Reprinted with permission from Tom Galzin of NewCNC.com Inc.

An explanation of flow and pressure for vacuum pumps

I have used vortex, regen blowers (both single and two stage), roots type blowers, claw blowers, liquid ring, oil less rotary vane, oiled rotary vane, rotary screw and piston style vacuum pumps, also combinations of roots blowers and rotary vanes during my 25+ year tenure of vacuum fixturing in the CNC Router business.

I believe that an understanding of pumps is needed to make an informed decision as an owner of a CNC Machine. And together with understanding the level of vacuum generated by a particular pump, the size and flow must be part of the decision on what size (HP) to select.

The flow of a vacuum pump and the ultimate pressure of the pump have a NEARLY linear relationship. By that I mean more flow per HP means less pressure, and conversely more pressure per HP means less flow. Different pump manufacturers can claim a larger flow at a certain pressure than others, but the difference in efficiency of the pumps from one to another is measured in single digit percentages (~2 - 4%). All graphs showing the flow and pressure of a pump will show the greatest flow at the least pressure and the least flow that the greatest pressure. (Beyond the maximum pressure of the pump, flow drops to near zero.)

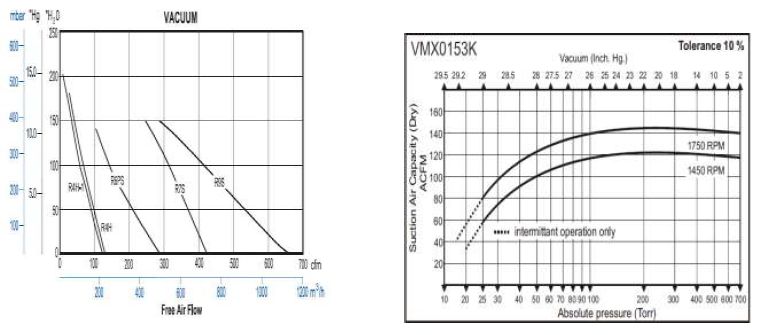

I’ve attached two flow curves. On the left is a regenerative blower, where the flow is the bottom scale and the pressure is the vertical scale. A 10 hp machine is represented by the “R7S” curve. The second curve for a liquid ring has the scales reversed, flow is vertical and pressure is the top vertical scale.

So as a “rule of thumb”, NOT SPECIFICALLY, a 10 HP regenerative blower running without restriction will move about 420cfm as has a max pressure of about 10”Hg. And a 10 HP liquid ring running without restriction, will move about 150acfm (acfm is Actual Cubic Feet per Minute) with a max pressure about 29”Hg. So again as a “rule of thumb” and within about a +/- 2% range, you can say a regen blower has 3x the flow but 1/3 the pressure of a liquid ring per HP. Conversely you can say that a liquid ring has 3x the pressure but 1/3 the flow of a regenerative blower.

Cost, of course, needs to be a part of the decision. Generally speaking, (and a vortex generator is the exception here), the deeper the vacuum generated, the more costly the pump.

Further I believe that once there is an understanding of pump types and the relative flows per HP, there are three more areas that need to be understood before a vacuum pump type and size is properly fitted to the owners’ requirements. Specific applications are discussed in part 3.

Reprinted with permission from Tom Galzin of NewCNC.com Inc.

Vacuum Fixturing - Part 1

To receive part 3 of this series, contact Tom directly: