Floating Bookshelves Without Brackets

Other Versions

Spanish

Creative ideas for supporting shelves. February 28, 2004

Question

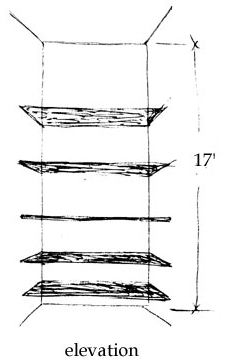

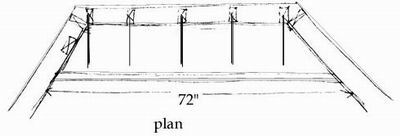

I'm an architectural woodworker in the Seattle area. A customer wants a set of bookshelves installed that float across a 6 foot span without brackets. I want to prefab and finish all I can in the shop out of two layers of 3/4 ply and a solid 1-1/2" front edge and attach them without using any visible fasteners or supports. The first problem is there is no framing to hang from on the right side and the left side is a bit of a mystery. Cutting into the drywall is not an option because there's a faux finish. So I've decided to try to utilize the back wall only and hang from the five studs using some 1/2" threaded rod epoxied into the shelves. Has anybody ever tried something like this?

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor B:

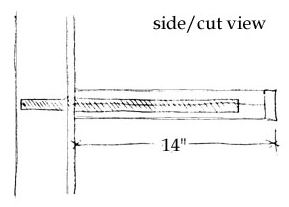

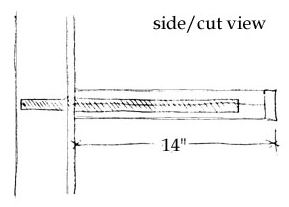

I did a fair amount of this during my 10 years working in Italy. There were many requests for blind floating shelves. Here in the States (we work in the Washington, DC area), I did a job where we attached 4" thick x 120" long x 14" deep mahogany shelves to a masonry wall using 3/4" allthread epoxied into the wall. The wall was about 18" deep, as I recall. We went about 8" into the masonry and left about 10" coming out into the room. It worked out great. In your case, if the studs are only 3-1/2", you don't have much to go into. Maybe someone else knows the ratio of how much rod should be in the hole to support the amount sticking out. You may want to consider making a 1-1/2" thick torsion box, skinned with 1/4" on both sides. If you plan it right and position the interior frame such that it receives the 1/2" allthread, i.e., lines up with the studs in the wall, it will be a bit lighter and that would also help.

From contributor H:

Piece of cake. On the sides and back, screw a 1/2" wide by 3/4" deep runner for each shelf. Dado out a groove in the side and back of the shelf. Slide it on the runners, put a screw in the back to hold the shelf to the runner, and you're done.

From contributor B:

If there is nothing to secure the 1/2" x 3/4" runners on the sides, then the runner on the back is not sufficient. In addition, this method can cause problems if the two walls on the sides are not square to the back wall and/or are not parallel to each other.

From the original questioner:

Contributor B, sounds like we're on the same page. I like the idea of the torsion box, however the 3/4 material I need to use is in the shop ready to cut. You've got me a little concerned whether bite back through studs is enough. My latest idea is to dado 1/4 x 1/2 out of each layer to form the hole for the allthread, then dry fit and check for sag. Maybe then I could bend the allthread up a little if needed.

From contributor B:

Maybe a combination of the two ideas would work. The runners on the sides attached to whatever you can find, even some construction adhesive and some plugs, might be enough to help minimize the sag.

From the original questioner:

Contributor H, going in through the sides is not an option because there's no stud backing on the right side to screw into. The span is also 6 feet, so it's probably going to sag when there's a bunch of books on it. That'd be a great way to go if a torsion box was used.

I think you guys are both right in that something needs to lock the two ends of the shelves into the sidewalls or they're going to give a little under weight and screw up that fancy paint job. That was something I didn't think of until now.

From contributor P:

Use a toggler in the side walls. They are 125 lb pull in 1/2" sheetrock if my memory is right. They are not toggle bolts - they use a 1/4-20 screw into a steel plate and that plate has two cable tie-like straps that hold it into the wall. I think they would be a great anchor in the side wall, and with your 1/2 or 3/4 rod in the back wall, you will have a solid system.

From contributor H:

Ever hear of drywall anchors? Those and a little construction cement will hold a moose. I know because I have hung quite a few shelves like the one pictured. I also scribe all my shelves when installing them. If you do not, then caulk the perimeter and you're done.

If you're worried about the front of the shelf sagging, then cut/dado in a 1" piece of T aluminum or steel. Cap or edgeband the shelf and you're all set.

The best way to do this is as contributor H mentioned - run a channel on the wall on the three sides and slot the shelves to fit over them. As the other posts suggested, toggle bolts and glue will hold up anything less than a moose. The main weight is supported along the back, so the side cleats will easily support the rest. If in doubt, do a mockup - it will take a few hours and you'll have peace of mind and it will still be a lot faster in the long run.

From the original questioner:

Seems like a dead heat - those in the channel/cleat camp versus those in the support bolt camp. Sounds like a mockup is in order.

Suppose I should be getting this done now. Too bad, because this postulating happens to be more interesting than the actual work. But then if we didn't do the work....

From contributor T:

I've hung hundreds, if not thousands, by the channel/cleat method with nary a call back. A couple of things to keep in mind:

1. Ensure that you cut the channel/dado deep enough to scribe the shelves to the walls without interfering with the cleat.

2. Use a hardwood to make your cleat. Softwoods have a tendency to compress and will eventually sag (this isn't so important when you are putting the shelves between walls but it really makes a difference when they have no side walls to support them).

3. Make your cleat as large as you can in both width and depth. (Chamfering the edges makes it much easier to slide the shelf onto the cleat.)

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor Z:

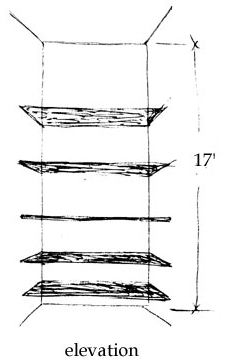

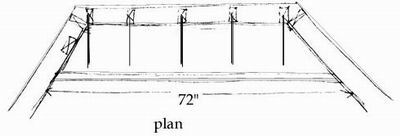

If you are going to put books on these shelves, drywall anchors might tear out. Why not put drywall anchors around the perimeter and run a vertical threaded rod down through the ceiling (securing to a joist above), through the shelf boards, and just through the bottom shelf? Use washers and nuts underneath each shelf to hold the shelves up. I'm currently doing this for a set of 8 foot shelves at my house and it looks very clean and industrial.