Where Doors and Panels Meet

How various cabinetmakers deal with the relationsihp between overlay doors and the adjacent edges of finished end panels. January 24, 2005

I have a question for those that use applied ends with frameless construction in cabinets: how much door overlay do you use?

With 3/4" cabinets and a 3/4" applied end, you would need almost 1 1/2" of overlay to cover both the cabinet end and the edge of the applied end. This seems to be impossible with clip top Blum hinges. I probably can do this using Compact 33 hinges and a face frame plate such as 130.1150.02, but this would also space the door 3/16" away from the front of the cabinet.

From contributor A:

I don't change the overlay of the cabinet door. The applied end is 10-20 mm deeper than the cabinet side, covering the edge of the door.

From the original questioner:

Perhaps I am looking at it all wrong. Instead of trying to cover the edge of the applied panel, I should be covering the edge of the door with the applied panel. Is this how others are handling applied ends or are there methods that I have not considered?

From contributor P:

I don't build frameless, so there may be a reason this can't be done, but rather than applying a panel on top of an end panel, why can't you make your applied panel serve as the end panel?

From the original questioner:

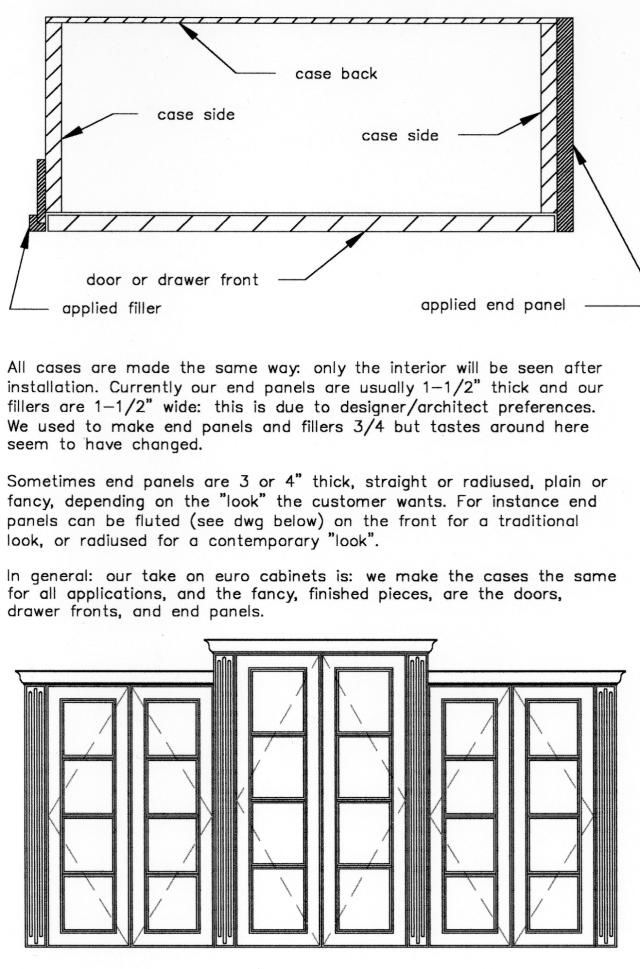

One of the primary reasons for the applied end panel is to hide the construction of the cabinet. In other words, the end panel covers the screws holding the cabinet together.

Of course, there are construction methods that your suggestion would work with, such as dowels and pocket screws, but that becomes a whole new discussion.

From contributor B:

In frameless cabinets, there is no overlay for applied ends. If the depth of the cabinet is 600mm, then the applied end is also 600mm.

From contributor J:

We have gone through this for years. First, in response to whether the end should overhang the door or vice versa, it depends on the look of the unit. If you have 3/4" reveals or if you have pocket doors where the 3/4" edge of the cabinet sticks out, then the panel overhanging the door would look fine, but that is really the only case. As far as the overhang of 1 1/2", we have tried every hinge out there (we use Salice as a standard), and the 1 1/2" overhang doesn't exist. Back in the days before the CNC cut our cabinet sides, we had a jig that cut out something like a scoop from the cabinet side. We would then edgetape the inside of the scoop by hand. Now with the CNC, we use the same process, but the CNC cuts the scoops in the cabinet sides and the door actually mounts with a full overlay hinge to the end panel itself. The whole thing is a time-consuming business, so when we can we avoid it we do, and when we can just veneer the end of the cabinet, we do that too.

