Question

After a few years of running windshield washer fluid or water and dish detergent for a blade cleaner, I have finally switched to diesel and bar oil at a very slow drip for this winter. I have been using diesel and bar oil in a spray bottle as needed for a long time, but this is the first time I have used it in the gravity fed tank full time.

I run Timberwolf 13' 9" x .045 x 1-1/4" blades, and have had excellent success with them over any sawmill brand blade. The problem over the past few years has always been when the temperature drops below 32 degrees on the mill's steel, the blades start to break. They generally do not break while in the wood itself, but usually right as the blade is started up, or while in idle as I remove a slab or flitch. This problem never occurs when the temperature is above freezing.

The problem was always much worse with windshield washer fluid, but now not as bad with the diesel/oil mix. It is still occurring, though, and I cannot figure out why. The blades themselves can either be brand new or resharpened once or twice. I would blame this on the blade manufacturer, but it is not occurring on the blade's weld. My band wheels are perfectly aligned, and so are the guides, with only faint pressure on the blade itself. I assume the blade tension is correct, for the hand crank tension goes to its designated line, and the tension spring itself was recently replaced. The blades are also being run slightly tighter than Timberwolf's recommended "flutter test." Any help is greatly appreciated.

Forum Responses

(Sawing and Drying Forum)

From contributor S:

I've been running diesel for a few years now. 1/2 gallon of diesel sure beats 10 gallons of windshield washer that still freezes up in real cold weather. I've never noticed any difference in the cold with blade breakage. I did get a bad box of 10 a while back that all broke before the second sharpening, then bought blades from a different roll and back to normal 5 to 10 sharpenings.

You might want to look at adding a diesel "wick" setup instead of just dripping it on there. One more thing... I've run both .045 and .042 blades, and I couldn't see any real improvement in the .045, but the .042 are slightly thinner, a little more flexible, and seem to last a little longer without breaking.

I send all my blades out for resharp to Timberwolf's division Gooseneck machinery in upstate NY, and I am not resharpening myself. All my blades in cycle are either used once or brand new, and I do not think gullet cracks can be a problem here, for it is happening on both, and probably more often on the new blades.

I feel the whole issue is about blade contact to the wheels, and maybe the faintly rougher texture of a used blade holds better than a slick brand new one. I am going to try the straight diesel and see what happens.

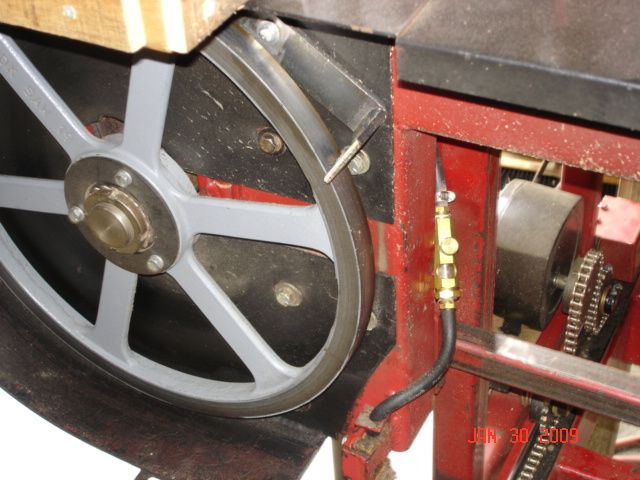

Also, for all of you that run the all-steel wheels, I have made gravity steel scrapers that help to make sure there is as little vibration added to the blade from the steel wheels as possible from sawdust buildup. I got the idea from the Morgan resaw I bought last summer.

Contributor R, keep us posted on those steel wheels. Does it cut straighter with them also? Are they crowned or not? If not, they wouldn't cause the blade to cup like v belts do, and should cut better. Did you get that energy cable set up yet? Nice looking lube system on your mill. I'm still using the drip system. I mounted a 4" linear actuator on the log dog for up and down. That sure saves a lot of steps when sawing by yourself or with someone that doesn't pay attention.

When the blade is not in the wood, do you see any up and down vibration? Ask about trying .042 blades or a different tooth set or hook angle. You might also want to consider trying some Wood-Mizer blades for the winter. I believe they have a frozen wood blade that might work better for you. Good luck... It's 11 degrees out today - no sawing for me.

I have an idea on your scrapers - you could attach a small spring to maintain a little constant pressure between the scraper and wheel. When I saw pine the pressure on my wheel scrapers really helps keep the buildup off the wheels along with the diesel fuel. The less pressure I run, the easier it is for the buildup to occur.

Contributor S, Bill has installed his energy chain and it is working like a charm. It involved a lot of changes, but he did a super looking job. He has his setworks mounted where that cow pile of a reel system the manufacturer refuses to fix was located. It's funny they have an energy chain system on one of their mills, but not on the most popular one. He is going to ship my energy chain to me soon, but in no hurry until spring.

