The purpose of a guide is to assure that the blade does not deviate significantly from its desired path. This is done in two ways.

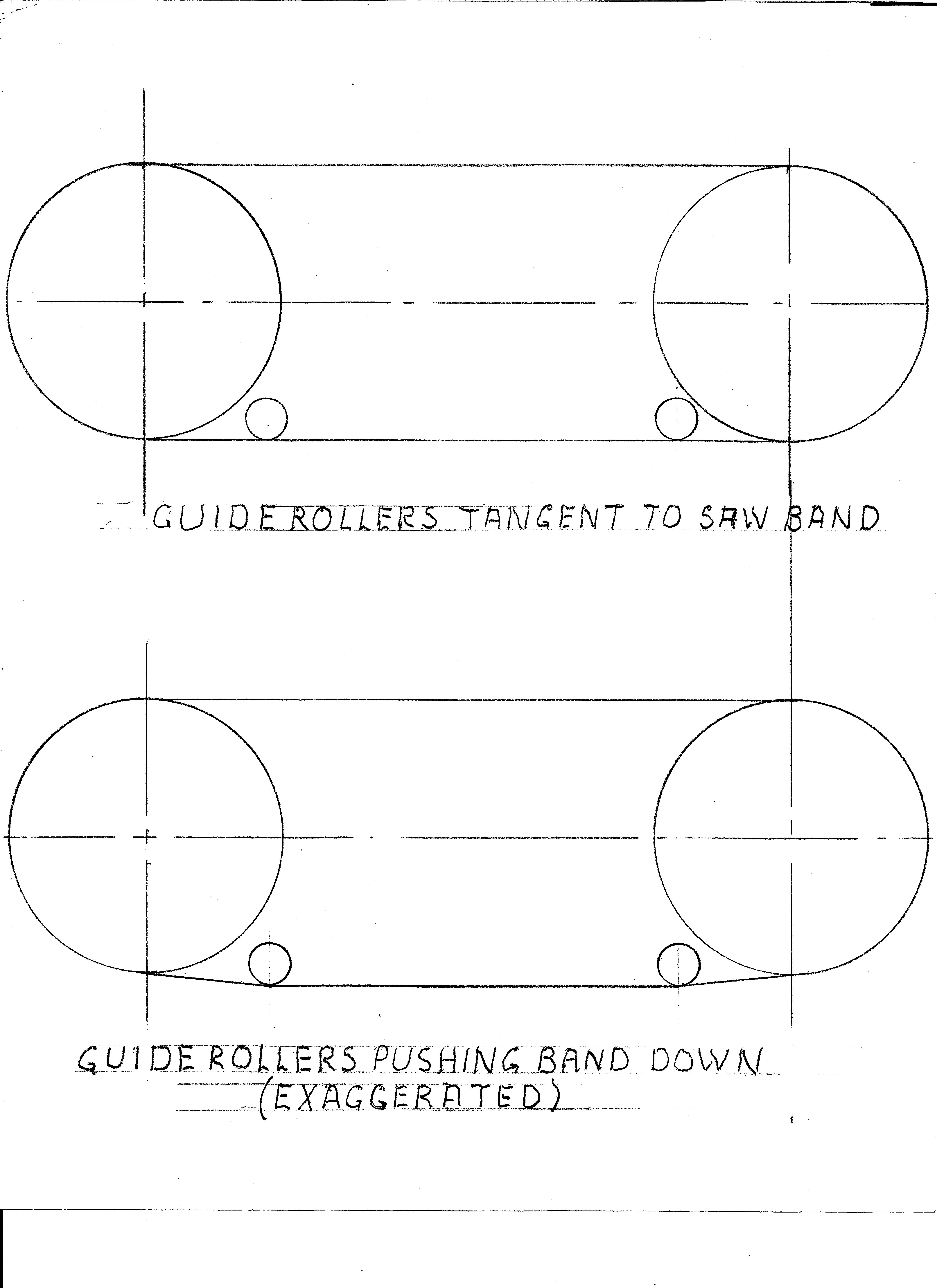

First, if the blade has excess energy (shows up as movement) that develops while cutting, the guide will absorb some of this energy. Overall, this means that the blade will take the shortest path between the two guides, as it would take energy to do otherwise. Sometimes, especially when the guides are in perfect alignment with the natural path of the saw blade (your first figure), there will be a guide on each side of the blade, rather than having offset and then using only a guide on one side.

The second is that the guides shorten the distance between the two main wheels and this results in the blade, where the cutting occurs, having a higher resonance frequency, which means the blade is much less likely to vibrate, as the resonant frequency from the spinning of the blade around the wheels and the frequency between the guides are far apart. If they were close, you can get a standing wave, which means the blade "vibrates" and does not cut straight. Incidentally, this is also why the guides are moved, during sawing, so that they are close to the log surface, again shortening the span and raising the frequency.

Because the guides oftentimes are touching the blade, they are designed to be frictionless to avoid heating. Heating would cause unwanted blade movement and potential failure. So, spinning, roller guides do not frequent inspection to assure they are spinning without restriction.

These concepts apply to band and circular of all sizes.

Hope this helps.