P2P Origin Placement

Other Versions

Spanish

Best postitioning for running gables on a point-to-point router. March 14, 2004

Question

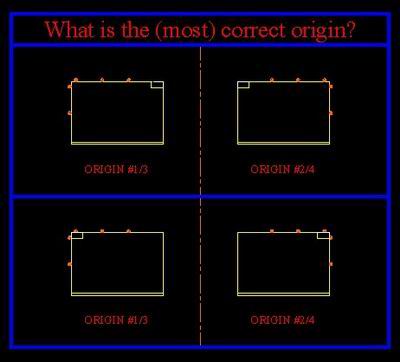

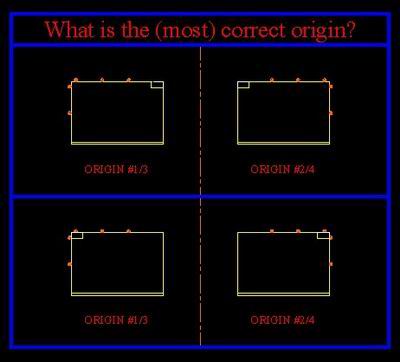

What is the consensus on origin positioning for running gables on a point to point router? There are two totally different schools of thought on this subject and I really need some definitive feedback.

Forum Responses

From Brian Personett, forum technical advisor:

We use three constant references in our system: bottom, front, left. Any part you machine will hit two of those, which will define your origin.

From the original questioner:

Please clarify, Brian. A 2D origin is 2 points… which 2? Which edges correspond with X and Y?

From Brian Personett, forum technical advisor:

For instance, your base side, using my Bottom, Front, Left method. The front edge would be the X axis, the bottom would be the Y axis. These parts would be mirrored, thus creating a left and a right.

Think of a cabinet in 3D. We use European construction methods, so the front and bottom are givens. I just arbitrarily chose the left, because I read left to right. If you think of your cabinet in 3D, every part will use two of those origins, thus giving you your origin points.

I think every origin is correct. On the Biesse Rover that I run, I usually use origin 1. Origin 2 is the mirror image of 1 as long as the piece is not over 46" long. If it is, I must use origin 4, which is also the mirror of 1. Origin 3 is the same as 1, just in a different location on the machine, and origin 4 is the mirror of 3, once again as long as the piece is not over 46". On the Biesse, you can do pendulum machining, meaning you can load at origin 1 or 2 and while the machine is routing that piece, you can load origin 3 or 4 and the machine will jump back and forth between the parts. The good part about this is that there is no stop time for loading material - the router is always going. I don't really know what you are asking about which origin is correct… they are all correct.

From the original questioner:

To clarify, I was not asking about machine origins or the benefits of 2D vs 3D. I am asking what the correct way is to originate a cabinet gable, from a direction of machining and runout point of view. I use 1 and 4 for obvious reasons, but what are your opinions as to how to place the work piece (in relation to taped edge, kick location, etc.)? Hope this is clearer.

Base/tall cabinets: bottom, rear. Rear because I want the groove for the backs to align perfectly with the top/bottom. Also, we use a "shadow reveal" at the front. In other words, our sides are slightly wider than the top/bottom, so they aren't flush at the front, but they are flush at the back.

Bottom because base cabinets are installed flush at the floor.

Wall cabinets: top, rear. Rear, same as above. Top because wall cabinets are usually installed flush at the top.

Many people run the toe kick notch away from the pins, so any variation in part sizing falls in the toe kick rather than the case, and on a wall end they reference the bottom edge and finish edge to the pins and set their parametrics up so any deviation happens in the space from the back of the panel to the face of the groove.

If you are sizing the parts on the machine with a router bit, the choice of which way to orient the parts is up to you. Since all of the boring will be done at the same time as the routing, the boring should be accurate. If the panels are sized before they are put on the machine, I would put the top edge of the panel against the stops. That way any inaccuracies are at the bottom of the cabinet, where they are less noticeable. One suggestion would be to start a convention that is always followed as to the orientation of the parts on the table. For example, you could make it the rule that parts are always located with the longest edge parallel to the x axis, and the top of the parts against the stops. This way the operators know which way the panel goes on the table as soon as they pick it up. Any parts that don't follow the convention could have a large bold note put on the shop drawing. Something like "not standard orientation." A small detail showing the proper orientation could also be put on the shop drawing, if this is necessary.