Pre-Finishing Cabinet Doors

Should you finish cabinet doors before or after you assemble them? Cabinetmakers and finishers discuss their processes. May 24, 2006

Question

I have always finished (stained) after assembly and opinions seem to vary concerning this and wood movement. My volume of cabinet doors is rising, so I thought it was good to check. For those that say pre-finish (stain), does that mean all the parts and if so, would this rule out a final pass through the drum sander? Time and efficiency are key here, so I would appreciate the benefit of real shop experience. Do you pre-finish just the panel, and what's an efficient way to then finish the frame?

Forum Responses

(Finishing Forum)

From contributor C:

I always stain and put a sealer coat on my panels before putting them in the frames. I make sure my panels don't stick above my frames so I can finish sand my frames without hitting the panel once glued together. I also stain the inside of my frames and the profile before installing

the panels so I won't be staining the part of the frame against the panel.

From contributor J:

I'm a one man shop, and I do everything I'm capable of in-house. As a one man shop I don't do a large volume so I don't know if my process will translate to a larger operation. I pre-stain and seal or prime my panels. Then I glue up the doors and run through the drum sander and follow with hand sanding. Then I'll stain and seal the rest of the door being careful to keep/wipe stain off the panel, so it doesn't affect the sealer. In the end you'll just have a couple extra coats of sealer/primer on the panel.

I do know not all shops do it this way, because I have seen doors over the years which have those pesky unfinished lines at the edges of the panel. Like I said I don't know if this is the most efficient way of doing doors, but it works for me. At least until I learn a better way.

From contributor P:

We make and finish all our doors too. I use "easement" cope and stick cutters to solve this problem. This allows us to get stain and or glaze in the panels behind the profiles of the rails and stiles. It works great, and it’s what most of the major cabinet companies do.

From contributor A:

We run a professional finishing shop and we spray and wipe our stain for door and panels from a number of cabinet manufacturers. When spray staining we shoot in the groves and it comes out fine.

Also, for high end jobs we often stain with a brush and wipe. This also wicks the stain into the groves well with nice results. Additionally we finish all the gable ends and other pieces of the kitchens at the same time prior to the assembly of the boxes.

From what I know of the finishing industry in this regard this is how things are done in most commercial finishing shops. Pre finishing panels can lead to damaged panels that then need to be repaired. This can be difficult and time consuming at best. To ovoid the lines that appear over time you should just make sure all the wood is properly dried and seasoned. I always test the wood for moisture content and don't warranty the finish against shrinkage of the panels.

From contributor M:

I build my doors then stain. I use a brush to work the stain into the panel edge. If you are finishing in the winter (humidity low) then you don't have much to worry about. You do need to be careful in the summer, though. Big production shops are climate controlled, including temperature and humidity. They either wipe or spray their doors after they are assembled. This is not to say that the 'finish before assembly' method is not a good one.

From contributor H:

So, by using this approach you basically shove the finish under the frame? What defines an easement cope and stick cutter? Also, could you tell me who makes them?

From contributor H:

Freeborne makes the ones we use. It does add a bit to the price of the cutters but it’s worth it. All of the cope and stick profiles Freeborne has can be ordered with the easement feature. This really works well glaze also.

From contributor L:

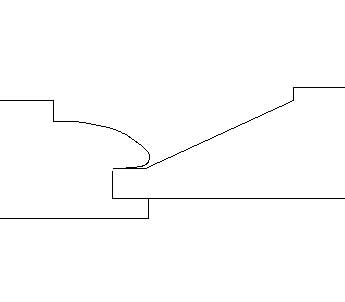

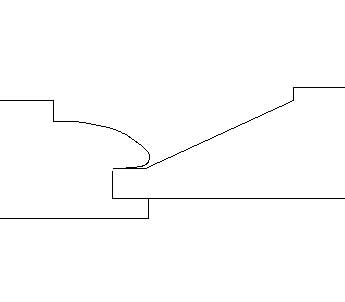

On the stick section of the cutter it has a rounded edge that is slightly above the panel. This allows stain to get under and also hides any unstained section of the panel as it moves seasonally.

From contributor B:

Here’s another solution - when you have a wiping stain applied, take an air hose and blow the stain under the edge on the panel. Blow all around until you're satisfied it's all covered. Then do your wipe off of stain. If you’re spraying spray only, then angle your spray to get under the edge if possible.