Working with Zebrawood

Tips on working with this interesting (but stinky) wood species. October 25, 2006

Question

I have a request from a client to create a zebrawood desk. I told him I have never worked with it before, but he likes our work and says go ahead. Any thoughts would help. The desk will be 60 by 80 with a veneer top with a flush 1" by 2.5" solid edging. I will be using a phenolic back, but have concerns about the stability of the veneer. Is it feasible to round the solid on a 12" radius? How does it take to steam? What is the best glue to use? Does it eat sandpaper like teak? What is the best way to finish it? Has anyone used Good Stuff? It is a gel urethane for butcher blocks. Did you like the product? Can it be tinted?

Forum Responses

(Cabinetmaking Forum)

From contributor M:

I've used a little zebra wood. The veneer splinters like crazy and is very brittle. Solid isn't too bad, but I've never bent it with steam.

From contributor T:

We've cut some zebra wood, using CNC with .250 e.m. the feedrate 225 ipm at 13000 rpm with .500 step down. The finishing was done elsewhere. I would say zebra wood has a strange smell. I assume when sealed, this will go away. But that is what stands out most. Time to experiment.

From contributor B:

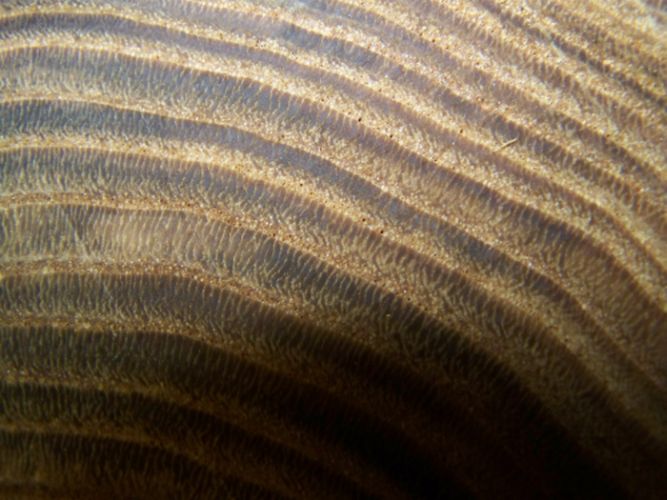

Zebrawood looks amazing if you do a good prep job before finishing, but as a warning, the smell of it when you are cutting/sawing/sanding isn't pleasant by any means. It cuts well, but it is on the harder side. I've never worked with zebrawood veneer, only solids.

From contributor G:

I did a library a while back using zebrawood veneer over particleboard. I had the panels laid up by another shop and applied 1/4" solid zebrawood to the edges. I believe they used plastic resin glue. I also edged the boxes with zebrawood. The job was finished with oil. I have also built guitars using solid zebrawood - and yes, it does stink! One of my suppliers just got in some curly zebrawood - really cool stuff - $25 per B.F.

From contributor A:

I've used zebra wood in many projects.

- saws very well

- stinks

- planes very poorly due to interlocking grain. I joint one face and accept some tear out. Then go immediately to the widebelt for the rest of the thicknessing.

- sands fine without much clogging

- finishes nicely. I've used both Waterlox and Fuhr waterbased over a shellac sealer.

- definitely not a candidate for steam bending