Question

Humidity is an important part of wood product design. Does anyone know what the average indoor humidity is for homes in the US? What effect does AC play if the home has a lot of indoor/outdoor traffic? How often do homes reach 70% humidity and above?

Forum Responses

(Architectural Woodworking Forum)

From contributor F:

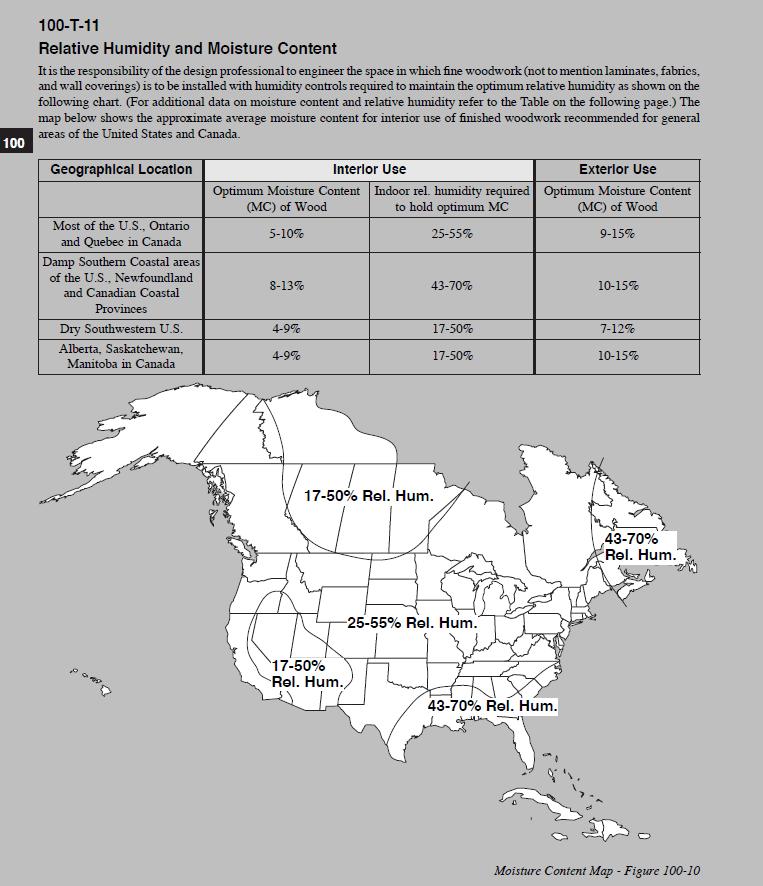

It depends a lot on your location. Michigan is severely different than Arizona, etc.

“What effect does AC play if the home has a lot of indoor/outdoor traffic?”

To the best of my knowledge, air conditioning dehumidifies along with reducing the temperature. Given that the chart below was based on data from the early 1900's, I think it's safe to assume that air conditioning was not a factor. So, it would seem that buildings with air conditioning would have humidity levels lower then shown on the chart.

“How often do homes reach 70% humidity and above?”

I would think humidity levels of 70% are extremely rare (unless there's an indoor pool/hot-tub or something similar). In my own personal (and limited) experience, when humidity levels approach 60%, other issues start to come in to play - mold, for instance.

Your question points indirectly to the issue of Equilibrium Moisture Content (EMC), which is used to predict the moisture content (MC) of wood when it acclimates to a given humidity level. The values below indicate the EMC of wood at various humidity levels, and when used with the chart, the change in MC for a given piece of wood can be accurately predicted, and this change in MC can also be used to accurately predict the dimensional change in the width of the piece of wood.

RH | MC

10%/2.5

20%/4.5

30%/5.2

40%/7.7

50%/9.2

60%/11.0

70%/13.1

80%/16.0

90%/20.5

If you search the Knowledge Base using the term "EMC humidity" (without the quotes), you'll find quite a bit of information on this topic. The paragraph below also offers some information regarding humidity levels. This was taken from an article written by myself and Gene Wengert. If we're lucky, Gene will weigh in with his comments as well. I don't know of anybody else with as deep a knowledge of this topic then Gene.

Homes in most of the U.S. that lack humidity control typically experience interior levels of humidity from 25% RH to 65% RH. This range of humidity will cause a 6% change in the MC of the wood. This change in MC will cause a 12" wide maple board to change 1/4". Exterior humidity levels range from 60% RH to 70% RH (lower in the SW, and higher near large bodies of water), and cause a 2% change in the MC of the wood. When material is installed that was delivered at an unacceptable MC, or the humidity range in the structure exceeds typical values, the amount of wood movement increases and can cause problems even in well design trim details. It's worth noting that panel material (plywood, MDF, composite materials) move at about 1/10th the rate of solid wood.

As for summer, AC plays havoc on the data because AC can extract moisture but is also lowers the ability for air to hold moisture. So air right before it leaves the duct would have around 100% humidity. I cannot get my head wrapped around how this plays into each other.

It plays absolute havoc with musical instruments, to the point that I refuse warranty coverage on mine unless the owner can keep it in the 40 to 70% area. A three foot wide 1/8th inch soundboard glued to the perimeter of a case can have sufficient change in width across the grain to buckle it in the summer and produce cracks in the winter.

A major frame and panel door manufacturer was having problems with parts fitting. They made parts in two different locations, and assembled in a third. They also had problems with the finished product. After two days or wrangling with this problem, using good data from the manufacturer on plant RH and MC of the wood, the consensus of the engineers and attendees was that the only solution was to decentralize the manufacturing into regional cells. One could not make parts in New Mexico, ship and assemble in Iowa, then ship the final product to Minnesota without having problems (over 5% failure).

In the conversation, almost everyone told tales of problems with solid wood problems when fabricated in one area and used in another. The problems always related to the EMC differences, and were always with solid wood.

This is what you are seeing with the wide statistical variation. This is also, by the way, a major reason for any movement away from solid woods to man-made panels and such. By the way, the door manufacturer determined that regional production was not going to happen, and they fell from being one of the top producers of such doors to closing the doors. The reason was unreliable quality, with joints opening, stiles warping, etc.

It is well to note that we (the general American public) will be unsatisfied when the RH drops much below 35 to 30% RH in the wintertime in our homes, due to the static electricity, dry nasal passages, etc. So, that sets the bottom limit for many homes. Also, the US Forest Service maps assume heating to 72 F, which today is not always done and which dries out the air. So, the dry values are just not that common. In the summertime, we tend to see mold growth (like in the bathroom) and dampness (like in the bedding) when the humidity gets much above 65% RH. Likewise, the cooling coils on an air conditioning act like a dehumidifier. So, summertime average humidity is seldom above 50% RH inside a home and in many locations are drier.

That having been said, and using the fact that shrinkage is more of a problem that swelling, we will target the lower MC range in millwork, cabinets, furniture and so on. You will find that 6.5% MC will be suitable for most of the USA. In the old days, some said 6 to 8 % MC and others said 6 to 9% MC. This still persists and it is this old value (when used in today's modern structures) that keeps my consulting business running - perhaps 75% of the manufacturing calls I get involve lumber and wood products that are at the wrong MC for their environment. Bottom line is that it is probably impossible moisture-wise to make one product that will perform perfectly in any location in the USA, Canada or the world.