Hi Stephan,

Please allow me give you some serious advice on checking out ANY software program.

There are two main problems when shopping for software:

1. Software salesmen are trained to stay in control of the demo they give you. Generally you will receive a canned demo that has been practiced to perfection, giving the impression that the software program can do just about anything.

2. A trial version given at a nominal fee or even free is generally a waste of valuable time because you have to go thru days, weeks, or even months to learn a program just to see if it fulfills your needs. Then, if it does not, you have to start all over again with yet ANOTHER program.

To avoid both these pitfalls, may I suggest the following:

1. Call the software company for an online demo, making sure they understand you want to see how their program fits your needs.

2. Ask questions that are important to YOU, not the salesperson.

3. Take the salesperson out of his comfort zone and ask SPECIFIC questions on YOUR methods of pricing, construction, or CNC operations. It cannot be over-emphasized for you to be prepared to ask in-depth questions and ask the Software Representative to demonstrate the making of cabinets YOU make.

4. Do not put too much importance on references....generally they are handpicked and will always give a good review.

5. How easy is it to edit cabinets and change various aspects of those cabinets?

6. Make sure your questions are answered by SHOWING you how your issue is resolved. DO NOT be satisfied with a verbal response. Verbal responses do not show how the software operates.

7. You are guaranteed to require technical support. What is the charge for technical support? How does the company provide technical support? Is there a charge per incident? Are there yearly fees?

8. How does the company handle computer crashes? Are there fees involved if your computer crashes, if you lose a key, etc?

9. How are you expected to learn the software? Written documentation? Video tutorials? Classes to attend? Onsite instruction? What costs are involved?

