Making Sure the Budget Matches the Vision

Reprinted with permission from The Hardwood Council website.

How often does a client greet a painstakingly installed hardwood floor or staircase with the disappointed sigh, "It's not quite what I expected"? More often, probably, than most of us would like to admit.

Why?

You know home buyers want the warm personalities of North American hardwoods like ash, maple, birch, and poplar. Yet if you choose hardwood floors, cabinetry or woodwork simply by wood and by style, you could discover too late that your client was expecting the impossible.

Clients sometimes confuse quality, consistency and uniformity. Natural hardwood products are never as uniform as, say, wallpaper from a catalog; that's a major source of their charm. But "less uniform" doesn't mean "inconsistent," "lower quality" or "uncontrollable."

You can use accepted industry definitions -- grading systems -- to determine the degree of uniformity that the budget allows, to describe the look you and your client want, and then to hone in on the best way to achieve it. The time you take with your client, explaining wood's natural variations and how they relate to a budget, is time well spent.

Natural Variations, Unlimited Options

Diversity is the Soul of Solid Hardwoods

-- There are hundreds of North American hardwood species, each with distinct characteristics. There's no mistaking bold-grained oak for understated poplar, for instance, or resilient ash for hard-wearing maple.

-- Within each species, every tree is an individual. No two logs carry the same signature knots, burls or mineral streaks. Their lumbers harmonize, but they vary in color, grain and an unlimited range of natural details called character marks.

-- The features within any single log, from the center out to the bark, from end to end, are unpredictable. No two boards, even from the same log, are twins.

A log produces relatively few clear boards -- pieces free of character marks and other distinguishing features. So boards with no character marks rate the highest grades. Much of the remaining lumber offers good value, and may be perfect for your project. With a knowledge of hardwood product grading, you can take advantage of diversity, balance the variables and get consistent results.

Photos courtesy Fine Hardwood Veneer Association

Grading Systems: A Common Language

How You Can Get Solid Character on a Realistic Budget

How do you and your client know what you're getting if you don't specify "the best?" The answer is that there is no single "best" -- but there is a best solution for your project. To define that solution, it's helpful to understand the three hardwood grading standards that cover almost any combination of species, quality or application concern you're likely to encounter. They're similar in spirit to the familiar structural lumber standards.

-- Rules set by the National Hardwood Lumber Association (NHLA) prevail in grading hardwood lumber.

-- National Oak Flooring Manufacturers Association (NOFMA) rules cover flooring.

-- Architectural Woodwork Institute (AWI) standards deal with quality, materials, workmanship and installation of finished products, including cabinetry, stairways and rails, doors, window frames, chair rails and paneling.

Natural Value Without Uniformity

Hardwood character marks can add appeal for homeowners who appreciate natural materials.

-- They record a career in the forest: growth rings tally spring renewals; knots show where limbs have sprouted; bird pecks document forest life; mineral streaks register trace elements in water and soil.

-- They show that more of each tree harvested is used, responsibly, in lasting applications.

-- They extend the range of creative options for the homeowner, builder, architect, designer and woodworker.

NOFMA Standards

Appearance

The National Oak Flooring Manufacturers Association (NOFMA) grading system is appearance-based. Understanding NOFMA grades begins with the terms heartwood and sapwood, plain sawn and quarter sawn.

Heartwood, the oldest, densest, innermost section of the log, is often darker and richer in color than sapwood, which lies closest to the bark. The color difference may be so pronounced that heartwood and sapwood from the same species are marketed under separate names. Red pecan, for instance, is heartwood; the sapwood of the same tree is sold as white pecan.

Boards can be cut from a hardwood log in two principal directions: tangent to the annual rings (plainsawn or flatsawn), or radially, across the rings (quartersawn).

Arched or flame-shaped markings, evident in bold-grained hardwoods such as oak, characterize plainsawn wood, while quartersawn or "quartered" boards show a pattern of roughly parallel lines. Both have advantages in price, appearance and function, depending on application and species.

