Solar kiln instruments

Other Versions

Spanish

Advice on controls for monitoring a solar kiln. October 2, 2001

Question

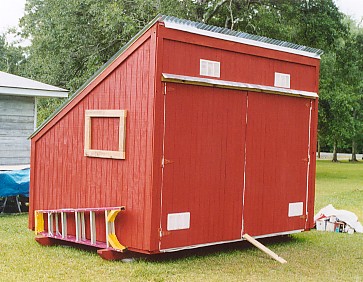

We are about to finish up our 1000 bf solar kiln, and would like some suggestions on thermometers and hygrometers. What are the minimum requirements? Everything else has been designed around information Dr. Wengert and others have written about these kilns.

Forum Responses

From contributor L:

I know a guy that has a kiln your size and he puts pins in some of the lumber and then runs leads outside so he can hook it up to a meter and check how it is drying. He is drying some lumber for me now and so far his system checks out close to what my meter reads.

You really do not need controls for the kiln, but if you want, a small electronic sensor from Radio Shack or similar for $30 will work. Or you can get a psychrometer (dry-bulb and wet-bulb).

The pin idea is okay, but remember that pins do not give accurate MCs until you get under 30% MC, at which point any degrade due to drying too quickly or too slowly has already happened.

Gene Wengert, forum technical advisor

From contributor L:

The guy I mentioned air-dries the load down to 25% before he loads it into the kiln. We put my lumber in at 20% and, by what the meter is reading, it will take a total of 45 days to get to 8%.

From the original questioner:

I have looked at the Taylor Mason's hygrometer and thought about building one using two digital thermometers. That way we can check on it from the outside.

As far as tracking MC, we are going to use weight based measurement. I am fixing to order a 10 kg digital scale with 1 g accuracy. I am also planning on wiring in an adjustable Snap Disc switch to turn the fans off, should it get too hot. It can be set to open up between 135 to 175 F or 155 to 195 F depending on the model. At $8, it seems like cheap insurance.

One gram accuracy is really not good enough. Get something that will read more accurately. For example, you can get a triple beam scale that weighs to tenths of a gram, but the maximum weight is 2600 grams. For many that is okay and these are under $150. You can spend as much as you want, but that is a good place to start.

Pins work pretty well when below 25% and if you plan to not put the lumber in the kiln until it is down to 25%, you might consider that.

It looks like you used soffit vents. How do you adjust the airflow?

From the original questioner:

We used the soffit vents because they were a cheap and easy way of keeping the bugs out. We are going to install some sliding air registers over them. I have thought of using some plexiglass panels in aluminum C channel mounted on 1x facers around the vents. I think that would look good and work well.

PVC material was used in this construction. I was under the impression that it was not as good as polycarbonate. Apart from cost, what was your reason for going with PVC?

From the original questioner:

We chose the PVC due to price and color. This was the clearest of the two that we could buy locally. These sheets were only $13 per 12' length. The PolyCarb panels were $25 each. We will see how long these hold up, and change to PolyCarb next time.

Just remember that PVC is UV unstable in its natural state. They can add retardants, but most have significant side effects. Believe me, I've seen very large companies have problems with this. Ever see a copier with yellow plastic in one place and white in the other? I'm not sure how this will effect lumber drying.