Question

I am new to the cabinet making arena, although I have been woodworking forever. I am stumped on frameless versus face frame construction. Can someone explain the differences between the two?

Forum Responses

From contributor D:

A frameless cabinet is one that replaces the 3/4" thick solid wood face frame (on face frame cabinets) with edge banding. Or, put another way, when you build your box, instead of putting solid wood face frames on, put on edge tape/banding or thin wood strips no wider than the panels are thick.

We started out in face frame and made the switch a number of years ago and wouldn't go back to face frame for anything. We do traditional styles as well as modern, but it is all done frameless. The only difference to most customers is that the doors are closer together and there is more useable space inside. Hardware is more stable because it is fastened directly to the side of the cabinet, rather than to just the frame and the back. You will find arguments on both sides of the fence and you must determine what works for you.

One of the things I prefer about face frame cabinets is that on installation day, your alignment issues are much more succinct. Instead of having to line up a dozen door and drawer faces in an acceptable grid, you only have to make each one look good within its framed context. Bead and quirk face frames are especially forgiving. Here you can juxtapose a square corner to a round bead. About half of these jobs also have some distressing or glazing. It's hard to screw something up like this when you get so many chances to mask a problem.

With frameless, you build a box. There is a column of system holes (5mm in diameter, at 32mm on center) at the front of each side cabinet and a column of system holes near the back of the side panels. Then you can add doors or drawers using these system holes. The exact same box can be used for one big door, one door and a drawer, or all drawers. The box is built exactly the same. This is the beauty of full-access cabinetry.

One of the writers in this thread rightly said that to do frameless well requires a commitment to machines, whereas frame cabinets can be and are successfully built with far less expensive machines, but considerably more hands-on (most expensive) labor. I know very few companies who have made a commitment in the direction of frameless who ever looked back, and most lean toward it in a mix of frame and frameless if they have made the machine investment. I have written a lot of articles on the subject - search the archives on this site for "Elvrum". In addition you could look up the True32 site for a method that certainly works.

Jon Elvrum, forum technical advisor

Face frames almost double the material and labor costs, though. I am slowly making the transition by selling frameless to those that I know are using pulls. A couple of sample cabinets of each type could help selling frameless, too. I really believe that once the public sees that a frameless cabinet gives them more flexibility with no added cost, it will begin to take. Here, the folks are stuck on "traditional". But they aren't stupid, so I think frameless will fly, someday. I won't stop my face frame production, though. The change has to be made slowly and very carefully. If handled right, the changeover could very well mean a much more successful operation. The big obstacle for me is buying an edgebander that costs more than all my other machines combined.

I'm in business to make money, but want the customer happy, too. I'm sold on frameless, but my reputation can't be risked by bucking the mindset here, at least not right off.

Once a frameless kitchen gets past basic boxes in a mundane kitchen, many design obstacles are resolved by installation of some form of face frame, a "design-flaw" in esoteric lingo.

Let's make it simple - take either crown moulding or under-cabinet lighting. Why do both of these fairly typical items require some form of finished framing to properly install in most frameless kitchens?

For the record, I've been involved in frameless for some time, and by no means am I bashing frameless cabinetry. It's just not the holy grail that some people seem to believe.

I'm in the Southeast, and these folks tend to be very traditional and proud of their southern heritage, which I find strong on opinion and particularly reluctant to change, relative to many other geographical areas of the country. I feel qualified to make this observation since I have had the opportunity to live all over these great United States in the 32 years of my adult life.

The term "frameless" appears to many that they are getting less, or a weaker cabinet because of the thin banding used to replace the thick solid wood frame. One of the greatest obstacles is trying to sell PB core melamine, which I definitely prefer as a box material, especially since I have been building frameless cabinets and have learned how to machine this product to remove any and all of what I considered to be the substrate's weaknesses. The unequalled durability (and beauty, in my opinion) of melamine, coupled with the fact that it requires no finishing, makes it a bonus for myself, and my customers.

