I'm trying to stiffen curved sheets of plywood along one edge. They are held in place at the ends and somewhat stable, but would movve with a lot of weight. I would really like to do the glueups without using other forms or heavy cauls and with a minimum of clamps.

I'm looking for a glue as well as a process. Any suggestions?

Thanks in advance,

Jim

From contributor Da

Not sure if i understand. Got a sketch?

From contributor Ji

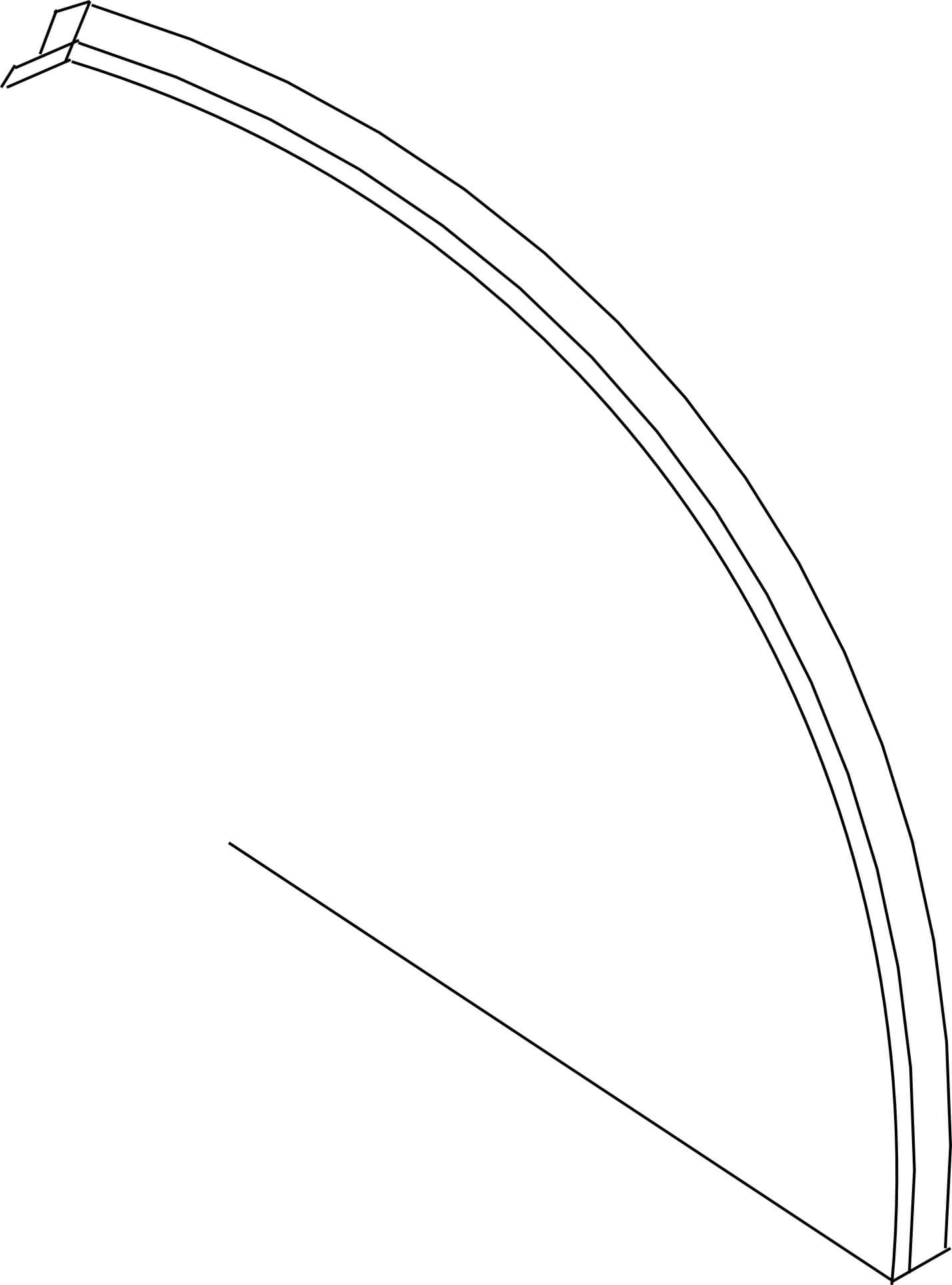

Not to scale, but here's a quick sketch. The plywood is 1/4" or thicker, the length might be 12' (with splices in the ply) and I'm thinking perhaps 6-10 plies, 1/4" thick, maybe 1 1/2 - 2 1/2" wide. I'd rather not screw it together to set the glue. I have a lot of flexibility about the finished appearance, and I might shape the rail (like, roundover or thumbnail). I mostly need it strong and to a certain extent stiff.

