Question

I was wondering if anyone could give me an idea for a price of the kitchen I am working on. I realize this is dependent on region, etc but I am just trying to get an idea. The kitchen is red oak stained mocha brown, flat panel shaker doors and 40 inch uppers with 2 1/4" crown on top.

If you could give a price for the cabinets and how much this would maybe be to install I would greatly appreciate it. I know I undercharged and I don’t want to make that mistake again.

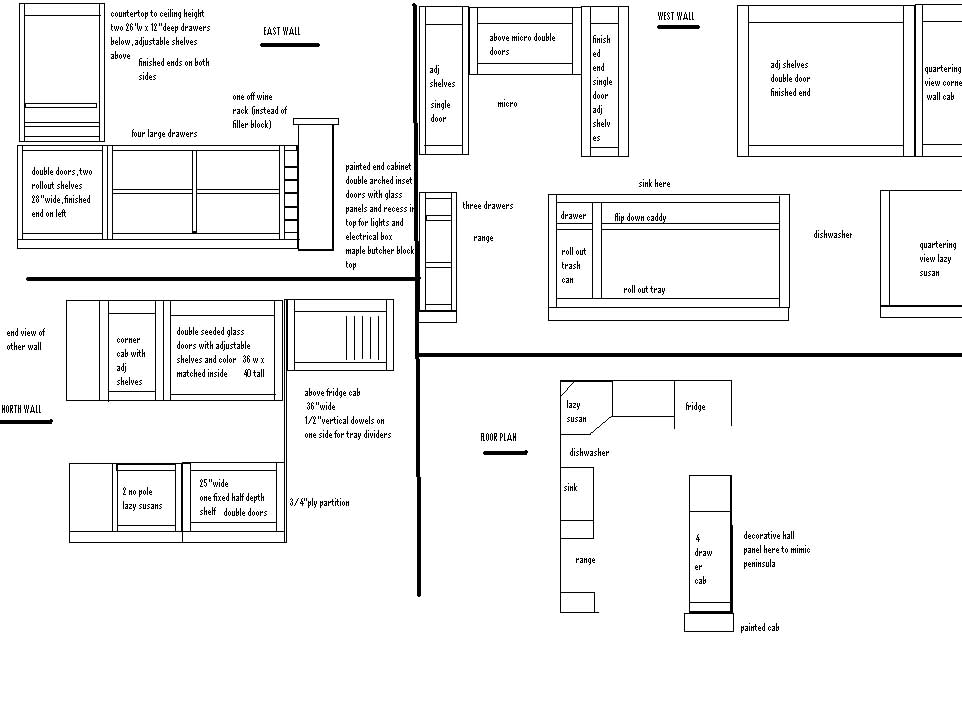

Here is a 2D picture. I am trying to learn sketch-up, but it’s coming slowly.

Forum Responses

(Cabinetmaking Forum)

From the original questioner:

I forgot to mention that they are 2" face frame cabs.

I think that it’s on the lower end of price because I used unfinished plywood, and built my own doors, drawer heads and drawer boxes. Both of which would have increased the material bill and decreased labor (therefore leading to a larger total bill and saving time). I will be outsourcing the doors next go around.

The customers are friends of mine and they gave me a chance to do this. The cabinets look great and we will be delivering shortly. I'm sure the price is low, but it is not really a loss to the small shop portion of the industry, because if it wasn't me building them, it would have been Kraftmaid or comparable. The last thing I want to do to get a job is cut anyone’s throat (especially my own).

I couldn't get a good look at your layout on my screen, but it seems like a smaller kitchen. For myself, I can say in general it would be difficult to do even a small kitchen for less than 15k installed.

If you take Contributor A's advice you will get a much better feel for your competition. Although it won't help you much in pricing your work, it can't hurt. Case in point, I'm just finishing up a kitchen now which cost just over 20k. My clients told me, after I gave them my bid, that the local lumberyard quoted them at about 2k less than what I quoted. That's a pretty small difference for the size of the job.

Which leaves me wondering, did I charge enough? I got the job built in the timeframe I planned on, used less materials than I budgeted for, will make a good amount of profit, and have already secured other work from the job. That makes it a pretty successful job right? But I can't help but feel that my prices shouldn't be that close to semi-custom cabinetry. So although knowing what the other guys charge doesn't help me figure out my costs, it may help by encouraging me to increase my prices/profits.

For your situation some more work may be needed. You say you multiply materials cost by 3.5 to get overall costs, but how did you come up with this formula? Have you figured out your overhead? Electricity, phone, rent, mortgage, machinery, vehicle, gas, etc. - then added in your hourly labor rate?

When I do a quote it is cost of materials + 30%, then add in a weekly rate which includes overhead and labor, then add a percentage for profit. There are still places where I can fall short, (like estimating time to build), but when I have accounted for all my expenses and have a cushion I should not lose money. And if you have all of this worked out for the next job, neither should you.

Really what I am trying to get out of asking about the pricing on this kitchen is what it would normally cost (whatever normal is), so I can tell them, "If someone asks you how much the kitchen was, you tell Xk, not 11k." Therefore someone won't be calling me up looking for quality cabinets for cheap.

The reason us giving you pricing won't help is because the biggest difference in costs is regional. Of course there are many other factors we don't know including the quality of your work/finish, what kinds of hardware, drawer construction and etc. But even with all that detailed information you have a huge geographical variation to deal with. I would guess you could get quotes from 10k - 40k.

I'll give you the same advice I gave last week to a similar question. Get a copy of last months Cabinetmaker magazine. They have cabinet shops across the country to contribute quotes for specific jobs. I think you will be surprised at how much variation there really is in this business.

I wish I would have found this site about two weeks before I got started. And perhaps my bid was not too far off, I am just too slow for this go around. But it’s all part of the learning curve. For instance, I had never made a corner cab that is 45 degrees to the rest of the cabs so that took some extra time.

On top of this the software will optimize your sheet goods and print out cutting diagrams to help you cut waste and show you positioning of all of your dados, hardware holes etc, and will print labels for all of these parts to organize them.

If you build doors and drawers in house it will cut list them for you, and if you outsource it will give you the information for your purchase order. It is well worth looking into.

If you don't take advantage of the eCabinet Systems, look into one of the many other software packages that are available. They will save you a lot of money in the long run.