Having them believe that is problematic. I simply have a couple of sample panels handy, one plywood pre-finished with a conversion varnish and one of PB core melamine. Both clear-coated and edge-banded all around. I ask them to scrape across each panel with the back side of the point of my trusty pocket knife and they get to witness how the melamine surface doesn’t scratch nearly as easily as the clear-coated veneer. They pick up the panels and they like the increased weight of the PB melamine also. Remember that the edges of both are banded so as not to cloud their judgment with the sight of the PB (or the veneer core, for that matter). I make it a point to use a “less than attractive” figure pattern on my veneer sample, since that is what they can expect (arbitrary and unselected shop grade veneer) if I were to use real veneer as a box interior in solid door fronted cabinets.

I generally use white melamine for budget-minded customers, or utility type cabinets, or for those that just prefer a white interior. Hard rock maple melamine is used for most of my kitchen and bath cabinets, at a higher price. I still will use veneer core ply (at an even higher price), but I believe it is an inferior product to melamine for general cabinet construction, both to me as a builder and to the customer. If the box construction is engineered to remove the likelihood of breakage during manufacturing and shipment, and so long as the cabinets are installed so as not to allow the typical problems associated to water infiltration to the PB substrate, PB core products will last as long as any veneer core plywood and the finish will certainly remain consistently beautiful, long beyond the finish applied to a wood surface, given the same amount of abuse to each, in the course of typical kitchen and bath cabinetry use.

The most effective way to sell these cabinets here is to have a showroom or at least a decent sample run of each, of the same general design (same door and end panel material, similar moldings, and the same finish) and let the customers see and feel the differences. I, as many do, call my frameless line of cabinets "full access" to overcome the simple but powerful description that often turns off my (shall we say, less than progressive) customer base.

Building them cheaper… Well, I thought so, until I considered the cost of the Euro leg levelers and the wall cabinet suspension blocks that I find indispensable for assisting the installation of the more difficult to install frameless boxes. And the edge banding does cost something, too. I use more (some specialized) moldings for my frameless jobs that I wouldn’t necessarily use with framed cabinets. As mentioned, the machinery that is required to produce frameless cabinets productively will have to figure into your overhead and that certainly adds to the cost of producing each and every frameless cabinet.

Using peg board as a template might work for the occasional small job, but as you expand your frameless work you will undoubtedly want to add a line boring machine, which will tremendously increase your production level. I use a system that produces accurate 5mm system holes (provided the panels are square) but I still have to punch them one at a time. I can’t keep doing that and still compete with those that are using the proper equipment. Same goes for my Powermatic 66 saw and Excalibur sliding fence. It’s reasonably accurate (the way I do it), but it’s still much slower and less accurate than what a decent slider or vertical saw will produce. Yes, we all can produce frameless cabinets, but without the proper (read: expensive) equipment to do it productively, we stifle our potential for profit and growth.

Contributor U, there are no less than half a dozen ways to eliminate handles or pulls on a frameless cabinet. Like I said, face frame has its place: beaded inset.

Beyond that, frameless cabinetry and the 32mm system offer more flexibility in design and installation. This is not my opinion - it is a fact. We build very high-end kitchens and built-in wall units (more of the latter), VC ply and hardwood only, granite or solid surface tops, no melamine or laminate ever. Even our beaded inset incorporates 32mm hardware and construction techniques.

To the original questioner: If you are new to the cabinetmaking arena, and hope to have a profitable future in it, jump headfirst into frameless cabinetry. Read "True 32", do some homework and you will understand that it is the present and future of this trade.

Crown attached to the top rail of the walls, with lighting concealed behind the recess of the lower rail, attached directly to the bottom of the wall cabinet.

Frameless requires some type of frame stock to be mounted on top of the wall cabinets in order to attach the typical crown. Or a more expensive crown with an integral frame member machined into the crown is required.

There is no "built-in" light rail for frameless, as is the case with face frame cabinetry. An add-on light rail is required. This isn't to say that face frame installations do not utilize an add-on light rail, it's just not always required, nor does it have to be nearly as large in face frame installations.

Again, I'm not beating up on frameless cabinetry. I've been a proponent for longer than I care to remember. I am merely pointing out the need for caution in making any switch in methods, and the absurdity of absolute truths substantiated with blanket condemnations like "design flaws".

