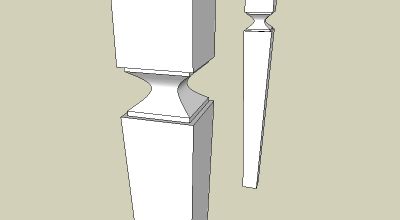

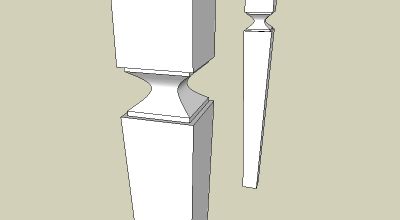

Shaping Tapered Table Legs

Tips on profiling and tapering custom table legs when there's no easy outsourcing option. February 20, 2008

Question

I'm making a table for a client and they have shown me a picture of a table with a leg shaped as in the picture. I have contacted my CNC machine shop and the quote was £400-£500 - too much for this job. The shape I'm talking about is the curve - the rest I can do. As the job is to be painted and made from poplar, I had thought of making the shape on the bandsaw as a separate piece and joining it to the top and bottom part of the leg. Has anyone got other suggestions?

Forum Responses

(Cabinetmaking Forum)

From contributor L:

Sounds like the CNC guy didn't want the job. I assume you need four legs, so do the initial cutouts with a router bit to hog the shape out and then use a file or a belt sander to finish it. Should take about 3/4 hour per leg.

From contributor D:

We have made these on the drill press. Pair them up and clamp together under a bit of whatever diameter for the cut/bore. A sharp, rim guided Forstner bit works the best. Drill it out, rotate each leg 90 degrees, and repeat. The last bore is the one that is tough, breakout wise. Holding your breath may help. I'd save the little rebates until after the bores.

Who needs a CNC? You are seeing the same thing I see with the machine intensive - the programming and lack of "shift and run" runs the costs up prohibitively. Just my opinion, and they tell me dinosaurs are extinct. But a little improvisation goes a long way. Now, when you get to the octagonal, heavily molded legs, it's either a rotating back knife lathe, a CNC, or intensive improvisation.

From contributor P:

Cut them out on the drill press, but instead of drilling all the way through in one pass on the first cove, drill halfway or so and flip it over, finishing the cut in the middle of the piece. Drill the rest from the outside, finishing in the middle. Then take a rasp and shape to final and clean it up with hand sanding.

From contributor B:

Why not just buy them?

From contributor P:

That takes all the fun out of it.

From contributor V:

I have done them on a table saw before. You mitre set at an angle and cut a cove 1/8 inch at a time. You will have to play around with it to get the angle and amount of cove.

From the original questioner:

Thanks for all the responses. The drill press one sounds very interesting - I hadn't thought of that one. I would buy them if I could, but I haven't found a supplier here.

From contributor W:

I just got a quote from Osborne Wood Products for 4 custom turned legs in soft maple for about $350USD. With the dollar being so low right now, the cost to you would be very good. They have quick turnaround time and excellent customer service.

From contributor T:

I have done these for my pieces and they look great. I would line the square pieces and clamp up before tapering, use a guide and rout out the center with a 5/8" round nose bit (you have Freud there, don't you?). Rotate squares until all sides are done, then mount a proper sized 45 degree chamfer bit with bottom bearing and finish off. Bearing rides in the deep radius groove. Do the rebates before you taper and sand. Try a sample - you'll like it! Just make sure all your round bottom grooves are lined up before chamfering. I use a 5/8 inch wood dowel.