Message Thread:

Problem wiping glaze

6/11/15

I've have had this issue for a while and posted it here but still can't seem to achieve what I'm looking for. This is my process.

Chemcraft Aqua prime, then scuff

Chemcraft Varsisett precat paint

Mohawk finishers glaze (oil based)

Conversion varnish

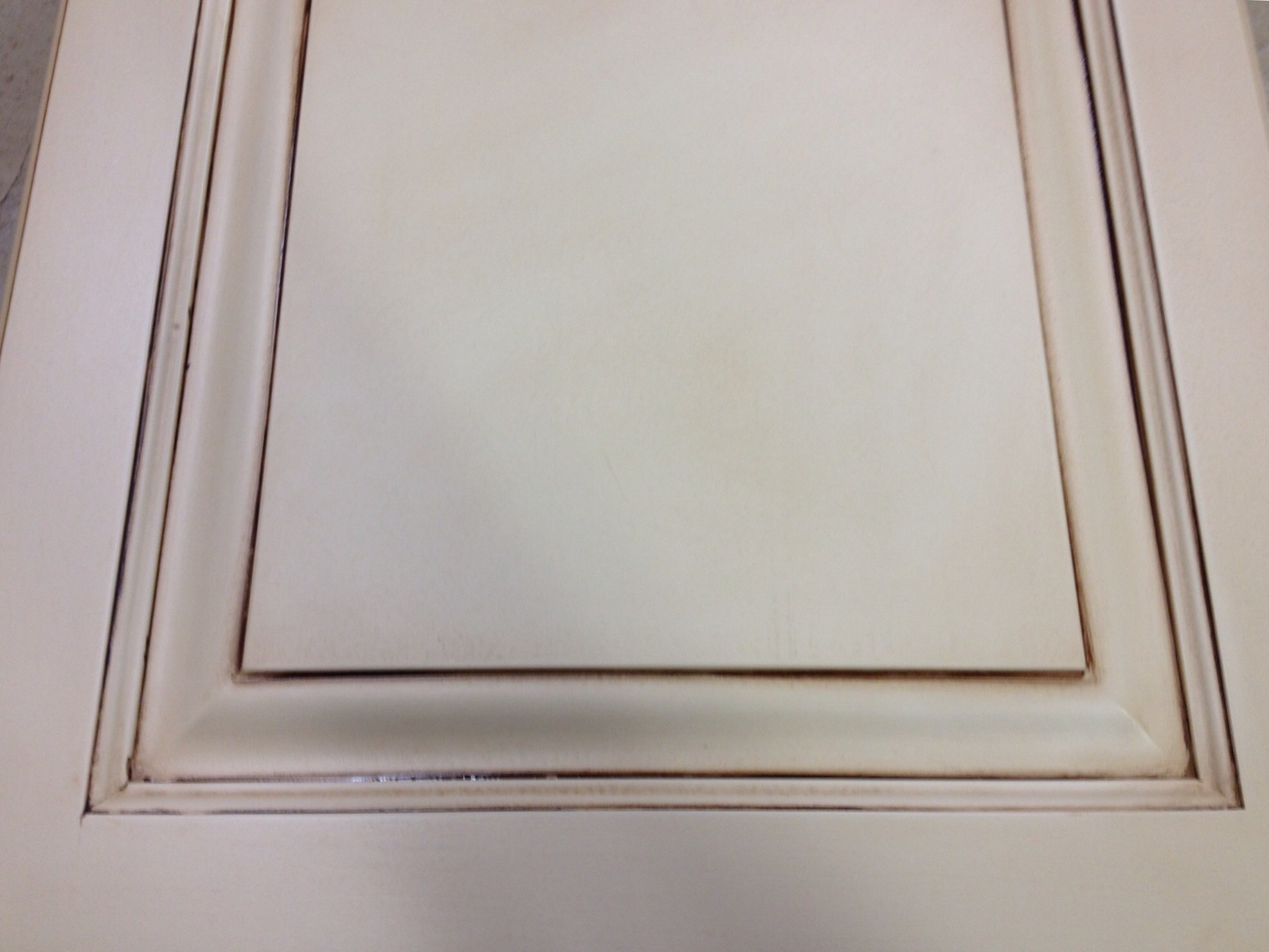

My problem has always been that I just can't seem to get a clean look on the flat surfaces. It always looks grungy, even after vigorously wiping it. On the last set I would glaze a door and then go back over it with paint thinner and clean it and it worked pretty good. Yesterday I did the same thing and the thinner worked but this morning I couldn't even get the thinner to bring the glaze off. It's kinda like the glaze is biting down into the paint somewhat. My teck guy from my distributer told me to glaze the door and let it dry and then go back over it with a scotchbrite pad and remove the grunge which I tried and it made it a little better. I need to figure out a full proof plan to always get this right, I kinda feel like I'm in trial and error mode every time. I do know that humidity is playing a role in this problem because glazing is harder in the morning than it is in the evening. I'm also thinking that the glaze is biting down into the paint. That's my two thoughts on the problem. I'm also trying a different method on a couple other doors, I sprayed a coat of glaze on them and decided to just let them dry and then scuff the glaze off tomorrow, have no clue how it will look. I've attached two photos, notice the grungy look on the one and the other is one that I cleaned with the paint thinner. Any thoughts on what I'm doing wrong?