Jon Elvrum, forum technical advisor

It's not necessarily that one is better than the other; it's more that we all make a choice as to which of these vastly different methods fits our personality/manufacturing goals/life goals/etc. I have a frameless shop but am sitting in my office now typing this post, surrounded by about 30' of the most beautifully done face frame cabs I have ever seen! Truth is, the workmanship is better than some of the things I have done!

I use maple melamine too, almost exclusively. White once in a while, and veneer ply even less. I've been using an MDF core and don't bother to band the top edges. But I've come across a good price on PBC maple melamine that I will band. I use Fastedge, and yes, it's expensive ($150 for 250'). But it's quick, easy, and the only bander I have is a $15 Black & Decker iron. No trouble selling melamine here, especially the attractive maple.

I was talking to a builder today and he prefers frames because he thinks the frame adds appeal. Several have that opinion. As for me, I think they both look great. To get that look in frameless (fluted pieces, for example) you toss out the term "full access", though since those pieces are more or less fillers, don't you? Nonetheless, I've seen some great looking cabinets in frame and full access. I was once advised not to turn from doing frames if that is where my reputation and strengths are. Dabble with frameless, maybe in a utility cabinet line, and see what happens.

In the end, it is a system and a tool for building a cabinet. If you understand it well, it just makes sense. Years ago, when we didn't know anything about frameless and could not find anyone who did, we had Jon Elvrum come in and do a seminar with several of the area cabinetmakers. That got it started in this area and many of the local cabinetmakers have taken it much farther than I have. Learn all you can about both directions and then make the choice that's right for you.

The first place you will see this is in large institutional projects. The next place you will see it is when the guys that used to do that work come into *your* market.

Last year, China had one car for every fifty people. If you wanted to get a set of blueprints to an inner province six years ago, it was on horseback. They didn't exactly have UPS or Bucky's Messenger Service. Today they have the internet and the will to become the best capitalists that capitalism has ever seen.

The machinery guys would have you believe you can only compete if your technology is current. If that is your only market advantage, it will only last until someone else improves on the technology. The future for American cabinetmakers is high-quality work and high-quality service. High-quality work will only be an admission ticket to the job. The success part will come when the customer evaluates their experience with you.

Think back a few years and remember what the major box manufacturers produced - limited lines with a few finishes. They didn't get into Shaker or glazing, for instance, because they hoped it would sell. The big boys got in because Shaker and glazing caught fire with the custom shops, then grew to get the attention of the semi-custom manufacturers, finally followed by mass appeal. Looked at a Merrilat Catalog lately?

By the way, if the big box stores ever learn to sell better designs, they'll be a real force to be reckoned with in the higher style arena as well. The factories are now putting representatives into the stores on select days, and eventually that strategy will pay off.

In my opinion, the distinction you are attempting to draw is not there. This is not a frame versus frameless issue at all; it is a mass-production versus build-to-order (job shop) issue. Although your modular correlation at first blush would appear to make the distinction possible, it really has no relevance towards the quality of workmanship or the quality of the materials. Mass-produced products can only be mass-produced if a single item can be used in many locations or in many differing settings. Although my company builds frameless cabinetry exclusively, it is built to order, and built to fit only one home (although many of the components could theoretically be used in another location, the chances of that being the case based on door style, finish, and configuration are not really any better than your typical face frame cabinet).

We do primarily high-end residential cabinetry, and although that term has been debated several times on this and other forums, we manufacture frameless cabinetry for multi-million dollar homes. Last year we completed the cabinetry in the largest residence in Tennessee (32,000 square feet). This was a seven million dollar home, and regardless of what some might attempt to call it, I call that “high end”. In my market, I am not at all worried about the imported cabinetry from low labor countries, but I can absolutely guarantee you that many of the “high-end” face frame manufacturers are wondering why we are getting so many of their jobs. Maybe the question should be posed to all the frame guys out there: are you paying attention to what is going on with the stapled and screwed, taped particleboard manufacturers in your area? They may be your toughest competitors in the next few years, no matter what clever name you try to hang on them.