The steel wheels are super and I acquired them used. The drive wheel was damaged during shipping and took a while to repair. TK wheels have no crown and I am in the process of making an arbor to mount them on so I can put them in a lathe and really true them and qualify the sides also. They are running out on the OD about .007" and Mr. Cook said this was within operating range, but they shoot for .003". Bill had steel wheels on his mill when he purchased it and was very helpful in my change over. The learning curve on the tracking was made much easier because of him.

I would love to have some pictures of your new linear actuator. TK wants $2400.00 to upgrade to their new system and I would also like some pictures of it. It could probably be built for a few hundred bucks.

I also can not stand the smell of diesel fuel, and with the felt system that wipes against the blade, I use so little of it.

Contributor R, this might be a little hard to explain. The scraper is only 3/16 wide and the wheel has a surface length of all most 60". That means that there is 320 times the surface area on the band wheel vs. the scraper. The scraper should wear out long before the wheel.

The steel wheels come crowned from Cooks. I only had to buy one set of the wheels, because when I bought the second mill, steel wheels were stock. It is amazing how much smoother the blade runs with steel wheels vs. belted wheels.

Contributor R, my linear actuator works great, but was a tight fit and you would need a couple more wires to run it, which should be no problem if you get that energy chain going. Hard to believe TK won't get a real cord reel. I've had 0 problems with my setworks after I put a good one on. With my linear actuator I had to make the log dog stay upright for about 5 inches closest to the stops due to clearance with the hyd motor. I'm thinking of converting it to an electric window motor which should be a little more compact.

Contributor S, thanks for the information and I understand from TK that the reason they switched to v-belt wheels was most people could not maintain proper tracking and the belted wheels were more forgiving. I am getting more board feet per blade, cuts are much smoother, and reduced the vibration caused by the v-belts on the drive wheels. The first blade I ran with the new steel wheels and diesel ran perfect and when I pulled it off after about 400 BF, it still had most of the writing on the outside of the blade. This showed it was tracking perfectly. Knock on wood I have not had a blade break with the steel wheels so far.

As to what I think about crowned versus flat wheels, they both should perform great and the crown is not enough to cause a real problem. I have worked on metal cutting band saws in manufacturing and without a crown, they will not track at all. That is why I was a little surprised to see that TK used flat wheels in the past. The crowned wheels may be a little easier to set the tracking. I will be happy with or without a crown because of all the advantages. As I stated above, I will never go back.

What are the differences between flat and crowned steel wheels? Contributor A, your scrapers must eventually wear to match the crown of your wheels, but as they wear further from that, the scraper must start to ride the sides of the wheel, no? I see advantages of your scrapers for sure, and that maintaining them would just become routine maintenance. Due to the fact that this will induce wear on the steel wheels, would it be better to make the scrapers out of aluminum or some softer metal? I don't know if this extreme is possible, but could your wheels be balanced enough to have the scrapers fixed several thousandths away from the wheel?

Contributor A, I think that if anything lasts for years, that's great, but wouldn't it be better for the scrapers to be aluminum? Maybe aluminum would be too soft and wear to quick, but there must be some kind of material of the right hardness. Maybe that low friction plastic stuff some companies sell for machine fences and setups?

Maybe literally trying to reinvent the wheels becomes more time consuming than dealing with what you know works.

I am still using up my 5 gallon 50/50 mix of bar oil and diesel, am about halfway through it. I am anxious to try straight diesel, but want to fully experience what I have right now because it is working very well.

The only issue I am having now is sawdust sticking to both the top and bottom pieces in each cut I make while running the diesel oil mix in freezing conditions. It freezes up pretty badly, and I have to wire brush the sawdust off by hand and blow it off with my compressor at 150 psi. Maybe this is moisture freezing up from the log itself?

I do not see this as a set issue because I can run the very same blade in warmer weather with water or windshield washer fluid and blow off any excess sawdust with my compressor no problem.

Maybe the set would make a difference, but I am trying to find an alternative, for the set I have is perfect for black locust, and this wood is very finicky as to how low or high the set is.

I wonder how hard it would be to rig my 5 gallon tank with a safe heat source around all the sawdust. I think this might make sense and work best with my small wheels with v belts.

When I first started buying Timberwolf blades a few years ago, Tom there told me about the diesel/oil mix and I believe he said the diesel keeps the blade clean, and the oil keeps the v belt from rapidly deteriorating. If I run straight diesel will my v-belts deteriorate faster? It's weird how easily some things melt in contact with other things. I remember as a kid I had different plastic lures in my tackle box and when some of them contacted each other, the plastics melted themselves.

I tried the mix and the diesel seemed to dissolve a lot of the tackiness from the bar oil and the straight worked better, and metered through my system better. However you may watch for black residue on your cuts because when using v-belt wheels, the drive wheel will slip inside your blade and leave the residue from the belt on your lumber. As to the life of your v-belts, they should be fine and I used to change mine quite often even when using pin-sol and water.