Buffing to a High Shine

Other Versions

Spanish

French

Progressively finer sandpaper, then buffing compound, will raise a liquid gleam on a gloss conversion varnish. October 9, 2006

Question

We have a small countertop (walnut) that the customer insists on having the highest possible shine. She actually wants it French polished, which we're not about to do. Since shellac is such a non-durable coating, we're not about to warranty it. We've talked her out of that and into using CV.

I know step one is to apply the finish as usual using gloss, but what products out there can I use to really make this stuff shine? I want it to look soaking wet. I was thinking of regular automotive polishing compounds (like 3M Finesse), or perhaps another commercial product. What do you recommend?

Forum Responses

(Finishing Forum)

From contributor R:

I would use an automotive urethane or polyester or both. The problem with polishing CV is there is a danger of going through a film layer and creating a halo effect that can only be removed by re-spraying. Also, on a high-build finish, you are flirting with the 5 mil disaster film thickness. If you have to re-spray, you're really rolling the dice. Build the finish with polyester, spray on a good heavy topcoat of 2k urethane. Wet sand using 3m microfinishing film and buff out with automotive compounds and a lamb's wool pad.

From contributor S:

Buffing out finishes is something I do a lot. You want to start with sandpaper. I start with 800 wet, then 1200, then 1500, then 2000 grit. I then go to rubbing compounds. I use Mohawk Level 2 - steps 1, 2, and 3. Polybuff would come next if desired. C/V does fine, although I would rather use a post cat laq.

From contributor M:

It's a fairly simple process. Each sandpaper must remove the scratch pattern left by the previous grit of sandpaper. This pattern is repeated until you get to the finest grit sandpaper. By this time, your coating should be flat, smooth, and very easy to buff up to a super high gloss sheen with only polishing compounds. Because of the smoothness of the finely sanded coating, this smoothness will allow light to bounce off the finish, and reflect back in straight lines. The finer grit sandpapers mentioned in the previous post will make it easier to achieve the smoothest surface, which is what is needed to get that piano high gloss finish.

From contributor J:

Check out Target's website and download the coatings manual. Very good step by step for doing exactly what you are describing, complete with pictures. I think the process is very similar for solvent and water based products, with the only difference being lubricating agents. Good thing you talked them out of the French polish - that wouldn't make it past the first dinner party.

From contributor A:

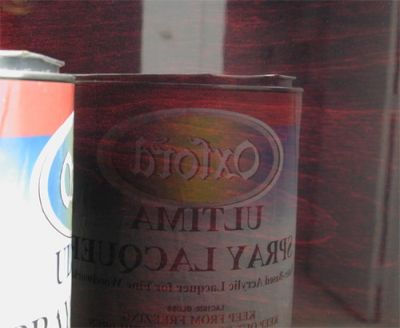

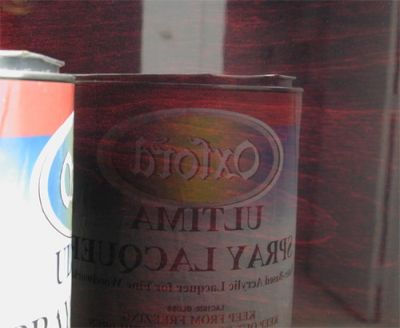

Just a picture of the last post mentioning the Target Coatings line. I don't think you can get any more high gloss in a lacquer. The key is multiple light coats and let it cure for 72 hours before buffing.

From the original questioner:

That's what I'm looking for! I'll check out their site.

From contributor B:

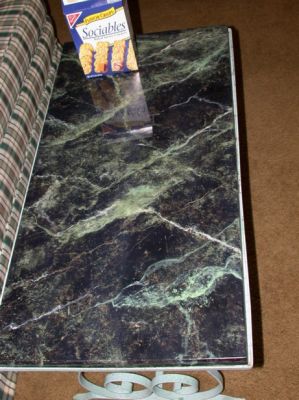

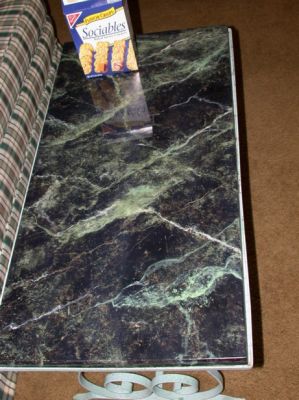

Here's a piece of oak that was marbleized, top coated with Target's USL, and rubbed out. The box reflection gives a pretty good illustration of the gloss you can achieve. This is 3 coats of USL, 4 days of curing before first 600 grit wet sand. Another 24 hrs of curing before sanding with Abralon pads up to 2000 grit. Followed by rubbing with DuPont automotive swirl mark remover, then wax.