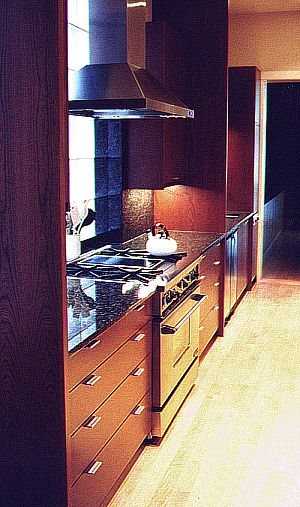

PS: Just a little illustration of our stapled and screwed, taped particleboard cabinetry.

China is a major issue - stroll through any Target, K-mart, Wal-Mart or Sears. They are currently entering our market virtually unimpeded and the long term view is that, without a national response, they will some day win. We as a country appear to have no stomach for this struggle, and the present administration - like their predecessors - are more interested in selling what we make there (in China) than in seeing what damage to US manufacturing has been done by the trade policies of the last 20+ years.

The advantage we still retain is that residential cabinetry is still pretty much *local* business, and still difficult to serve with a menu of customization options from far away. The place they have a chance at first is high-volume activity. The good news for the American cabinet making company is that there are not lots of large contract constructions going on anywhere in the US. If there were, we would suffer greatly, because when the prevailing wage is $6-10 per day, and the machine capability is comparable to what we have, the rules of economy slam us in the gut with a pervasive perception we cannot compete. The reason why our industry is not yet beset with problems is, in my view, in keeping the customer convinced that they have some design control, while leading them through a pre-developed process of choices that suit the actual builder of the boxes. Reward those who choose to select from the seller's system and penalize by pricing the few customers who ask a manufacturer to step way outside his comfort box.

Because the cache of custom permeates the market expectation, it still remains difficult for a foreign based manufacturer to mount an effective effort to compete. Because all of you work differently, it is hard for the off-shore manufacturer to enter the market, which does not mean he won't show up in markets that are receptive to their effort. As they become entrenched, they will expand outward, and one day they will put up essentially assembly operations onshore and in a generation be perceived as US companies, at which time they can amalgamate their operations and, for all intents and purposes, be perceived to be US companies.

Look, for example, at the number of Japanese and German companies now manufacturing for domestic sale here in the US. Now look for an example of a Chinese company investing in a domestic plant to deliver goods made for this market built in an indigenous factory. I believe you'll look for a long time. The engagement in Chinese manufacture being solicited by generations of politicians and corporate managers has proved to be a huge net sum loss. The Carolina furniture industry, thanks almost entirely to offshore manufacturers - mostly Chinese - have seen 4 million feet of factory space abandoned in the last three years, coupled with direct Chinese sale into long established retail chains, effectively cutting out US companies from the process.

Friends, it is serious stuff - we need to manufacture here in the USA. What manufacturing sector will be left if there is a major war in the future? Everyone agrees that America's ability to manufacture was a pivotal issue in WWII and Korea. The smallest number of people in the industrial age are now employed here in manufacturing based jobs. Think about that as you make purchases in the market place. We will all be accountable for the choices we make.

Jon Elvrum, forum technical advisor

Those of us who build face frame cabinets use staple and screw construction, in most cases. We don't grind as much, but we spend the rest of the day sanding (and sanding is getting old fast).

I noticed the use of bumping in and out and up and down, which not only adds to the design, but adds to the cost in finished end charges, while at the same time makes the job a little easier to align door-gap-wise (no 20 foot flush run to line up) and further allows us to use only mouldings in 8' lengths, so we don't have to scarf joint mouldings.

I mention this because the only product we do see in that picture is Conestogas, but that's the beauty of frameless - the design is entirely up to us and how we master their catalog.

They do sell a knock down face frame line, but one thing I've always disliked about face frame when combining cabinets is where one seam inevitably butts another, it is open in plain daylight for the world to see, unlike frameless, where it's hidden somewhat between a door gap. It also draws your eye to an uneven reveal based on the standard opening reveals where the seamed stiles will have two possible different colored solid woods with a large seam running right down the middle.