From contributor Da

JIm, well i think you re still going to have to clamp this whole thing together as you go. can you use spring clamps along the length and clamp them to the wider substrate? I ma still not fully clear from the sketch but it looks that you can ue the initial bent sheet as your basis to build up the edge. If you glue 1 or 2 layers at a time you should be ok. You can use titebond 3 or maybe even west system epoxy (gougeon brothers) to get it to work.

From contributor Da

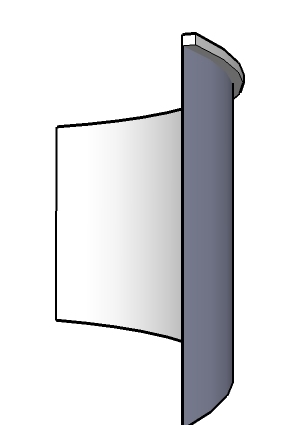

is this what you are meaning?

From contributor JI

Pretty much but my graphics program forgot to save a line ;?)

The plywood will be triangles. The bend needs reinforcing and the edge needs thickening.

Jim

From contributor Da

Just re-read the 12' part. wow, well if you can somehow get the surface bend to hold and still allow you to add layers of plywod then you should be able to make a kind of shell, you know? I think you may have to make some sort of a form to bend it around. I cant think of how to clamp it enough without cauls unless you staple one layer to the other like boatbuilding. A vac bag would be perfect too but you may not have those resources at hand.

http://www.westsystem.com/ss/

http://www.gougeon.com/

From contributor Da

Maybe this idea...

From contributor JI

I'm looking to do this on the fly. Looking at the blog about building the treehouse? Intense jig building. I'm trying to avoid that.

I can't put anything into a vacuum bag because it will already be erected, both ends tied in, and I can't get a bag around it.

The idea of spring clamps and epoxy may work, but it might be pretty runny while it's setting up, leaving a lot of mess to clean. I can power plane oand/or rout the edges, but if it gets on the panel it will be difficult.

Any other thoughts?

From contributor Ke

If I were you, I would consider the bagging some more. I have done numerous projects too big for a small crew to get into a bag. I lay the material onto the bottom half of the bag, while gluing the layers, then seal the top half down with two sided carpet tape, and some heavy calk like butyl.

Epoxy has the bridging properties, if you thicken it with something like colloidal silica, to about as thick as latex paint or catsup.

When you have the form outside the bag, it can be quite simple. it only has to be strong enough to support the resistance to the bend. All the pressure is inside the bag.

While I have three pumps, a while back, i did a test to see how much a sears shop vac would pull. I sandwiched my bath scales between two 1' squares, and was surprised to see 200 psf. That is about 1/10 what I can get with the other pumps, but epoxy only needs contact from both sides of the glue line.

I quit using West brand a long time ago. their price is about twice what I spend at Fiberglass Coatings Inc. down in FL. The one to one, comes thicker and is better for glue, than one formulated for glass or other fiber saturation.

From contributor JI

As I said, I can't use a bag. The plywood will be held on both ends as part of a built structure. Yes, bags have advantages, but in this situation I can't use one.

From contributor Mi

If you don't want to use a form, and can get to all sides, I've used strips of rubber inner tube for clamping curved laminations. Get the largest diameter tubes you can find and cut them into 1-2" wide strips. Then just wrap the strips around your laminations as you go, (like wrapping a bat handle or steering wheel). You'll still have to use a few clamps, though, at least at the ends.

From contributor Ch

Can you build the bag in place on your plywood frame

? Take that heavy vinyl your aunt used to upholster her chairs with and make your own bag folding it together and sealing it with duct tape. it works really well. No need to buy expensive vacuum bags.