Best Method for Leveling Base Cabinets

Cabinetmakers compare installation methods for base cabs, including ledgers, ladders, and adjustable levelers. November 29, 2014

Question

I posted this question a couple of years ago and received some good answers but Iím hoping to get maybe a little more in-depth info. For years to level base cabinets I used shims back and front, then someone posted a response about using a ledger strip screwed to the wall, so I started cutting a notch in the back side of my cabinet sides and letting the 1/2'' cabinet back come down to that notch. Once the ledger board was leveled and screwed then the back of the cabinet sat on it and we use a leveler on the front which is basically a bolt with a plastic foot that screws up in a T-nut and we adjust it from the front underneath the toe kick that is cut 1/2'' shy of the floor. We then cap that hiding the leveler and the crack.

I'm satisfied with the leveler in the front, but the ledger board actually took longer than using shims. I don't like the plastic levelers and I don't want holes in my deck with plastic caps. I've heard of something called a ''ladder system'' but I don't know how it is done or how efficient it is. Then there's the French cleat. The EZ-level system looks brilliant but over-priced, it would be hard to justify the cost especially on a lower priced job. Just wondering if you guys would elaborate on how you do it, as far as method and the steps you take to get the job done. I'd like to find a way of doing it that is strong and doesn't take half the day just to level.

Forum Responses

(Cabinetmaking Forum)

From contributor E:

Go with the Ladder. Build what looks like a small wall out of plywood, I use 4" rips. Place on the floor, shim and then screw to the back wall and/or floor. Youíll be ready to slide cabinets from furniture dollies on to kicks. It gives you better yield on panels by getting six cabinet sides instead of four per panel.

From contributor V:

"I don't like the plastic levelers..." Please elaborate on this and maybe we will be able to help you change your opinion on them.

"....and I don't want holes in my deck with plastic caps." Except for the first job that I did years ago, before I understood the system, I have never bored holes through the decks of cabinets, as it is not necessary. On some cabinets it will make your life easier, but it is not required. Leg levelers and the hanging rail system make installs somewhat enjoyable for me and I would hate to work without them.

From contributor M:

We just build ladder frames, like Contributor E says. Keep your middle ladder pieces narrower so you can scribe to the floor easier. My hardware salesman talked me into a whole case of plastic folding levelers. Biggest pain you could imagine.

From Contributor W:

Ladder kicks for sure!

From contributor C:

I use levelers, screwed on from the bottom, no holes thru the deck. I've used ladder bases too and really liked installing that way but the sockets for the levelers let me slide my boxes around in the shop, trailer or jobsite without worrying about damaging them.

When I use ladder bases I make the front and any finished end the full width of my toe space and the back and the "rungs" are 1/4" or so narrower. I can set up my laser level to the height of the top of my box and use a 1"x2" with a mark on it the height of my box to set the back part of the kick starting from the high point in the floor. Just slap the 1x2 against the wall aligning the mark with my laser line, pull the kick up snug against the 1x2 and screw the kick to the wall. Then shim the front as needed.

It sure is nice when you can just slide the boxes onto the kick box, screw them together, drop some shims into any gaps between the box and the wall and screw them to the wall. I think I may have just talked myself into going back to ladder bases when my adjustable leg supply runs out.

From contributor N:

I had to Google the EZ-Level that you mentioned and it looks nice. I agree the only real drawback is the price. I could go through quite a few shims and hours for $15 bucks a set, even at a quarter the price if save them for that one in a million scenario. I too use ladder bases, I also glue and pin plywood blocks wherever the gables are so there's something continuous to the floor. I've used the plastic leg levelers in the past and really did not like them. With a levelled base you can gang a run of cabinets together and see what the walls are doing. And the leg levelers carry the weight on the bottom of the cabinet causing it to bow underweight. I always found myself adding shims above the finished toe-kick to help carry the weight in the right spot.

From the original questioner:

I'm trying to picture this ladder system. It sounds a lot like what I'm calling a ledger board, unless what you are talking about is like a 2x4 base that is about 22 deep and then you build your base without a toe kick and then the 2x4 base becomes the toe kick? It would be nice to be able to see some pics of how this is done.

