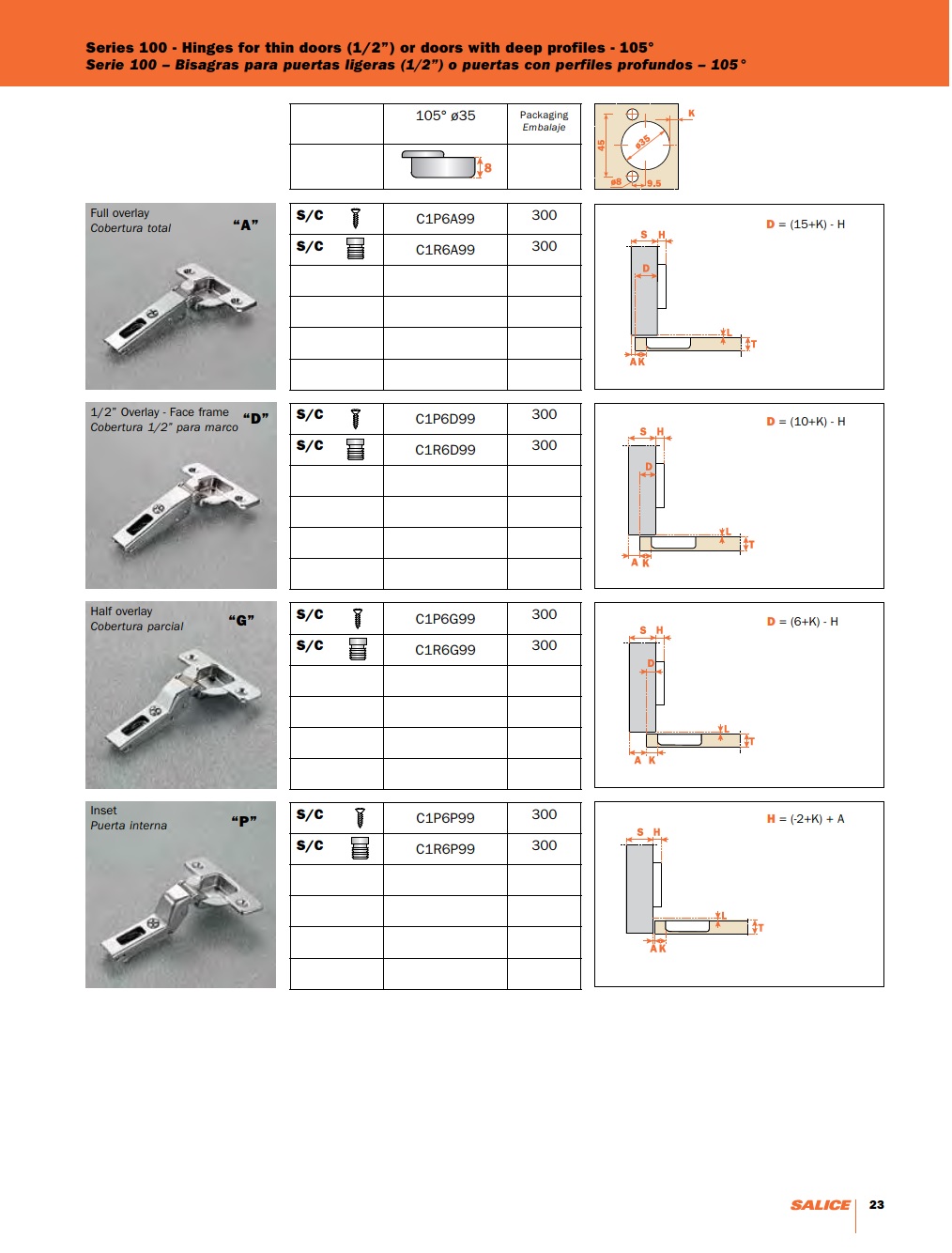

This can be problematic when choosing a hinge for the job. Since most European, concealed hinges require a cup depth between 11mm and 13mm they cannot be installed in 1/2 “ material.

The Salice, Series 100 hinge system is an ideal solution for this application. Since the hinge cup needs only an 8mm boring depth it is perfect for ½” door applications.

Here are some of the details. If you need additional specs or samples for prototyping, please contact me or your local Salice distributor.

From contributor JJ

I looked at the Salice and Grass hinge shallow cup hinge but they did not have built-in soft close. There is a way to do it with Blum integrated soft close hinges. Like I said several European cabinet lines use solid surface material and each has a different approach.