View higher quality, full size image (1974 X 1481)

View higher quality, full size image (2048 X 1536)

6/11/15 #2: Problem wiping glaze ...

The first pic is the grungy one, notice the center of the panel, the second is the one that is cleaner, the lighting made it look more yellow but it's actually cleaner.

6/11/15 #3: Problem wiping glaze ...

You might try spraying a coat of vinyl sealer after the paint and before the glaze. It's easier to apply & wipe off the glaze (or do dry brushing) when it's going on top of sealer. That's the way my shop's been doing it for years with good results.

6/11/15 #4: Problem wiping glaze ...

I actually thought about spraying a coat of cv before the glaze to seal it better and see what happened. I've never used any vinyl sealer. Do you think the cv would serve the same purpose? Thanks for the response Duster.

6/11/15 #5: Problem wiping glaze ...

There might be some other solvents in the Mohawk Glaze that's biting into the Paint. Have you tried mixing your own glaze ??

Ive always made my own concoction with Paint Thinner or Naptha and an Oil based colorant like UTC. A teensy weensy bit of Linseed Oil will slow down the dry time so you have time to work it. Once in awhile someone would provide me with a sample and if I didn't have a particular color on hand, or didn't want an entire Quart, I would hit a good art store and pick up a tube of artist oil colors.

If you apply a barrier coat of Vinyl Sealer over your Paint color...its less likely to look muddy and will be a lot easier to remove the excess.The Glaze will look cleaner over a clear coat than a colored one. ( especially a White color )

If all your doing is applying the Glaze to the nooks and crannies, just put your Glaze in a plastic squirt bottle, cut a small piece off the tip of the cap and squeeze it where you want it. No need to do the entire door if your ending up wiping 99% of it off.

If you do decide on trying your own glaze with the ingredients I mentioned, you can let it dry until the cows come home and when you attempt to remove any excess, you wont need a Scotch Brite or Steel Wool. Just dip a rag ( not real wet...but damp ) in some Paint Thinner and swipe it over the area you don't want glazed.

Presto...Glaze-B-Gone.

6/11/15 #6: Problem wiping glaze ...

To add to what has already been said, I like to use a thin wash coat of vinyl sealer over my color coat , than glaze than another wash coat of vinyl. I use a thinned down wash coat so as to not get the vinyl too thick but still allow for easy wiping of the glaze and isolating the glaze from the CV top coat. I don't feel comfortable spraying CV directly over any glaze.

6/11/15 #8: Problem wiping glaze ...

I have been applying oil glaze with hair color bottles with fine-medium tips from Sally Beauty Supply. Gets the exact amount you want right in the recesses and details, quickly and cleanly.

You can put the glaze exactly where you want it and unless the tip is worn, you seldom have to even wipe it. Adjust flow with squeeze pressure.

Keeps base coat clean as well.

Give it a try.

6/12/15 #9: Problem wiping glaze ...

Vinyl sealer as has been stated above is the answer. It stops the glaze from biting into the paint. Also makes wiping off more cleanly much easier and paint thinner will take off the rest. Vinyl sealer before glaze and vinyl sealer after glaze and before final topcoat.

6/12/15 #10: Problem wiping glaze ...

You might consider this:

A coat of clear gloss finish before glazing will help control how the glaze sticks. I believe this is because the gloss finish has no talc or roughness for the glaze to hang up in. This, with a little scotch brite works for us.

6/12/15 #11: Problem wiping glaze ...

Do you guys that apply the vinyl sealer sand it before or after the glazing?

6/12/15 #12: Problem wiping glaze ...

On a glaze over a pigmented coating I like to have the pigment coating as smooth as possible prior to applying the barrier coat.

Generally I don't sand or scuff the barrier coat as the glaze will end up in the scratch pattern. This is especially true when applying the glaze over a light colored pigment coat.

A brushed on glaze over a stained finish is handled differently.

6/12/15 #14: Problem wiping glaze ...

Mike - we do sand the vinyl sealer with 320 grit paper before applying the glaze. We haven't found it necessary to spray another coat of vinyl sealer after the glaze, so we finish with precat lacquer, usually 2 coats. We don't use CV, so I'm not sure how that would work. I think doing some tests would be in order, but I do think vinyl sealer would help your process.

6/12/15 #15: Problem wiping glaze ...

My process on pigmented finishes with glaze.

1. Spray one light coat of sealer, sand, spray second coat of sealer.

2. Spray 2 coats of colored finish. Sand between coats but not after second coat.

3.Apply glaze with rag and wipe off as much as possible with clean rags.

4. After glaze has thoroughly dried, usually overnight, I take a used sanding sponge and clean up flat areas and places where I do not want the glaze.

5. Blow and wipe off and apply clear topcoat. Finished!

I use all pre cat finishes.

6/12/15 #16: Problem wiping glaze ...