NOFMA Unfinished Oak

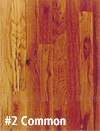

NOFMA divides unfinished strip oak flooring into four grades:

Clear

Select

No. 1 Common

No. 2 Common

Clear and select grades are further identified by sawing direction:

Clear Plain

Clear Quartered

Select Plain

Select Quartered

Length also plays a part in NOFMA terminology; 1 1/4" shorts, for instance, are 15-inch to 3-foot-long flooring strips. You may decide to request 1 1/4" shorts to reduce waste in bay windows and other irregular configurations.

Clear and Select

No.1 and No.2 Common

Pre-finished

NOFMA also maintains separate grading standards for pre-finished oak flooring:

-- Prime

-- Standard

-- Tavern

Since more than 90 percent of the hardwood flooring sold in the U.S. is oak, NOFMA grading dominates flooring. However, NOFMA also certifies maple, beech, birch and pecan flooring as first, second or third grade. First grade strips are practically free of character marks but permit natural variations in color. Second grade displays tight sound knots and other light character marks. Third grade flooring must merely provide a serviceable floor.

NHLA Grades

Usability

National Hardwood Lumber Association (NHLA) grades describe the amount of material in a board that a manufacturer of flooring, furniture, cabinetry or millwork will be able to use. In NHLA terms, FAS (firsts and seconds) describes higher, more valuable grades--long, wide, clear boards with little waste. Intermediate grades like Selects, No. 1 and No. 2 are assigned in descending order as size, percentage of clear lumber and value decline. In this system, about half of every log is non-appearance-grade, destined for applications like pallets and crates.

AWI Guidelines

Craftsmanship

The Architectural Woodwork Institute sets standards for appearance, engineering, fabrication, finishing and installation. Builders and architects need to be aware of only three AWI grades when specifying work to be done:

-- Premium

-- Custom

-- Economy

To illustrate, in custom grade millwork the gap between doors, drawers or panels and frames must be 1/16" or less. In premium grade work, the tolerance is 1/32"; in economy, 3/32" is acceptable.

Other variables that can be specified are the flatness of doors, flushness of joints, surface smoothness, hardware and construction techniques. Most architectural woodwork is custom grade, with premium grade reserved for special projects or focal points, and economy representing the minimum expectation of quality, workmanship, materials and installation.

Grading for Satisfaction

AWI grades also refer to character marks in finished products. Grade I, Grade II and Grade III limits, which set standards for clear surface area, vary by species.

When you understand the basics of grading, you can make informed decisions, clearly defining what your client can expect and your supplier can provide. Don't be intimidated by the fine details of terminology; the goal is to make the variables work for you. Your hardwood products source can help you clarify the details; just remember that grading is one way to ensure a match between the budget and the vision.

QuickTips

Availability and Value

The chart below shows the availability of North American hardwood species found most often in residential applications. Higher abundance generally implies lower cost, although some species may be more readily available in certain areas of the country.

*Includes Sap Gum, Basswood, Cottonwood, Hackberry, Hickory, Pecan, Birch, Beech, Tupelo, Elm, Walnut and other hardwoods.

Source: United States Department of Agriculture (USDA) Forest Service

Standard Sizes and Shapes

Half-inch flooring comes in standard widths of 1 1/2 and 2".

Unless a square edge is specified, mills ship flooring tongue-and-grooved.

Natural Characteristics

Solid hardwoods, like silks, leather and precious stones, look like they've been shaped by natural forces.

They often display:

-- Burls - Rounded growths on a tree which produce curling, ornamental patterns in lumber.

-- Knots - Hard, cylindrical regions marking locations of branches that have been encased by later growth of the tree.

-- Mineral streaks - Olive or grayish markings caused by such environmental factors as trace elements in water or soil.

-- Grain - The direction, size, appearance and quality of the fibers that give hardwoods strength and distinctive patterns.

-- Growth rings - Layers of wood added to a tree during a single growing season.

© 1999 The Hardwood Council

Reprinted with permission from The Hardwood Council website.