Question

We hate the whole process of installation! Normally we hang the doors on the job site after all the cabinets are set and hung. The downfall to this is finding room to haul all the doors with blankets in between them to keep them from scratching. This also adds a lot of time on the job site hanging and adjusting. On the last kitchen we installed, we hung the doors in the shop, which gave us plenty more room in the trailer and made installation much quicker. The bad part was all the extra weight to carry and put on the walls. Is there a good solution?

Forum Responses

(Cabinetmaking Forum)

I used to hang doors on the job site after installation also, but found my install time to be much greater. I enjoy installing, as this is the last step of the job and close to payday, plus I get the chance to admire my work. Hanging doors with the correct hinge makes all the difference. Are you building face frame or frameless? Either way, Blum, Grass, Salice among others make hinges that fasten with one screw or are clip hinges, which make it easy to remove at the job site, either to carry in or to hang the cabinet. Hanging doors in the shop is the way to go. Another problem is making sure doors fit and you have all the doors with you, as there's nothing worse than leaving a door at the shop, an hour away.

I prefer to hang all doors and drawer fronts in the shop. Any discrepancies can be handled before getting an hour away. I snap the doors off the uppers before hanging, though. I just prefer to do everything possible before loading up because I'm the world's most forgetful fellow and I need all the crutches, idiot notes and reminders I can muster.

After they are hung, each one has to be adjusted and screwed to one another but no holding anything up while you are adjusting them.

We are a frameless shop and hang our doors and wrap before we load and install.

A friend of mine went to this Camar system or one similar to it. I think he told me that he had to buy one or two shapers to accommodate this simple hanging system. I would like to see it in action to see how it works. It would seem to me that a metal strip would hold the cabinet off the wall? I don't know how it works.

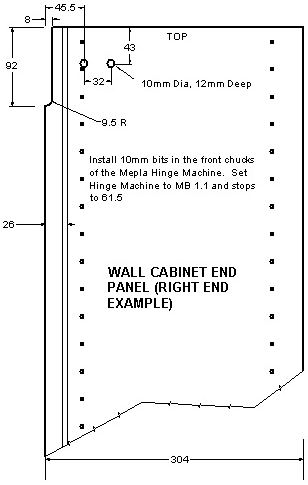

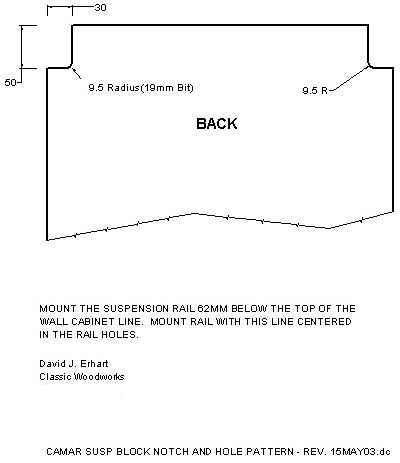

Fabrication is easy - set up router (mine is in my sliding table saw) to notch out small notch in top of upper back cab sides and a bit of a different notch in the backs - we use 1/4" backs.

You have to dado side panels of your cabs to fit the suspension blocks.

I'm sure Camar has drawings to show you how to install. I use the True32 methods so have received training through their company, which I recommend you look into.

I've exported a shop drawing from DeltaCad into .bmp form then converted it to a .jpg file with PhotoShop so that I could include an image with this post. By the way, DeltaCad is an inexpensive, super program for 2D drawings and has saved me much time and expense by experimenting with true dimensions on screen rather than wasting material in the shop. I work in metric. DeltaCad works with both metric and imperial dimensions.

I almost forgot to respond to the original question. I find it most efficient to do as much in the shop as possible and so I install all doors and drawers and make any necessary hinge adjustments while the cabinet is on the assembly table. Much easier to work at a comfortable height and make sure everything works and the reveals are tweaked here than in the install environment. The individual cabinets get wrapped with stretch wrap and loaded onto my trailer (as each one is completed) for transport to the job site. That effort frees up my small shop floor space progressively as I complete each cabinet assembly and when Iím done, everything is tucked neatly in the trailer ready for immediate movement to the install site, or can stay on the trailer for a day or several days until the job site is ready to receive them. Either way, I have cleared out my shop and can continue on with any remaining work or can start working on the next job, without delay.

At the job site, the cabinets are moved to the work area and the wrapping is removed, the doors and drawers are removed and set aside. The base cabinets are turned on their backs for quick installation of the leg levelers (the leg leveler skid plates have already been installed to the bottom of each base cabinet) and then all cabinets are installed as empty boxes. After installing the boxes, the drawers are slid into their cases and the doors are snapped into their proper locations. A typical kitchen takes about 10 minutes to complete the door/drawer install, since they have been fully adjusted in the shop beforehand. Applied end panels are screwed onto the end of cabinet runs, toe kicks are sized and snapped in place, knobs and/or pulls are added and the job is complete. Other advantages of installing the doors/drawers before transporting the cabinets include the obvious space savings during transport and itís near impossible to leave a stack of doors or drawers back at the shop. The stretch wrap holds all the fronts in place and helps protect them during the ride to the job site. The wrap also sticks one cabinet to another during transport, effectively making the whole lot of cabinets perform as a single unit - in other words, they don't slide and bang around or against one another during transportation.

I wish I could take credit for this (I think) brilliant process, but once again have True32 to thank for their ideas.