Material for Vacuum Pods or Cups

CNC owners discuss the materials they use to machine their own vacuum pods. August 3, 2009

Question

I will be routing my own suction pods/cups. I'm looking for material recommendations other than Bakelite? I would need the material to be wear resistant and easily machined.

Forum Responses

(CNC Forum)

From contributor M:

You might try using plastic. I have used scrap solid surface material such as Corian for vacuum devices. They are available and don't cost me anything, but they are generally simple devices used on either my matrix table on top of my bleeder board to elevate part.

From the original questioner:

Any particular type of plastic?

From contributor M:

As I mentioned, I have only used stuff like Corian, Gibraltar, etc. Itís easy to machine especially for custom applications. I did some aluminum stand offs as well, but didn't like those as much.

From the original questioner:

What do you think of using nylon?

From contributor A:

I just ran across King Starboard. I bet it would work great for this type of thing. Itís nowhere near as brittle as Corian, and though I haven't tried it yet, it feels like it would machine easier than nylon. Anyone else tried this?

From contributor M:

I still think that a laminated phenolic or something like Bakelite will perform better with the temperature and moisture ranges we all experience.

From contributor K:

I have made hundreds of pods out of solid phenolic material and they work well but are a tad brittle. I have used solid surface to re-top pods and it worked but I won't be doing that again. On the last go we made pods for two machines out of HDPE, it's just like Starboard. It machines nice and is very durable. It does have poor temperature and moisture ratings but no problems so far and we have been from 100 and humid to -10 and dry. I wanted to try PVC because it has better temperature properties but it's 2x the price of HDPE. Next time I will try the PVC but the HDPE is still working.

From contributor N:

I used "Garolite XX ". Itís easy to machine with carbide tooling. Like all Garolite, Grade XX is lighter than metals but dense and strong. It's a paper-based laminate with a phenolic resin binder that absorbs less moisture than Grade CE or LE Garolite. Itís good for use as a template board or for gasketing and gears.

From contributor I:

You can use any of the materials mentioned above and they will serve your needs well. However, one thing I will recommend is that you "surface" them before you cut your grooves for gasketing in the tops of them. That way you can guarantee they are uniform height and level.

From contributor W:

What about MDF and sealing them with conversion varnish? I intend to try that next time.

From contributor N:

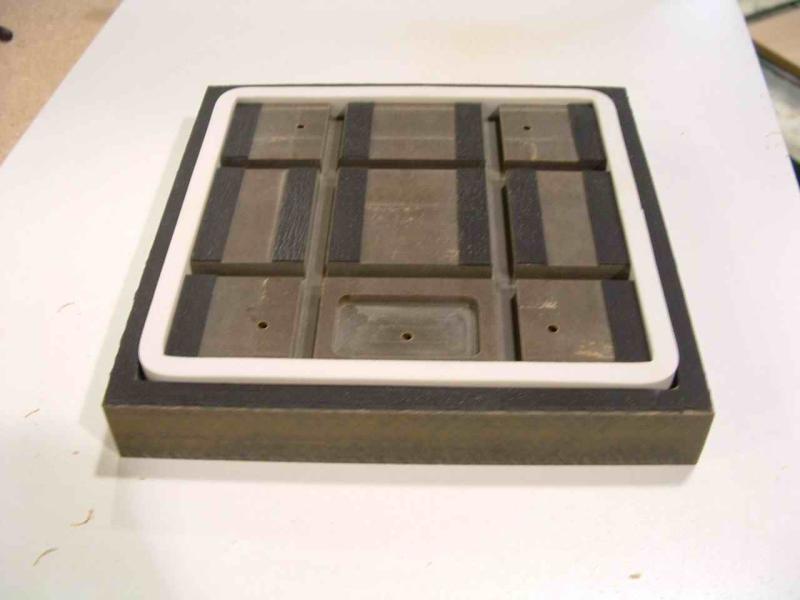

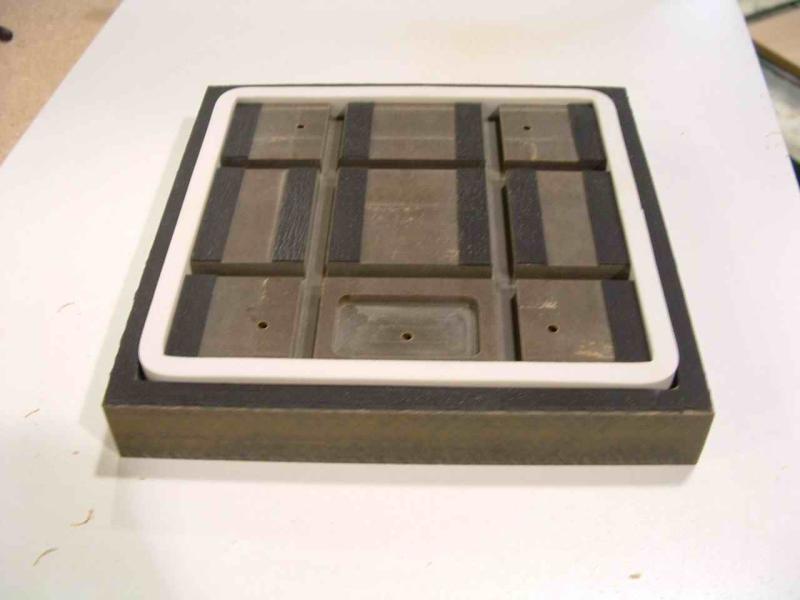

Below is a picture of a suction pod done with Gerolite.

Click here for higher quality, full size image