From contributor C:

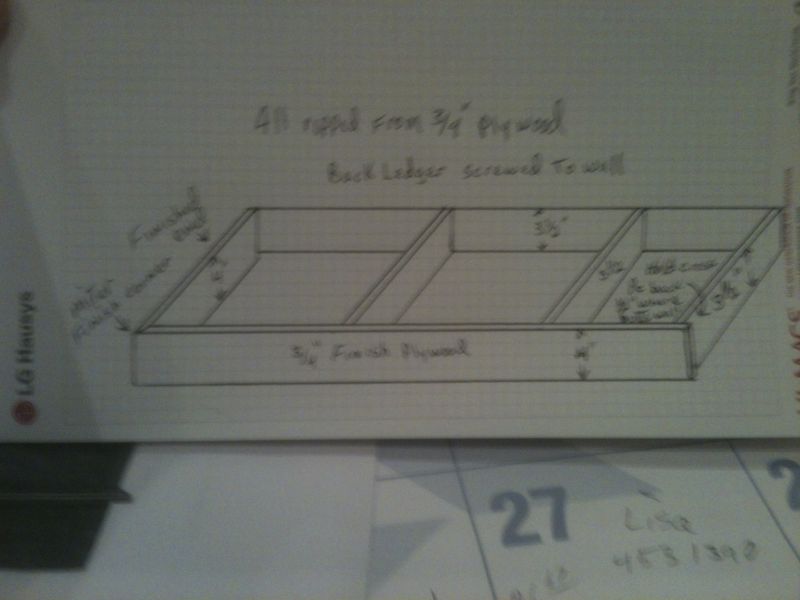

I donít know if you can make heads or tails of this but this is how I do it when I use a ladder base. I donít use 2x4, just 3/4" plywood. I use the finish species where it will show and whatever for the interior. Or you can use scrap everywhere and skin the finished sides with 1/4" plywood. The second method actually works pretty well if the floors are off very bad. You can just make the whole base about 1/2" short and shim it level and then scribe your 1/4" skin to the floor.

Click here for higher quality, full size image

From Contributor W:

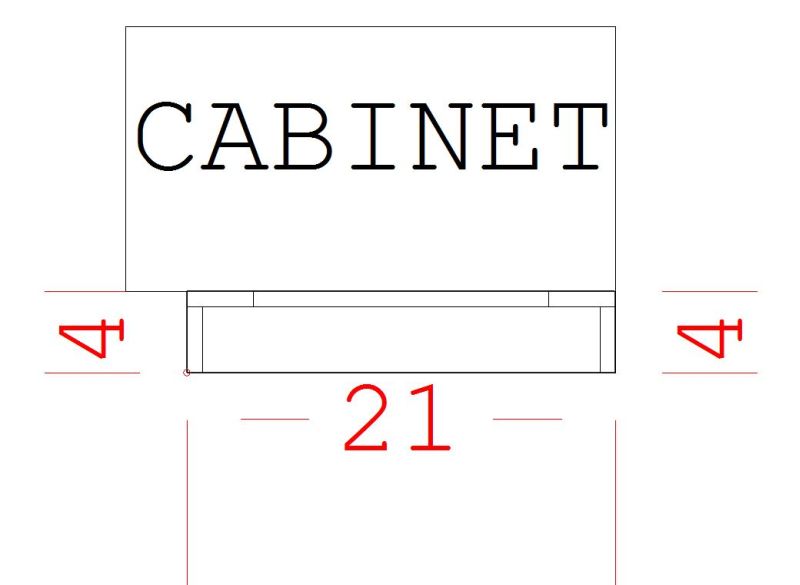

We cut up into 19.5"x3.25" length and store for use. We cut 3.25" rips to length needed and mark an "L" out of it and then use the 19.5" for cross-members. It makes for a sturdy kick and has a plate for attachment.

