Mitered Door Joinery

Some cabinetmakers say mitered doors are just a bad idea, but others have tips for improving the joints. October 9, 2006

Question

I'm having problems with miters opening from outsourced doors. After finishing, most of the doors are opening up. So far, the company has agreed to replace these, but I'm in the middle of a problem and don't know what to do.

Forum Responses

(Cabinetmaking Forum)

From contributor A:

Never make, buy, or sell mitered doors ever again. They are junk and will always open up with humidity/temperature. The only way to get those joints to hold would be to do a really good epoxy joint in which the wood is now a composite. However, that would double the cost of the door. I refuse to use mitered doors.

From contributor J:

Contributor A said it bluntly, and I agree.

From contributor K:

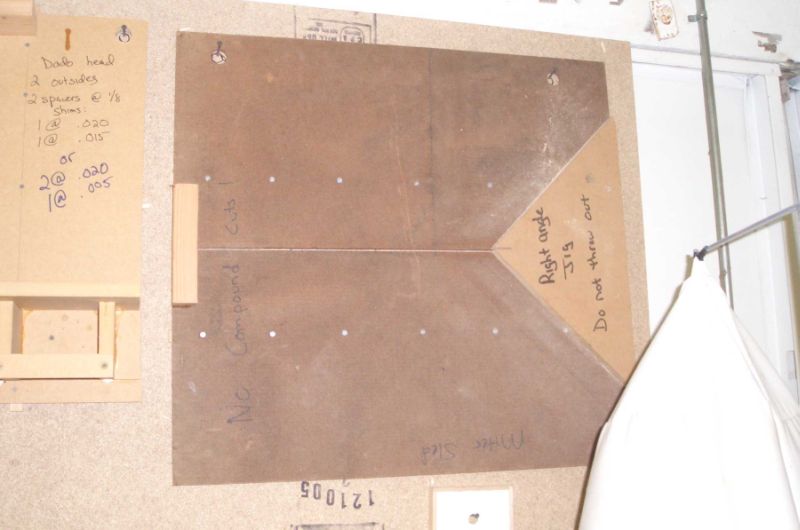

Use a floating tenon. Epoxy thickened with silica is not a bad idea, but

Titebond 2 has worked well for me. Below is a photo of how I cut them, but you can use a jig and router as well. I don't bother putting glue on the end grain, just the floating tenons and two mortises. Saves me the trouble of getting squeeze-out off the face and back.

Click here for full size image

From contributor K:

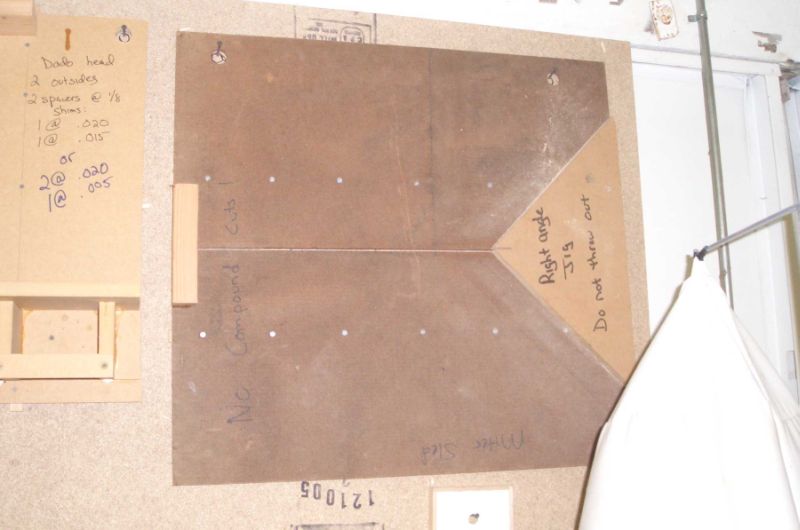

Also, excessive clamp pressure never makes up for a poorly cut joint. Use a repeatable jig to get perfect miters. It's worth the time to set up something that works perfectly. Below is a photo of one of the dedicated sleds I use for miter joints. I have a tweaking jig as well for a sander.

Click here for full size image

From contributor M:

I haven't used outsourced mitered doors, but I have made plenty of them. I use pocket screws to hold the corner together with glue. This works great unless you are dealing with a narrow rail and stile. I have done a few with floating panels, but my preferred is gluing in a plywood panel. You might be able to use a portable pocket screw jig for preventative maintenance on these doors you're having problems with.

From contributor H:

I have used outsourced mitre doors for years, in Montreal, Canada, where the summers are in the 90's and the winters are 30 below zero, and for the last two years in South Florida. Have not had any problems with joints opening up. Perhaps I was lucky enough to find the right suppliers (Miralis in Montreal and Custo Cabinet Doors in Lauderdale). Miralis used a floating tenon and finger jointed ends plus pinning on back. Here in Lauderdale I'm not sure of joint construction, but they do use a woodwelder and radio frequency for raised panel layups.

From contributor G:

"Never make, buy, or sell mitered doors again." Should we say the same for all miter joints? There are many applications where miter joints are used in cabinetmaking. Why are the doors to be avoided?

From the original questioner:

Thanks for all the replies and the pictures. At this time I'm halfway into a job from hell. Even if the door manufacturer replaces the doors, I don't think they will hold up. As far as not doing miter doors anymore, that is not a solution to the problem now.

From contributor I:

Regarding "Never make, buy, or sell mitered doors ever again."… That's a terrible statement to make. People have been using mitered joints forever. I have outsourced many mitered doors for my customers over the years and never had a complaint. If you purchase quality doors, you shouldn't have that problem. Many small companies produce doors inferior to larger reputable companies with years of experience. You get what you pay for.

From contributor J:

I've seen doors open up after a season of expansion and contraction and I've seen doors take 10 or 15 years to start to open up. Sometimes it's the humidity, sometimes it's how hard people shut the doors that causes joints to fail. I agree there are some good manufacturers of mitred doors, but I stopped using them, as I want to absolutely guarantee the products I sell and plan on passing the business to my kids. With mitred doors, I just always feel there's a risk involved. That's from my own experiences and jobs of others that I've seen.