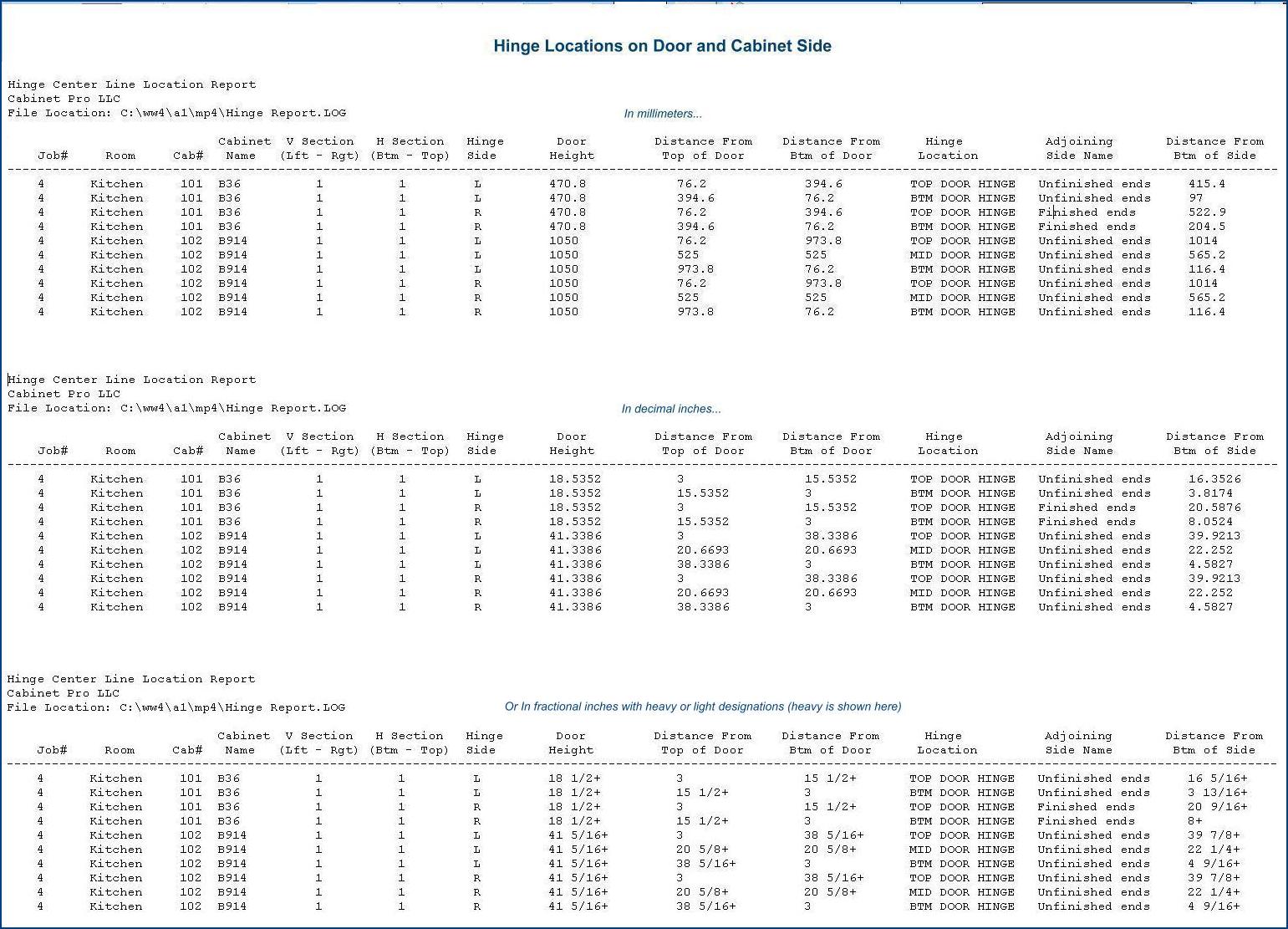

10. Know what your needs are before talking to a salesperson. Do you need design capabilities? Shop Drawings? Bidding? Cutlists? Door Reports? Face frame or Frameless? CNC support?

11. How is the software protected? If keys or dongles are used, how much will it cost if they are broken or lost? (You are virtually guaranteed to lose or break keys!)

12 How are reports customized? Ask to see a report according to YOUR expectations.

13. Have a pretty one-of-a-kind custom cabinet in mind, and ask the sales person to show how it would be built according to your specifications.

14. If you are inquiring about a CNC version, ask TO SEE how the software handles the generation of CNC code when changes occur, such as when a new batch of material with a slightly different thickness is applied to the job, or when edgebanding changes, It's pretty common to receive a new batch of say, prefinished maple with a thickness different from the last batch you received. How are insets, dados, and depths of cut handled in this situation? If you change edgebanding, does the location of machining change as well? These are just a couple of examples of the kind of questions to ask.

15. If you are inquiring about a CNC version, how are drawer guide holes, hinge plate holes, and other hardware machining handled? BE SPECIFIC.

16. Ask to have the program machine at least one part according to how you would machine that part.

17. Although graphics are nice, DO NOT be dazzled by great graphics thinking that the manufacturing end is just as nice! The manufacturing end will be your bread and butter. Make sure it is quick, efficient, accurate, and relatively straightforward.

18. How is hardware, accessories, and pricing handled? How do YOU price out your jobs? Ask the salesman to demonstrate pricing according to your method of pricing.

19. Do not be overly concerned if the software is not particularly easy. As long as the sales person can demonstrate to you the quickness and efficiency of the software, you will be fine. You will have reason to learn the software if you know it will function according to YOUR NEEDS. Ease of use of a software program like this is usually inversely proportional to its capabilities. As long as you have good technical support and a good training program (see #7 and #9 above), you will do well with learning the software.

If these things cannot be shown to you quickly by someone who is WELL-VERSED in the software you are contemplating, then you can rest assured that it will take you much longer to accomplish the task when you have the software on your computer.

On the other hand, if these things CAN be SHOWN to you quickly by the saleperson, then you will probably be happy with the software. Know that there is no software that will do ALL that you want.....but the software you finally decide upon should do ALL that you NEED, and the MAJORITY of what you WANT.