I use a pin striping brush and tape. May sound weird but I get really clean results.

6/12/15 #17: Problem wiping glaze ...

I really appreciate all the good responses. My rep stopped in today to try to help me figure out my issue, which he didn't do, but at least he came. He is sending me some break away glaze to try? I've never used it but he said that you spray it on and let it dry and then wipe it off? He also is sending me some water based glaze to try with the 2k poly that chemcraft has. I would have switched to the poly two years ago but they didn't have the glaze then. So we shall see I guess. Oh yea, he is also sending me some vinyl sealer but he didn't like the idea of doing the vinyl over the paint, he said it was to soft... Have any of you guys tried the break away glaze or the waterborne?

6/12/15 #18: Problem wiping glaze ...

Not really an answer for you, but you are putting a CV over a pre-cat? Harder over softer is usually a recipe for disaster.

I'd use a CV for the paint coat and then a CV for the clear coat. Usually an oil base glaze should be sandwiched in between two vinyl sealer coats unless is is specified to be used without.

6/12/15 #19: Problem wiping glaze ...

you should either use the gloss version of the pigmented finish, or use a clear gloss sealer. also you should use chemcraft glaze. the chemical makeup will likely be more friendly with your chemcraft coatings

6/12/15 #20: Problem wiping glaze ...

For a breakaway glaze we always use a dealer coat between glaze and base color coat and initially wipe the glaze and the scotch brite after to add depth and even out anything. For pinstripe glazing invest in the CA technologies glazing gun. Money well spent and little to no elbow grease required. If CA technologies raised the price on the gun to $1000 I would still consider it a good deal.

6/12/15 #21: Problem wiping glaze ...

I agree with Leo G. CV over pre-cat is not good.

I do Mohawk glaze over pigmented CV (no scuff) and topcoat with CV. If you leave too much glaze on , you can have problems, but glaze between CV has worked for me for 10 years.

One tip is to wipe glaze with a glazed soaked cloth vs. a dry clean cloth. The wet cloth releases some of the drying glaze. Think of glazing as tone and age and not Pinstriping like the factory cabinets.

dub

6/15/15 #22: Problem wiping glaze ...

heres a very inexpensive, very helpful tool for what your trying to accomplish : http://www.amazon.com/Paasche-FP-1-32-Flow-Pencil/dp/B000FMFMVA

Flow Pencil

6/15/15 #23: Problem wiping glaze ...

I appreciate all the good responses, they've been a lot of help. After doing some research I've ordered some breakaway glaze. I have high hopes for this method. Do any of you guys use breakaway glaze?

6/15/15 #24: Problem wiping glaze ...

I sometimes use the breakaway glaze.

Works well, applied at low pressure and scuffs off easy with a scotchbrite.

It can leave an overall dirtier appearance than a cleanly wiped oil glaze.

It can also bite hard into a undercured precat so let it cure overnight before glazing.

6/16/15 #25: Problem wiping glaze ...

Thanks for the info Jim. What color scotchbrite pad do you recommend for the scuffing?

6/16/15 #26: Problem wiping glaze ...

Simple: you cannot sand before you glaze. Most responses said the same thing only in more detail.

Do NOT sand before applying glaze

6/22/15 #27: Problem wiping glaze ...

This is not the exact look you are going for, but I thought it may help in your process. I took this video last night while doing pinstripe glazing on a mitered maple door. More of a color fill look rather then glaze but it is a very popular style for us. Maybe a little too "factory" for some but we get customers that want the glazed but not "dirty" look.

I have used the glazing pen mentioned above and had little to no luck with it. The CA technologies gun on the other hand has paid for itself 100 times over.

Hope this helps.

Link

6/22/15 #28: Problem wiping glaze ...

Man Dave, that looks good. I appreciate you taking the time to show your method. I too bought the flow pencil and didn't have much luck with it. Is that just a regular oil based glaze that you are using? The reason I ask is, my distributer had me trying some glaze that was pin striped in but it supposedly melted into the finish and you didn't have to top coat it. It evidently didn't go over well and they have discontinued the product. They have sent me a sample of breakaway glaze that I'm going to try on a sample door and see what it looks like. I'm also doing one one and trying the vinyl sealer over the paint an see what that looks like. One thing for sure, I never want to do another one the way I have been. Thanks again for filming the video!

6/22/15 #29: Problem wiping glaze ...

I have the paint store pigment clear laquer for my glaze (they do a lot of toning and pigmenting for us). We don't have any solvent compatibility issues then and we can coat over within an hour or two if we need.

It is very viscous but I like it that way for flow out. Vertical surfaces you have to keep a "controlled drip" as you work down but works well for me.

Anyone that wants to try the "flow pencil" I will send you mine...and then you can continue to pass it on!

7/7/15 #30: Problem wiping glaze ...

We changed to breakaway glaze, works great. On sanding we have found that the fine sanding pads are alright before glazing but not scotchbrite pads.

My clients seem to like the glaze on flat areas also, if your market is different the flow pencils or glazing guns may be what you should look into.

Personally, I think glazing and striping the profiles are two different animals.

|