Shop-Built Bandmill Blade Sharpeners

Sawmillers share ideas for blade-sharpening rigs. August 29, 2006

Question

Does anyone have the Suffolk video that shows how to make your sharpener out of a grinder? They no longer sell it, and I would like to acquire the information. Also any links to pictures of similar grinders would be appreciated.

Forum Responses

(Sawing and Drying Forum)

From contributor A:

Buy a chainsaw sharpener from Harbor Freight and modify it to sharpen your blades. Not real fancy, but it works and only costs about $10 more than cost of chainsaw sharpener -less if you have little bit of junk steel laying around. You will still need a method to adjust set on blade before sharpening. This is very important and too often overlooked or ignored.

From contributor B:

Come on guys, you can't expect to sharpen blades with a chainsaw grinder. The reason why the video is no longer available is because this is dangerous. If you don't set the blade and grind the whole profile of the blade you don't remove the microscopic cracks out of the gullet. End result - sharpen maybe twice and the blade breaks. That is why all the good sharpeners grind the whole tooth.

From contributor C:

I never saw a video from Suffolk. I just simply made a blade grinder that sharpens the blade, including the gullet. I did not know I was not supposed to be able to do it. The grinder came from Harborfreight.com and cost about $50-60. The rest was made from angle iron and some wood.

Have sharpened some blades 8-10 times and in two years have never had a blade break. In the pictures, the grinding stone needs to be reshaped I just took some photos to show how easy it is to build. If you look at one of the automatic sharpeners you will see that this is just a manual version of them.

Pictures attached:

1. Overall view

2. Grinding a tooth

3. Ready to advance to next tooth

4. Tooth advanced

5. Blade lock

6. Back view showing how to adjust angle

7. Side view

6. Side view

Click here for full size image

From contributor C:

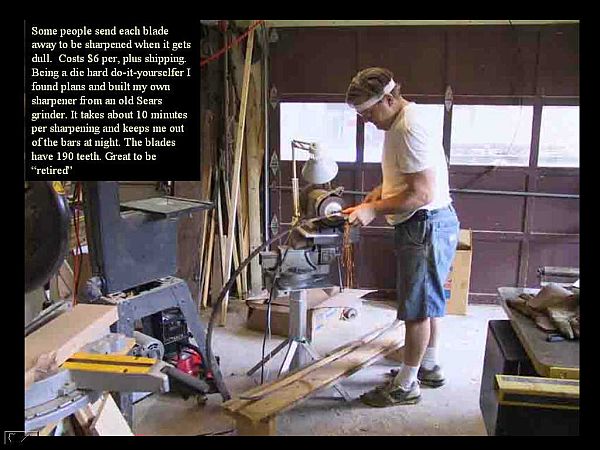

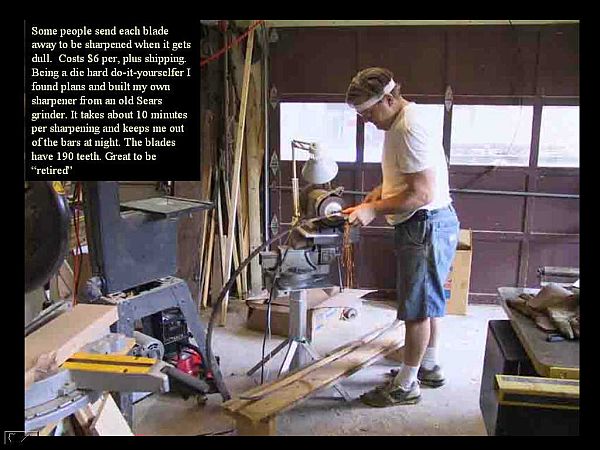

Here's a picture of the grinder in action. This is a part of a Powerpoint presentation I did on my woodworking projects.

