Question

I have a 10" sliding comp. dual bevel miter saw and 5 1/4 crown. Can I lay it flat and bevel it at 45 to do an inside corner? Lets say: 90 inside corner, left piece, crown on right (bottom up) right 45 to get it the same as when I use the jig (it won't fit in).

Forum Responses

(Architectural Woodworking Forum)

From contributor L:

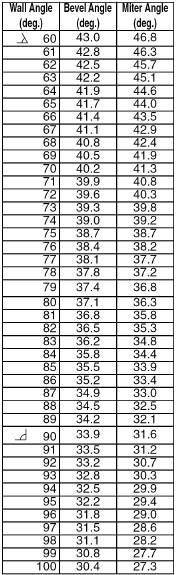

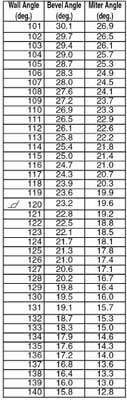

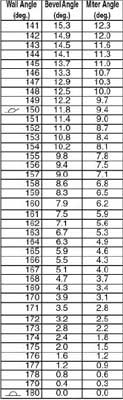

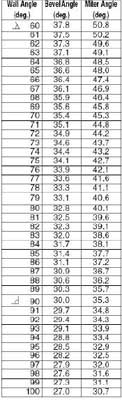

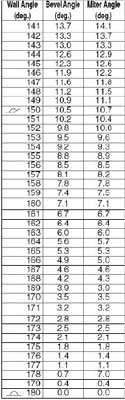

No, you need to set the saw up so that it will mimic you cutting the crown in the upright position. Most saws will have special marks on them for cutting crown flat. Usually it is a circle or a triangle. You also need to know if the crown is a 45º-45º or a 38º-52º to use the symbols. You would set the bevel and the mitre angle to read either triangles or circles. Then cut the crown.

38-52 a

38-52 b

38-52 c

45-45 a

45-45 b

45-45 c

I also had a Makita dual bevel for years. I had no problem attaching accessory wooden fences to that saw and used it happily, with great accuracy for a long time, cutting crown In-Position. The only time I cut on-the-flat is when the crown is too tall to cut in-position, otherwise, I can cut more than twice as fast and with much better accuracy in-position, running round 87 degree and 92 degree corners, changing spring angles in mid- stream while installing crown on kitchen cabinets where the doors vary 1/4-3/8 in. from the ceilings, etc. and you have to rock the crown a little at each corner. All of that is easy to do in position.

When you do cut on-the-flat, the back being parallel to the front doesn't matter because it's the back that determines the spring angle, not the front. Yes, if you're measuring the spring angle from the front, you could be introducing an error if the front isn't parallel with the back. As Contributor L said, if the back is cupped, even a little, it'll throw off your compound angle cuts big time. There's a reason that crown was cut in-position for so many years, before compound miter saws.

Also, when you cut on the flat, outside corners are not always on the right, inside corners are not always on the left. When compound miter saws first came out, they beveled in only one direction - just like radial arm saws (which is where the design originated). You had to flip the molding to cut the opposite angle. Flipping the molding is still the best method for cutting on the flat because each time you flip the bevel on the saw you introduce even more error: the bevel gauge on a miter saw is not nearly as accurate as the miter gauge - just look at the difference in the radius of each gauge and you'll know what I mean.

It's tough to dial in most bevel gauges to even one degree of accuracy, let alone 1/2 degree. Most of us still flip the material if the room size allows it. That means that sometimes the bottom of the molding is against the fence, sometimes the top. I always make my first cut with the bottom against the fence, if there's a right-hand inside corner or a left-hand outside corner. That way when I flip the material to make the second cut, I'm always guiding the saw blade and cutting to a measurement mark - measurement marks are always on the bottom of the molding (unless you're running crown up a sloped ceiling).

They would be under cut or over-cut causing a guessing game to which side to hold flat. If under-cut you would have gap at top and bottom against fence and base. If over-cut the piece would rock up and down 1/4". You should use whatever method suites you best. To most laying crown flat only needs to be done if crown is very large or miter saw can't larger crowns in normal position.