Jigs for a Moulder

Examples of jigs and rigs that can help you run custom crown moulding on your moulder. April 21, 2011

Question

I've become pretty proficient at making crown with my W & H. It's a real joy to have the crown finally match my species. I haven't actually had the time to try anything other than crown, but I do run after base shoe and 3/4" quarter round a lot. It's usually not the best quality, nor does it match well. Is anybody doing either with your W & H and if so, any tips?

Forum Responses

(Cabinetmaking Forum)

From contributor J:

Though I haven't run those two profiles, I would suggest a vee shaped fixture attached to the bed of the machine to facilitate downward pressure from the feed rollers and capture the moulding in position as it travels through the machine. You may already incorporate such a fixture.

From contributor L:

Since the machine is open ended, you can get chatter on any profile no matter how small. The solution is to make it a closed end machine whenever you can. The other surefire method for nice moldings is to get the speed control setup. The 17ft/min is pretty quick and makes for moldings with good sized mill marks.

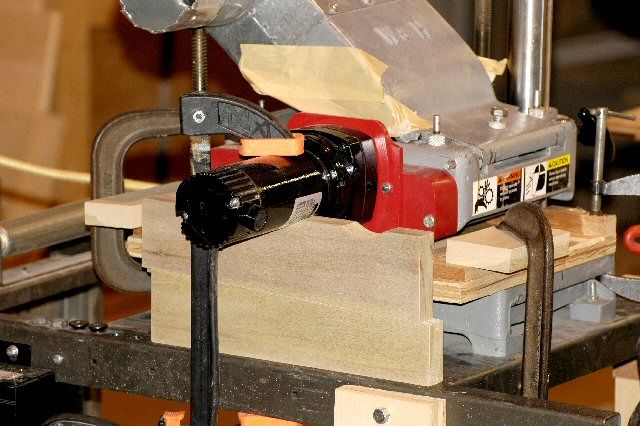

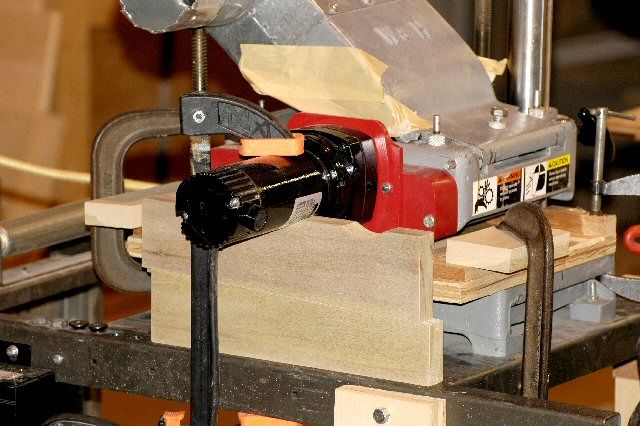

Here is the setup I use for making the machine a closed ended machine.

Click here for higher quality, full size image

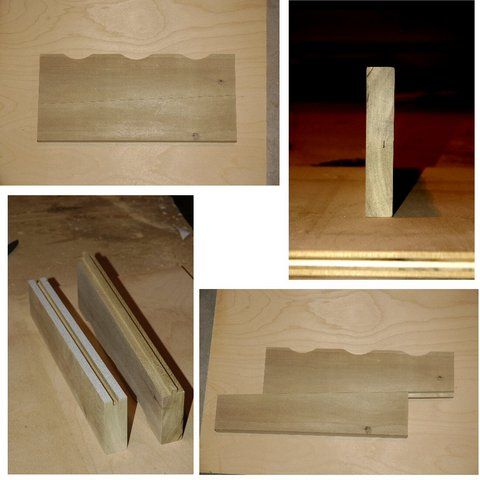

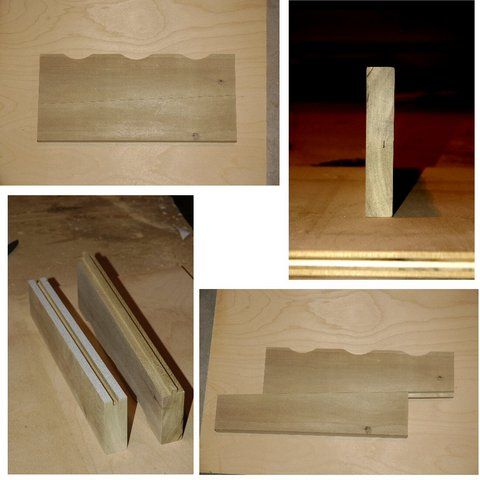

Here is a breakdown of the sliding stop.

Click here for higher quality, full size image

Images by Leo R Graywacz Jr., LRG WoodCrafting

From the original questioner:

Thanks. That's what I was looking for, contributor J. I knew my current setup for crown wouldn't work for me. Contributor L, several months ago when I got my machine I asked for help and you showed me your setup. I decided to try it without doing anything and quite honestly I don't get any chatter marks to speak of (hardly needs any sanding), but I'm only running it on about 3 and making multiple passes. I suspect you get by with less passes and I may still consider doing what you've done. Have you made any base shoe or quarter round?

From contributor L:

I do a 5" crown in one pass; only time I do a second pass is on the setup board. No, no quarter round. The smallest molding I do normally is a band molding that is 1 3/8" w and 5/8" thick. I still use the closed end setup and run it at about 5-7ft/min. Rub some 150 grit on it and you are set for finishing.

From contributor W:

I use mine to make the bracket feet on this cabinet, the drawer front, and the reeded pilaster. It also makes a 1/4" bead I use in beaded face frames. I've made arched casings on cabinets, elliptical casings on windows, replicated old mouldings, etc. I found you have to keep the knives sharp. I sharpen them on my Tormek sharpener and don't have to sand anything.

Click here for higher quality, full size image

From the original questioner:

That's gorgeous - thanks for sharing. What jig(s) do you use on your Tormek to sharpen your knives? I have a Tormek and am trying to figure out how you do it.

From contributor W

I do it by hand. I use the grinding wheel and grind the back of the knife, and if it fits, I'll use the leather strop. You can't grind the cutting edge, or you'll ruin the knife.