Question

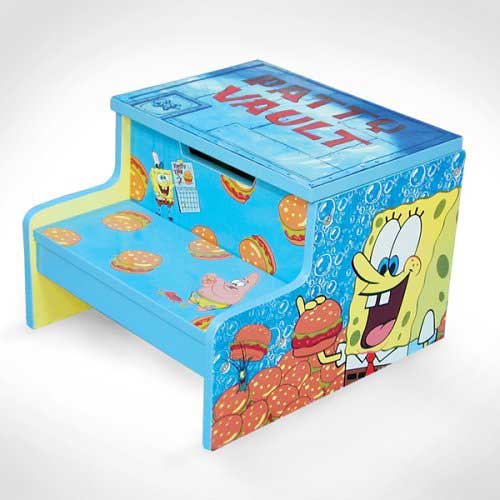

I was looking at the unit below, and was wondering how the images were printed onto the wood. Does anyone have any ideas?

Forum Responses

(Laminate and Solid Surfacing Forum)

From contributor J:

Thermo foil might be one way. Another might be the use of silk screen presses. A base color coat and a 3 screen press could do the same thing as well. It does not take a lot of capital or equipment to do silk screen and it is great on small production runs. It is nearly an art form, so it takes time to master.

To reproduce something this complex economically, contact a sign shop or digital printing company and order a self-adhesive vinyl print with a polyester top laminate (for scuff resistance). Digital art must be provided and it will cost about $100 to cover that much area. Exposed edges of the decal, however, are vulnerable to being caught and peeling away. They should be overlapped with a trim cap of plastic, or perhaps a 2 part resin bead that seals the edge.

Some new flat bed digital printers are coming out that will image uv ink directly to the surface (it must be bright white). This would be a superior finished product, and it would be very durable and have no plastic finish.

Large exhibit or screen-printing houses would have them, but getting them to do a small job would be the challenge. A very low-tech solution is to use a digital paper print (or color xerox) and deco page it. Use a bar top epoxy over the surface for good durability.