From contributor P:

On my frameless stuff, I build my end panels with a 3/4 x 1 1/8 solid stock edge, so the finished end lips over the face of my frameless case by 3/8, and planes out with the face of the adjoining door. 1/2-crank hinge works perfectly. I use a similar detail on my scribes. Consequently, everything is balanced and in the same plane. Easy and fun!

From contributor D:

We do not overlay every job - if we do, it is around 6-12mm (1/4-1/2"), only to hide the shadow line between door and case. We use full-overlay hinges and the extended applied ends do not interfere at all. We process applied ends exactly as the case parts by simply edgebanding.

From contributor D:

I see what you are saying - apparently you are trying to cover the applied end, which we never do. It is simply a design feature.

We use a/e's mostly, if there is a level change on upper cabs where the next cab is up or down or in or out (microwave cab would be an example). Some frameless guys use a/e's in base cabs between corner lazy susan cab and next cab to avoid interference with knobs.

From contributor S:

If your cabinet box is 24" deep (and back to the wall), then the applied panel should be 24" + door thickness + door outset. Add another 0.25" for an optional scribe fit to wall (high end way).

From contributor T:

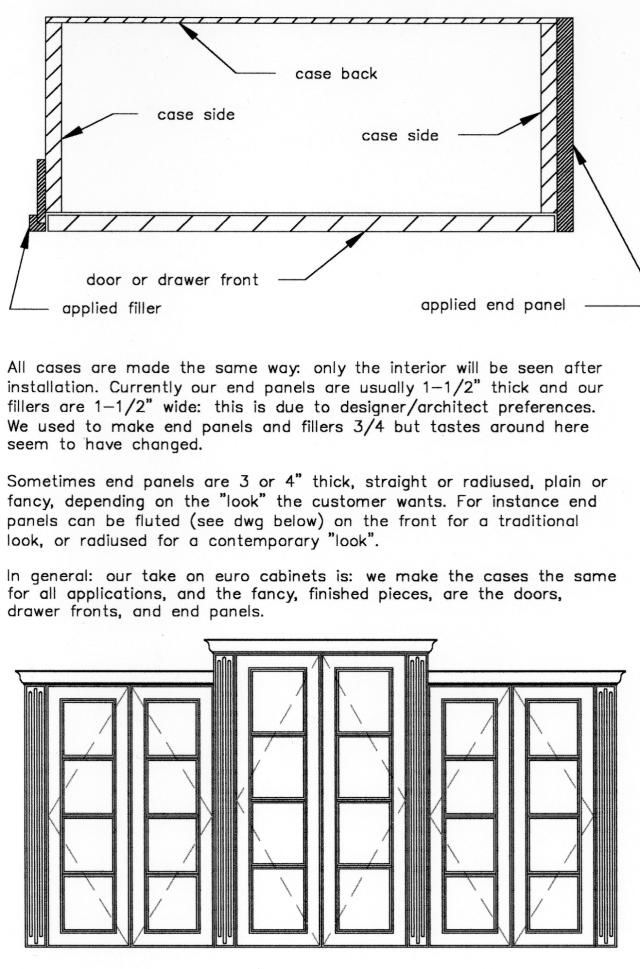

We make the end panel overlap the edge of the door.

Click here for full-size image

Click here for full-size image

From contributor C:

We build frameless all the time and the real question is what the client expects - to see the end panel from the front or the door continuing to the edge of the cabinet. If they're okay with seeing the end panel, then we would use a standard full overlay hinge and hang the door on the cabinet end (allowing the margin for between the door edge and the end panel). Then attach the applied end even with the face of the door. If they prefer the door covers the applied end panel, we sometimes hold the interior end back 3" to allow hinges to be directly mounted to the applied panel using again the full overlay hinge. This works really well, and gives the client just what they want.