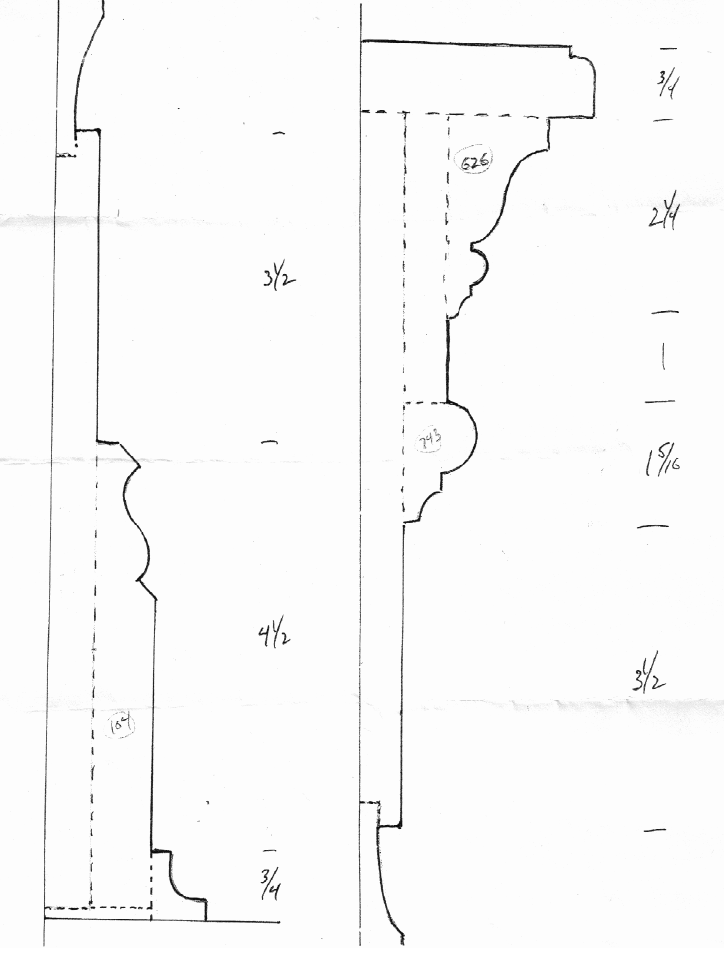

Profile Sample

We had three radiator covers to make. Each had to ‘fit’ within the wainscot very well…(both in terms of size and style). We first created the covers faces in the shop and sealed them well, backside and front.

Radiator Covers

Radiator Covers

I usually do a drawing of the frame and panel placement right on the walls. This verifies the sizes of the panels to be made back in the shop…but it also helps the client to envision what this ‘wall covering’ will look like. This becomes even more critical for those diamond-shaped panels climbing the staircase. Here are two shots of the staircase being installed.

Staircase

Our installation time was somewhat limited so we began installing panels while our painter began placing a final coat on those sections already completed. Here are two walls in the dining room freshly done.

Completed Wall

The only way to see the whole job is to show this short video I managed to grab when I returned two weeks later to do another project for them. The good work paid off, it seems.

VIDEO HERE

Final Project

If you like our work, you might wish to check out our gallery at:

Hudson Cabinetmaking, Inc.