Click here for higher quality, full size image

From the original questioner:

Ah - now we're talking! Thanks for the sketches, that makes it much more clear. Contributor C, when you say "when I use the ladder base" are there times that you don't? Just wondering how you decide to use the ladder base and reasons? Also, I'm assuming that you guys are building frameless cabinets by the way you are describing your method? I only build face frame cabinets and my bottom rail is two inches and my floor comes to the top of that rail. With the deck being 1/2" thick and my cabinet sides coming down to the bottom of the rail then that leaves 1 1/2" gap from the top of the ladder base to the underneath of the deck?

From contributor D:

The only way I will do it is with a full height gable with a notched toe kick. I would never, no matter what the specs on plastic legs are, ever use them. Just sounds too flimsy. Itís a good selling feature when you can tell your customer that the weight of granite is transferred to the floor on the gable and not resting on plastic legs. And yes only four gables per sheet, but there is a 12" rip left over for uppers. So there is no wasted material. Another added plus is after assemble the cabinets are not sitting on the floor with edging getting damaged.

From contributor C:

No I build almost exclusively face frame cabinets. I use a 1 1/4" bottom rail with a 3/4" deck offset 1/8" from the top of the bottom rail which leaves me a 3/8" recessed area behind the bottom rail. The dimensions in my sketch, if you could even make them out assumed a flush bottom just to avoid confusion. If I use ladder bases and want a 4" high finished toe space my exposed finished toe boards would actually be 4 3/8". Of course my finished end panels which have the deck dadoed into them extend down flush with the bottom of the frame, but my unfinished ends just get rabbeted and stop flush with the bottom of the deck. I hold the ladder base back from any finished end an inch or so it doesn't interfere with the finished panel.

The last time I used that type of base was because I forgot to order adjustable legs. The main reason I use the legs is because once the sockets are screwed on at assembly the boxes can be slid around on the floor without risking damage. Same thing could be done with some scrap blocks tacked to the bottom of the deck, put them where they wonít interfere with ladder bases and you could just leave them on when you install.

From Contributor R:

To contributor W: How do you attach your frame/toe kick to the floor?

From contributor G:

We have been using ladder frames for years. To make them as user friendly as possible the lower rail on our base cabinets is only 7/8" tall with a 3/4" plywood bottom on the cabinet. This way the cabinet sets right on the ladder base. As a bonus there is a little more usable height in the cabinet.

From contributor B:

I have always used leg levelers as they make my life easier when it comes to installation. I get the install completed fast and decrease my time being out of the shop. Bottom line is that they save me time and time is money. I am considering going with the EZ-Level system and will try it out soon. The reason I would consider changing is that it again will make the install even quicker and will save me time in the shop when I attach them to the cabinets. I understand that they can be used on multiple cabinets together. I have been following some of the threads and videos on Lean and I think itís the way to go. Spending the extra time to build a ladder kick and install it seems like a lot of extra work. After all, that is probably why these new systems have been brought into the market.

From Contributor W:

"How do you attach your frame/toe kick to the floor?" After the ladders are shimmed or scribed (which ever) then a corner block of 2x material is placed in a corner of the kick and a tapcon or screwed to the deck then the toe kick to it.

From the original questioner:

I can see all the pros and cons that have been posted. Ladder bases make leveling easier but then you have build the ladder base. Contributor B I think a lot like you also. The EZ-Level system seems to be the fastest and easiest. If it costs $200 for the levelers does it save $200 worth of time and material it takes to do the other methods? If you try them I think we all would be interested in your verdict since no one on here seems to be using them. If I were to use a ladder base I would definitely use leg levelers on it, scribing them to the floor just seems like a lot of effort when you could just screw a leveler stem and be done?

From Contributor W:

I guess I should also point out that 99% of the time there is no fastening to the deck same for the leveler, we have used the leveler (when spec'ed) I have no issue with better or worse, the ladder works and again 99% of the time no scribe is needed yet we had one high rise deck that was out 2" over 13 ' and scribe was needed as one end would have been 6" off the deck.

My golden rule is to test them. We are installing on concrete decks in commercial buildings. It works well for us and the other side of that is here in the south the legs just are not used as much as they might be in other parts of the country. We do fasten the ladder back to the wall and will use construction adhesive and corner blocks if needed, we have units in 15 plus years and with us working in the same buildings most all these years see them all the time and have never had a call back as a result.