From contributor De

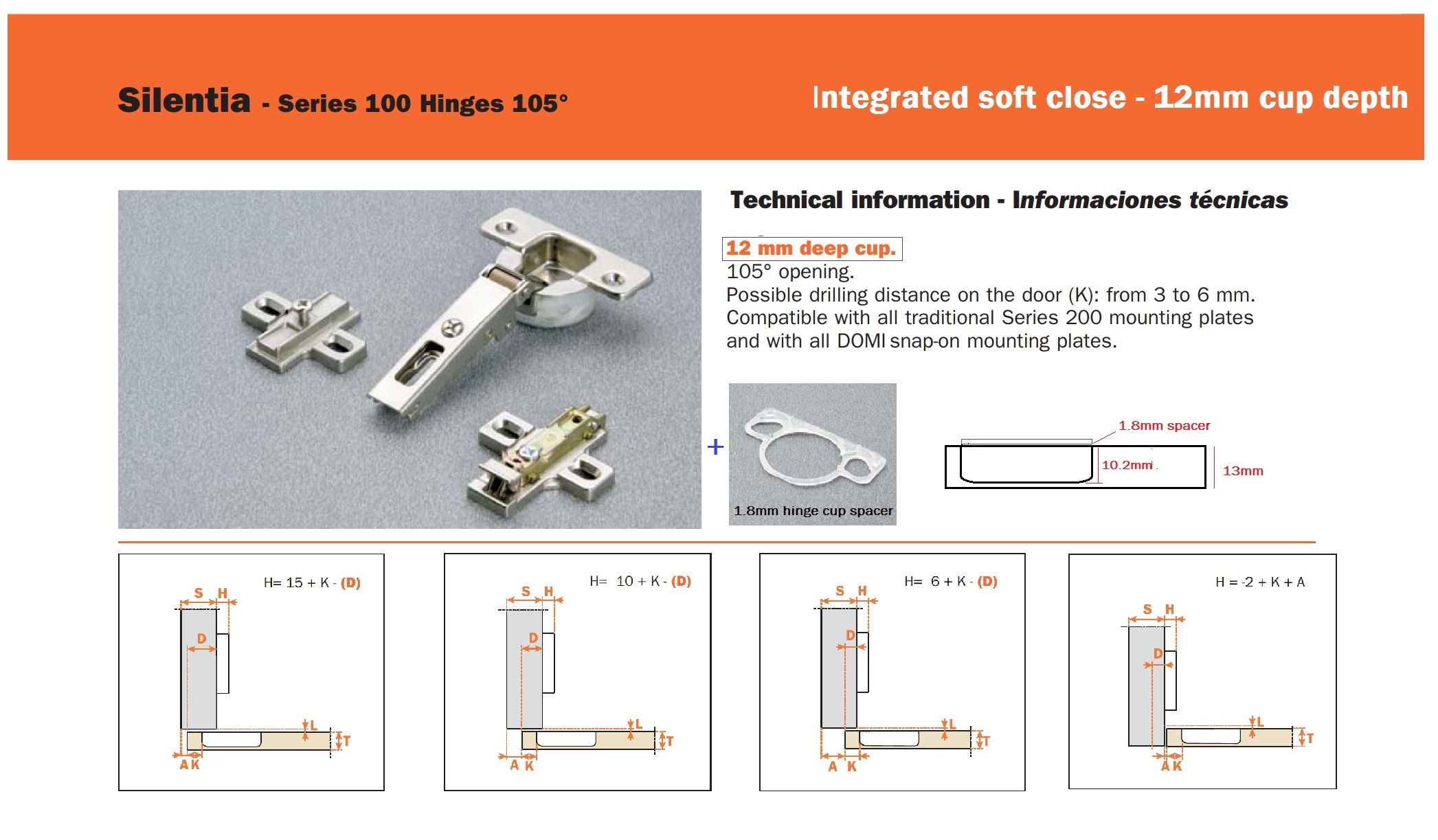

The Salice Series 100 soft close hinge features a 12mm cup depth. In 13mm thick material it would be possible to drill the cup depth at 10.2mm (or a little more), add a 1.8mm spacer and install the integrated soft close Silentia hinge.

I would however suggest a trial be made to insure the hinge cup boring outline does not telegraph through to the face of the Corian door. You may also find it necessary to grind off the center point on the 35mm bit to insure it does not bore through the face of the door.

Soft close is within the realm of possibilities for this application with Salice.

From contributor ma

I've made cabinets, inc. doors from 1" 3-Form: really heavy stuff. I used grass hardware, but this was before integrated soft-close. This had to be translucent, so no build-up was possible, but for corian, I'd be tempted to consider 1/8" skins/edges with a structural foam core. Lots of work for sure, but the product would be much more resilient than solid corian. The stuff is brittle.

From contributor Ha

We have used the squirrel fixing ,super job ,

attached link http://www.squirrels-uk.com/corian_doors.htm

hope this helps harold

From contributor St

I've ordered wood cabinet doors here: https://www.cabinetdoordepot.com/kitchen_cabinet_refacing_204cms.htm

They are perfect quality and you can do them yourself