If I were going to draw out a face frame job to get the same look, I'd opt to construct with dados using a CNC router and make cabinetry runs with a single face and the use of partitions. I build 80% frameless too, but have CNC to accomplish this in face frame, so if the cabinet snobs want to step up to the plate, they're not doing a whole lot more than using component boxes themselves unless they're making face frame in the method I've described, bumping cabinetry up and down and in and out on runs of more than 8'. The final product is what the customer sees and they do not care what way or what machines we've used to create it. I added this comment to show that if the system of long runs and combined cabinetry were to be used, there would be a greater difference and something to argue about.

As it sits now, based on the reason behind 32mm construction without dowels in the first place, hardware location. The greatest difference is that a face frame box has a face and the hardware attaches to that and its back, while a frameless box uses edgeband and has its hardware attach to the sides.

We build everything - paneled rooms, furniture, short run custom mouldings, and even frameless (gasp!) cabinets. The technology your company, among others, develops and markets is fascinating (witness the lights out European factories), but how do you address the needs of the non-cookie-cutter cabinetmaker? Are we doomed generalists, ill-fated romantics? Does the machinery marketer have any toys for us? Maybe a grumpy robot floor sweeper or a prima donna sander?

P.S. My beef with particleboard and hot melt tape is when it is used inappropriately in high moisture applications, like bathrooms and kitchens. I've seen a lot of ugly three-year-old melamine in my time.

What do you mean when you say "grind"? I've heard this before and can't for the life of me figure out why some people think that we staple-and-screwers have to grind down the screws. It just ain't so, Bro!

There are some cheap melamine products out there, but if the better products are used, there should be no water damage problems in 3, 4, 5 or 15 years. I've had this stuff sitting around with standing water inside (Zargen drawer box) with no water damage whatsoever. The quality of the product makes the difference.

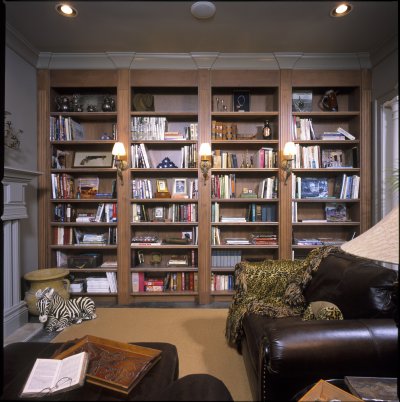

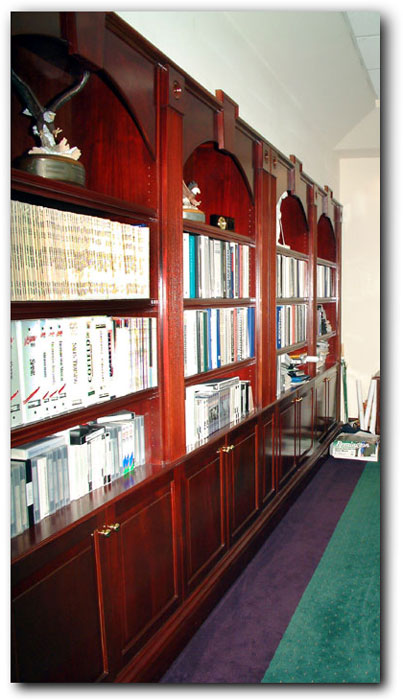

We do use both frameless and framed construction in our cabinetry. Mostly, we do frameless, but on bookcasing and other types of open cabinetry, we typically apply frames.

Frameless cases are perfect for cabinets with high utility - lots of drawers, things that pull out, lift up, etc. Most of the "active" hardware is easy to install in a frameless case. They're easy to clean, too.

As a frameless shop, I wonder why you frameless guys put a face frame on open bookcases? I don't and have only had one customer in three years say anything - I put a 1/2" mullion over the crack between cabs. I'm sure it's just personal taste and habit?

Several years back, I used to think the Euro style cabinetry was always commercial in appearance. I was really shocked to see what could actually be accomplished with a few applied mouldings and some nice looking doors.

Here's a photo showing a bookcase end cap on an island from one of our past jobs.