Click here for full size image

From contributor D:

To contributor C: Your sharpener looks just like mine. I like your blade caddy - mind if I steal the idea? How wide of a grindstone do you use? I got the one from Timberwolf that is 1/2" or 5/8". I profiled it and can get about 75% of the tooth profile with it. I miss the middle of the back of the tooth. I have a blade that I have sharpened probably ten times; I took a bunch of teeth off on a nail early on in it's life and have almost ground teeth back! Do you set? I don't yet but have plans to make my own setter.

A question for those with commercial sharpeners: how much of the tooth do the factory made sharpeners grind? Do they go over the entire tooth the first time? Or, to they take time to get the entire profile? I have blades I have sharpened several times that have not yet had the entire profile touched by the stone. The gullet and back (top?) of the tooth get ground but the middle of the back takes a while. I was thinking a wide profiled stone on a radial arm saw could profile the entire tooth with one swipe.

From contributor E:

To contributor C: How do you go about making so it would be automatic?

From contributor B:

To contributor D: At

Woodmizer they use a diamond wheel that grinds the complete tooth all at the same time - face, gullet, and the back of the tooth. To answer your other question, when I sharpen a blade, for the first .050 of blade height there is a small part of the back of tooth that does not get ground. You really need to set the blade every 2-4 sharpenings. I have a Cooks setter and love it. It may be slower than others but I know what the set is before and after with the dial indicator. Not every tooth has the same set as I am setting the teeth. It takes very small adjustments as your setting to get the .020-.022 set. I'm a real perfectionist. I want every tooth within .001 of each other. This really helps in the speed of when youíre cutting logs.

By the way I have a Woodmizer sharpener. It took several cams to get the machine to grind correctly. They make about 6 different cams for all the profiles out there. I got the grinder cheap because it was assembled wrong and no one could figure out how to fix it. It did take me a while, but the pusher finger that Cooks sells for the Woodmizer solved the problem.

From contributor C:

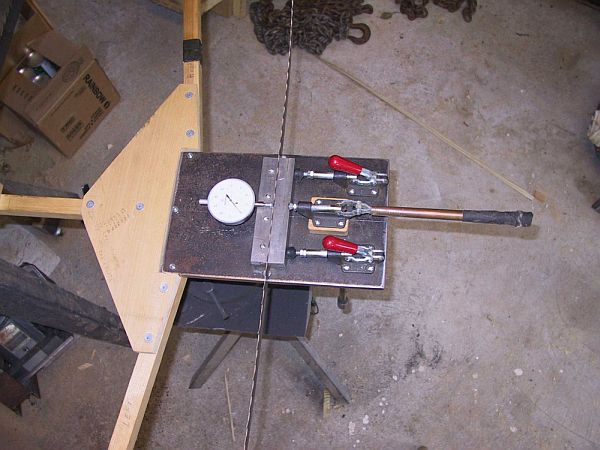

To contributor D: The grinding wheel I use is 3/8 in thick. Making it automatic is just too much work for the few blades I use. Here's a picture of my homemade blade setter. The base is sturdy 1/2 inch steel, the clamps are Destaco and the dial indicator is Mititoyo. It takes about 20 minutes per blade.

Click here for full size image

From contributor F:

To contributor D: I do exactly what you mentioned, a wide stone on a radial arm saw. You can do the whole profile, but be careful - it takes a one inch stone to grind the profile on a 7/8" pitch blade. Some arbors on the saws are not long enough. Be sure the blade is clamped tight. If not you will get chatter and a poor grind. I dress the wheel (silicon carbide) by sight and trial and error, but once you get what you want it lasts awhile if you don't take off to much in a pass. The radial arm saw lets you experiment with angles you can't obtain with many sharpeners.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor L:

It takes a lot of minute adjustments to get my grinder to cut the entire profile with my sharpener, but I always try to do it. I also use a 3/8" stone. I built my own tooth-setter out of a machinistís vice - sets 2 teeth at a time. My experience has been that if I am within 3-4 thou and the blade is sharp, it never wanders.

Comment from contributor G:

I own a

Woodmizer sharpener. Once the mechanical adjustments have been made to profile the entire tooth as close as possible, I dress the stone to complete the adjusting for that particular blade.