I remember when I asked exactly the same questions as you some three years ago. The journey since then has been the most exciting, rewarding and, yes, expensive, business journey of my life - what a roller-coaster! Worth every minute! Give yourself plenty of time in gathering your info and fasten your seat belt - you're in for a ride if you go for it.

There are a lot of very knowledgeable guys on this forum and others who have a wealth of info available on both frameless and face frame. We don't all always agree, but most of our discussions have been civil and respectful.

Also, if you haven't read the book "True32" yet, you should take a look at it.

Applied horizontal and/or decorative elements have long been used in frameless to allow you to accentuate the design. Just because it is not an integral face frame does not make it any less attractive or functional.

For laminate cases, we have integrated a "face frame" that was all sent as modular sections and installed along with the cases in the field for a pharmaceutical office.

Here are a couple of tips to get you started: For the frameless system to work, everything has to be square. *Square.* This is why panel saws are ideal. Boards seldom come from the factory square, so before cutting to size, you have to square at least one corner, so the parts you cut (on a table saw) come out square. A t-square jig and a router will make that operation reasonably quick.

Tip #2: Melamine panels tend to chip on one side on a table saw, but this only matters on shelves. You will only see the inside of the boxes when installed, so put the chip-free side on the inside. Shelves are a pain. There seem to be a lot of methods for cleaning up the cut, but none match a panel saw with scoring. I used to use an ATB blade, and feed very slowly, or cut 1/16 big and clean up on a shaper or use a router.

These methods are not efficient, but they are effective, without a large dollar outlay for tools. You can familiarize yourself with 32mm construction methods that way, and as you "get" the system, invest in more productive tools.

Tip #3: Tools are the key to efficiency. After you learn the basics of the system, you will see why. Then you can invest in the tools and make profits.

Maybe some others can give more tips. I am certainly not an expert on frameless. I got most of my information to start from a Blum pamphlet, and made up a lot of things along the way. So I'm sure I do plenty of things in ways that could be done better or more efficiently.

We still rabbet our box sides to accept the bottom and top, which is not generally the method of choice among frameless. But it helps during assembly, gives us a gluing surface, and makes putting the boxes together square easier. A lot of people butt the top and bottom into the sides, and use dowels or screws. I think just about any method you are comfortable with works.

"How are you covering the pocket screw slots?"

I don't need to - all the pocket holes are on the outside face of the end panels, and are either facing the wall or another cabinet. Keep in mind that I only use pocket holes on the units that I add a face frame to - the units pictured have no face frames.

"Have you done any cabinetry with a painted colonial look?"

Many times, but I don't have any photos. Just imagine the library units pictured earlier, painted.

The info I’ve received here since I posted my question has been excellent! I have downloaded from multiple sites, ordered multiple catalogs, ordered a few books and read about every thread on this site. I feel like I actually know what you folks are talking about now compared to just two weeks ago.

Since I can not afford a 20K machine to start, I have been looking at options for banding. Has anyone used an Edgeco Hand Held, Manual Hot Air Edge Bander Model AG-98 for pre-glued PVC, polyester, melamine, and wood veneer of up to 2" wide (50 mm)?

Just be aware that the pre-glued banding is not as permanent a bond as the glue pot machines (or glue cartridge such as Holzer). Having said that, I operated for years with hand applied banding with iron before I got my machine. It depends on your gross and throughput (how much product you get out the door). If your production is small, you can get along with hand banding for a while.

When you are ready for a machine you can find great used machines for usually around 1/2 the price. Just be aware that there is a lot of junk out there. I had a friend spend $3000 on a piece of complete junk. When you are ready I'm sure all of us here can guide you down the right path to a good machine.

I will say if you are serious about frameless and want to increase your business, don't hesitate to take the plunge and spend some money on new (preferably) or good used machines - assuming your business plan makes sense, of course.

To the original questioner: Tools are only one issue. The other issue is square footage. If you can’t set up a flow for manufacturing, you will have a hard time reaching your full manufacturing potential. And you’ll have to work on Fridays while some of us are out playing golf.

Editor's Note: Colonial Saw (website) sells and supports Striebig vertical panel saws and Lamello joinery systems.